Heat-conducting fluid for reducing internal temperature rise of mass concrete and preparation method thereof

A large-volume concrete and heat-conducting fluid technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of insufficient stability of microcapsule suspensions and achieve high suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

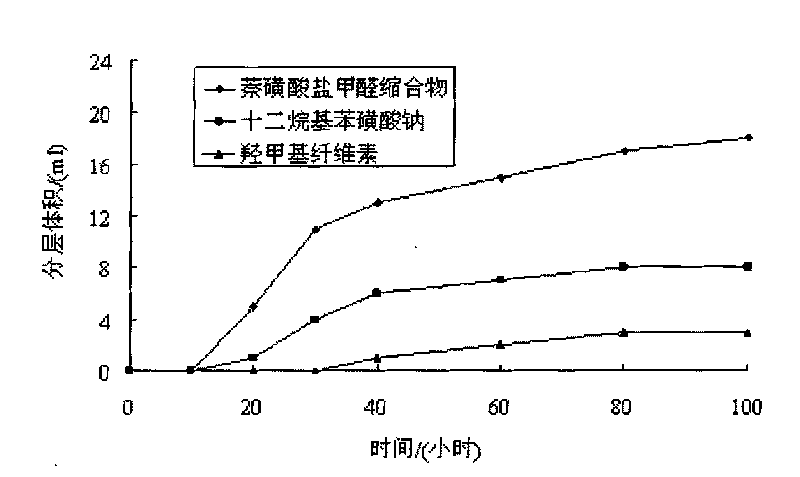

Method used

Image

Examples

Embodiment 1

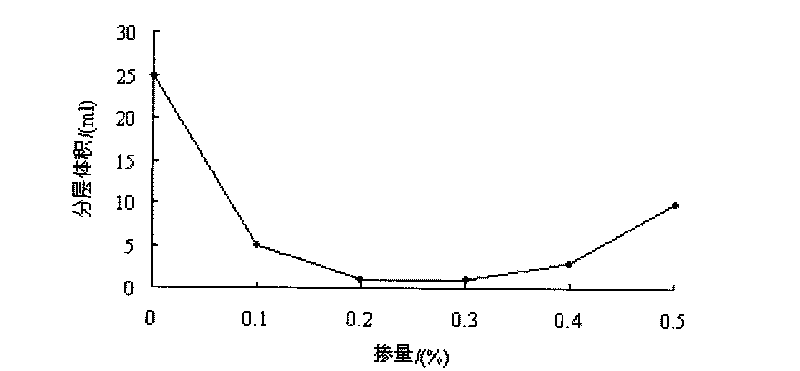

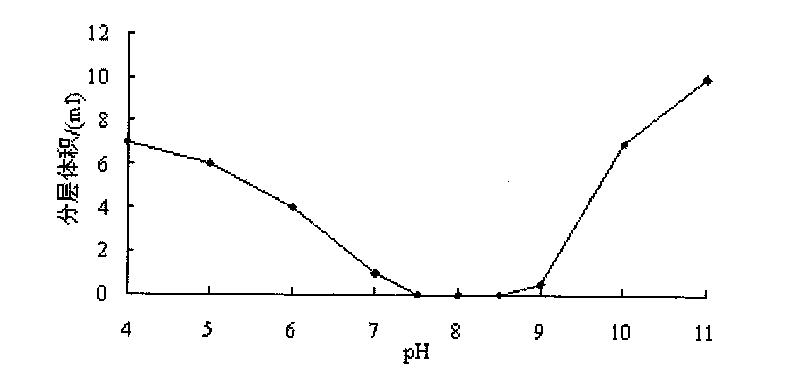

[0029] A heat-conducting fluid used to reduce the internal temperature rise of mass concrete is a microcapsule suspension, with hexadecane microcapsules as the dispersant, water as the liquid carrier, and 0.25% wt of hydroxymethyl cellulose as the Dispersant, the pH of the liquid system is pH=8, the concentration of the phase change material hexadecane microcapsules is 20%wt, the wall material of the hexadecane microcapsules is polyurea-melamine resin, and the phase transition temperature is 17.42°C, the phase transition enthalpy is 147.93J / g, and the particle size range is 1.51-10.48um.

[0030] The specific preparation process of the heat transfer fluid used to reduce the internal temperature rise of mass concrete is as follows:

[0031] Dissolve hydroxymethyl cellulose in water at 70°C so that its molecules can fully stretch in water, prepare a 5%wt solution and cool to room temperature for use;

[0032] Add 1 mass part of hexadecane microcapsules to 4 mass parts of water,...

Embodiment 2

[0035] A heat-conducting fluid used to reduce the internal temperature rise of mass concrete is a microcapsule suspension, with hexadecane microcapsules as the dispersant, water as the liquid carrier, and 0.2% wt of hydroxymethyl cellulose as the Dispersant, the pH of the liquid system is pH=7, the concentration of the phase change material hexadecane microcapsules is 10%wt, the wall material of the hexadecane microcapsules is polyurea-melamine resin, and the phase transition temperature is 17.42°C, the phase transition enthalpy is 147.93J / g, and the particle size range is 1.51-10.48um.

[0036] The specific preparation process of the heat transfer fluid used to reduce the internal temperature rise of mass concrete is as follows:

[0037] Dissolve hydroxymethyl cellulose in water at 60°C so that its molecules can fully stretch in water, prepare a 5%wt solution and cool to room temperature for use;

[0038] Add 1 mass part of hexadecane microcapsules to 9 mass parts of water, ...

Embodiment 3

[0041] A heat-conducting fluid used to reduce the internal temperature rise of mass concrete is a microcapsule suspension, with hexadecane microcapsules as the dispersant, water as the liquid carrier, and 0.3% wt of hydroxymethyl cellulose as the Dispersant, the pH of the liquid system is pH=9, the concentration of the phase change material hexadecane microcapsules is 25%wt, the wall material of the hexadecane microcapsules is polyurea-melamine resin, and the phase transition temperature is 17.42°C, the phase transition enthalpy is 147.93J / g, and the particle size range is 1.51-10.48um.

[0042] The specific preparation process of the heat transfer fluid used to reduce the internal temperature rise of mass concrete is as follows:

[0043] Dissolve hydroxymethyl cellulose in water at 50°C so that its molecules can fully stretch in water, prepare a 5%wt solution and cool to room temperature for use;

[0044] Add 1 mass part of hexadecane microcapsules to 3 mass parts of water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com