Ignition and flame-out protective device used on infrared ray stove

A flame-out protection and infrared technology, applied in the field of flame-out protection device and pulse discharge ignition, can solve the problems of burning leads, inconvenient installation and maintenance, and high cost of the lower ignition device, so as to solve the insecurity, improve the popularization effect, and improve the aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

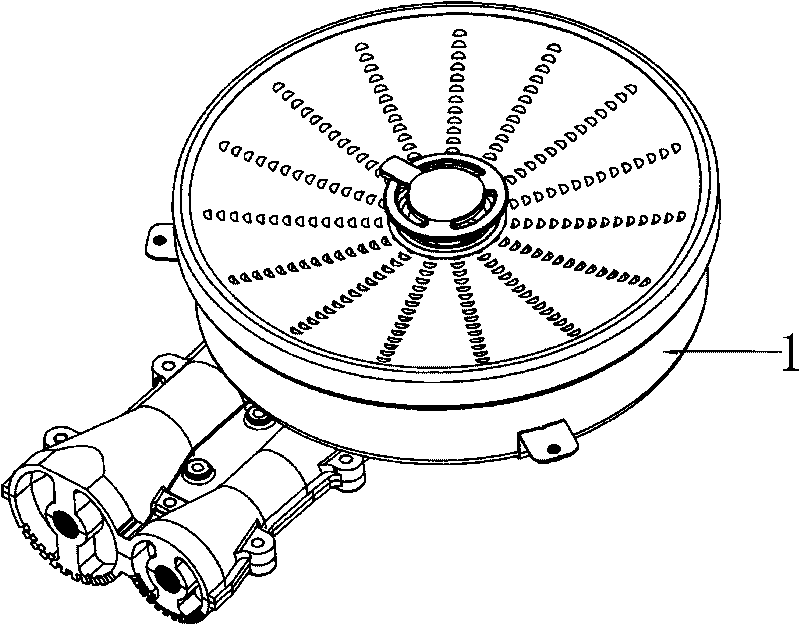

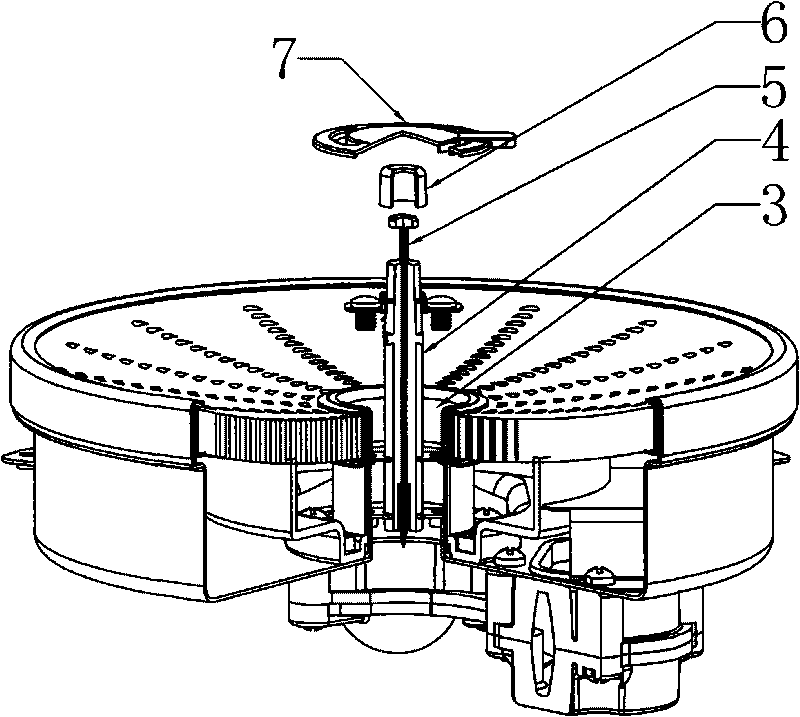

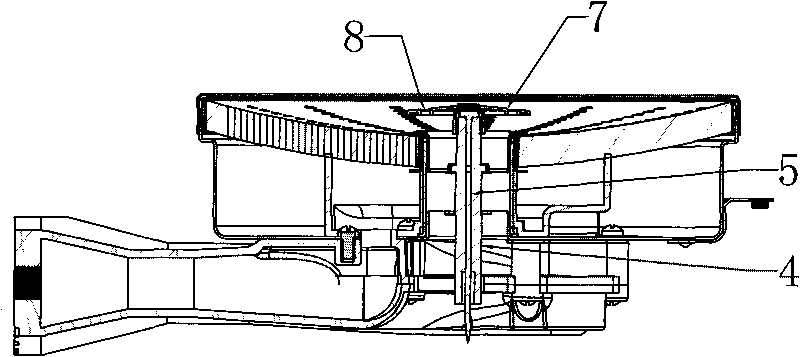

[0028] Embodiment 1: see attached figure 1 to attach Figure 5 , the pulse discharge ignition and flameout protection device for infrared cookers described in this embodiment is installed at the gas outlet on the inner side wall of the central ventilation channel 3 of the furnace cavity 1, and the device includes a high temperature resistant insulating sleeve 4 , conductive needle 5, conductive connecting body 6, and electrode piece 7, wherein, the high temperature resistant insulating sleeve 4 is installed in the central ventilation channel 3, the conductive pin 5 is located in the high temperature resistant insulating sleeve 4, and the high temperature resistant insulating sleeve 4 is made of ceramic and non-conductive Made of insulating material, and fixed in the central ventilation channel 3 by means of screws or mechanical connections. The lower end of the conductive needle 5 passes through the high-temperature-resistant insulating sleeve 4 and is connected with the elec...

Embodiment 2

[0030] Embodiment 2: see attached Figure 6 , attached Figure 7 The difference between this embodiment and Embodiment 1 is that the upper end of the conductive needle 5 below the airflow blocking area 8 has a bent portion 2 extending laterally. The bending part 2 has a conductive function, which can make the gas in the recirculation area easier to ignite. And the airflow slot 11 of this embodiment is a circular hole or an oval hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com