Method for preparing functional fluorine-bearing monomer by vertical-tube type catalytic reaction

A functional, standpipe-type technology, applied in the field of preparation of functional fluorine-containing monomers, can solve the problems of reduced service life and mechanical properties of exchange membrane materials, so as to eliminate energy waste, improve utilization rate, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

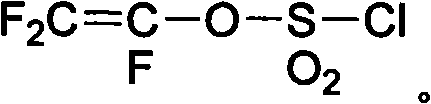

[0043]The vertical pipe reactor that is equipped with circulating cooling / heating system, temperature control system and is filled with gac catalyst is vacuumized inside the system by the decompression system at the top, (the inner diameter of the vertical pipe reactor is 160mm, and the length is 3500mm, Hastelloy material) filled with nitrogen for three times until the oxygen content is controlled below 10ppm, vacuumed to -0.1MPa, closed the pressure reducing valve, adjusted the temperature of the circulating water to keep the internal temperature of the reactor at 0°C, from the lower part of the tubular reactor Slowly add tetrafluorosultone (molecular formula: FO 2 SCF 2 COF), trifluorovinyl sulfate, and anhydrous hydrogen fluoride are mixed liquid materials with a molar ratio of 1:1:5, and the residence time of the liquid materials in the reactor is controlled by a feed flowmeter to be 10min to maintain continuous feed and discharge. The product with the designed structure...

Embodiment 2

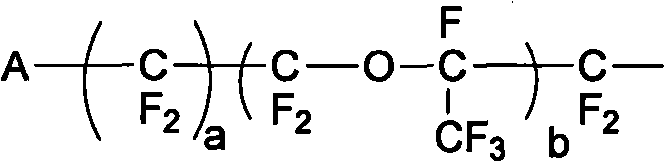

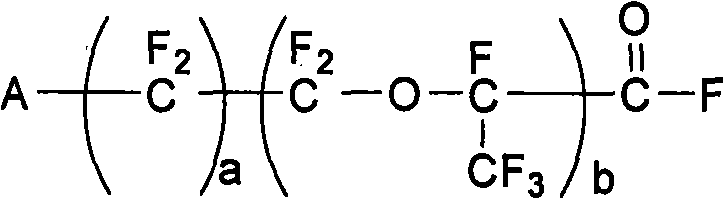

[0046] A vertical tube reactor equipped with a circulating cooling / heating system and a temperature control system filled with activated carbon, macroporous molecular sieves, and a mixed catalyst with a mass ratio of porous alumina of 1:1:1 was used to pump the inside of the system through the top decompression system. Vacuum, (the inner diameter of the standpipe reactor is 180mm, the length is 4000mm, made of Hastelloy alloy) filled with nitrogen and replaced three times until the oxygen content is controlled below 10ppm, vacuumed to -0.1MPa, closed the pressure reducing valve, and adjusted the circulating water The temperature inside the reactor was controlled at 3°C, and perfluoro 5-acyl fluoride-4-methyl-3-oxa-pentanesulfonyl fluoride (molecular formula: FO 2 SCF 2 CF 2 OCF (CF 3 )COF), trifluorovinyl sulfate, and anhydrous hydrogen fluoride are mixed liquid materials with a molar ratio of 1:1:7, and the residence time of the liquid materials in the reactor is controlled...

Embodiment 3

[0049] A vertical tube reactor equipped with a circulating cooling / heating system and a temperature control system filled with activated carbon and a mixed catalyst with a mass ratio of porous alumina of 2:1 will vacuumize the inside of the system through the top decompression system, (vertical tube type The inner diameter of the reactor is 200mm, the length is 4100mm, and the Hastelloy material) is filled with nitrogen for three times until the oxygen content is controlled below 10ppm, then vacuumed to -0.1MPa, the pressure reducing valve is closed, and the temperature of the circulating water is adjusted to control the internal temperature of the reactor. Temperature at 5°C, slowly add perfluoro 3-acyl fluoride-propanesulfonyl fluoride (molecular formula: FO 2 SCF 2 CF 2 COF), trifluorovinyl sulfate, and anhydrous hydrogen fluoride are mixed liquid materials with a molar ratio of 1:1:6. The residence time of the liquid materials in the reactor is controlled by a feed flowme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com