Method for manufacturing chopped carbon fiber reinforced concrete

A technology of chopped carbon fiber and reinforced concrete, applied in chemical instruments and methods, clay preparation devices, mixing operation control, etc., can solve the problems of large number of carbon fibers, difficult to disperse carbon fibers, etc. dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

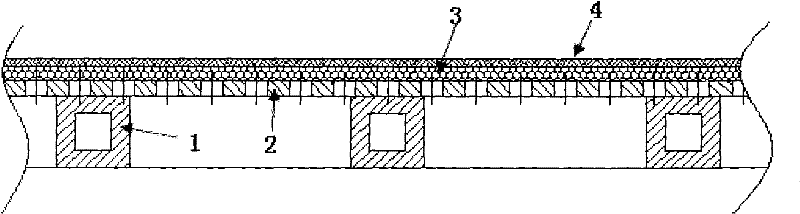

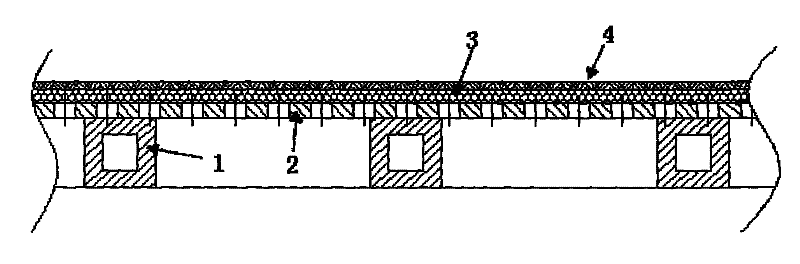

[0023] Prepare 25L of sodium carboxymethylcellulose aqueous solution with a mass concentration of 0.4%, and the water temperature is about 25°C. Add 10 g of PANEX35 chopped carbon fiber with a length of 6.4 mm from the Zoltek Company of the United States, and stir for 3 to 5 minutes while adding. Add a few drops of tributyl phosphate (manufactured by Wuhan Hongda Chemical Reagent Factory) while stirring, and the dosage is subject to the fact that there are no bubbles on the surface of the solution. Use filter to filter carbon fiber suspension, the total area of filter is 1m 2 , The structure of the filter net is shown in Figure 1.

[0024] After drying the filter cloth with carbon fiber in the drying equipment or in the sun, remove the chopped carbon fiber felt. The quality of the carbon fiber felt is weighed by an electronic balance with a sensitivity of 0.01 g, as shown in Table 1. Therefore, the mass average of carbon fiber felt is 11.27g / m 2 , wherein the glue conten...

Embodiment 2

[0026]Prepare 50 L of hydroxypropyl methylcellulose (molecular weight is 200,000) aqueous solution with a concentration of 0.4%, and the water temperature is about 25°C. Add 10g of 5mm PAN-based chopped carbon fiber from Shanghai Carbon Co., Ltd., and stir for 3 to 5 minutes while adding. Add a few drops of tributyl phosphate (manufactured by Wuhan Hongda Chemical Reagent Factory) while stirring, and the dosage is subject to the absence of air bubbles on the surface of the dispersant solution. Use filter to filter carbon fiber suspension, the total area of filter is 1m 2 , The structure of the filter net is shown in Figure 1. After drying the cloth with carbon fiber in the drying equipment or drying in the sun, remove the chopped carbon fiber mat.

[0027] Similar to Example 1, it is weighed by an electronic balance with a sensitivity of 0.01g: the average mass of carbon fiber felt is 11.48g / m 2 , the glue content is 12.9%, and the carbon fiber content is 87.1%.

Embodiment 3

[0029] Prepare 50 L of hydroxypropyl methylcellulose (molecular weight is 200,000) aqueous solution with a concentration of 0.4%, and the water temperature is about 25°C. Add 10g of 5mm PAN-based chopped carbon fiber produced by Taiwan Formosa Plastics Group, and stir for 3-5 minutes while adding. Add a few drops of tributyl phosphate (manufactured by Wuhan Hongda Chemical Reagent Factory) while stirring, and the dosage is subject to the absence of air bubbles on the surface of the dispersant solution. Use filter to filter carbon fiber suspension, the total area of filter is 1m 2 , The structure of the filter net is shown in Figure 1. After drying the cloth with carbon fiber in the drying equipment or drying in the sun, remove the chopped carbon fiber mat.

[0030] Similar to Example 1, it is weighed by an electronic balance with a sensitivity of 0.01g: the average mass of the prepared carbon fiber felt is 11.35g / m 2 , the glue content is 11.9%, and the carbon fiber conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com