Fuel-cell anode catalyst and preparation method thereof

A technology for fuel cells and catalysts, applied in battery electrodes, chemical instruments and methods, catalysts for physical/chemical processes, etc. Research and other issues to achieve the effect of improving catalytic activity and stability, simple preparation process and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

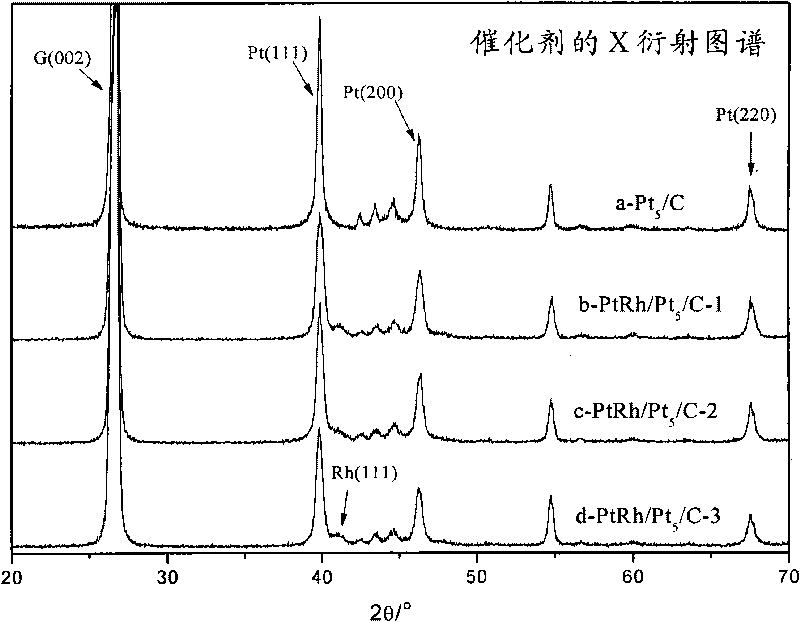

Embodiment 1

[0015] 0.5g of graphite powder is added into 15ml of ethylene glycol aqueous solution with a volume ratio of 1:1, stirred and heated up to 80°C, treated with ultrasonic waves for 1.5h, kept at 80°C and under the action of ultrasonic waves, 16.7ml of chloroplatinic acid aqueous solution (0.077mol / L) was added dropwise into the mixed solution, after stirring for 1 h, 15 ml of formaldehyde aqueous solution with a formaldehyde content of 18.5% was added dropwise and the reaction was continued for 1 h. The resulting suspension was repeatedly washed with ultrapure water and filtered until no chloride ions existed, dried in vacuum at room temperature for 30 minutes, placed in a tube furnace, and roasted in an air atmosphere at 400 ° C for 4 hours to obtain platinum-containing 5% by mass of Pt / C catalyst substrate, denoted as Pt 5 / C.

[0016] Weigh the Pt prepared in 0.5g embodiment 1 5 / C is added in the hydrogen bubbler, add 0.334ml chloroplatinic acid aqueous solution (0.077mol...

Embodiment 2

[0018] Prepare 0.5g Pt by embodiment 1 5 / C is added in the hydrogen bubbler, add 1.002ml aqueous solution of chloroplatinic acid (0.077mol / L), after passing into hydrogen bubble 1h, add 2.02ml rhodium chloride aqueous solution (0.048mol / L), bubble 1h, Then add 1.002ml of chloroplatinic acid aqueous solution (0.077mol / L), continue bubbling for 1h, and let stand for 10min. The resulting suspension was repeatedly washed with ultrapure water and filtered until no chloride ions existed. After vacuum drying at room temperature for 30 minutes, it was placed in a tube furnace for 4 hours at 300°C and then cooled to room temperature. Finally, it was dried at 150°C Under hydrogen reduction, the supported surface alloy catalyst is obtained, denoted as: PtRh / Pt 5 / C-2, the mass ratio of platinum to rhodium in the surface alloy is 0.3:1, and the mass ratio of PtRh alloy to substrate Pt is 0.52:1.

Embodiment 3

[0020] Prepare 0.5g Pt by embodiment 1 5 / C was added to the hydrogen bubbler, and 2.672ml of chloroplatinic acid aqueous solution (0.077mol / L) was added. After bubbling with hydrogen for 1h, 2.02ml of rhodium chloride aqueous solution (0.048mol / L) was added and bubbling for 1h. Then add 2.672ml aqueous solution of chloroplatinic acid (0.077mol / L), continue bubbling for 1h, and let stand for 10min. The resulting suspension was repeatedly washed with ultrapure water and filtered until no chloride ions existed. After vacuum drying at room temperature for 30 minutes, it was placed in a tube furnace for 4 hours at 300°C and then cooled to room temperature. Finally, it was dried at 150°C Under hydrogen reduction, the supported surface alloy catalyst is obtained, denoted as: PtRh / Pt 5 / C-3, the mass ratio of platinum to rhodium in the surface alloy is 0.8:1, and the mass ratio of PtRh alloy to substrate Pt is 0.72:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com