Spiral fluted tap and method for processing same

A technology of spiral groove and tap, which is applied in the field of spiral groove tap and its processing, and can solve the problems of difficulty and inconsistency in the design of spiral groove milling cutter blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

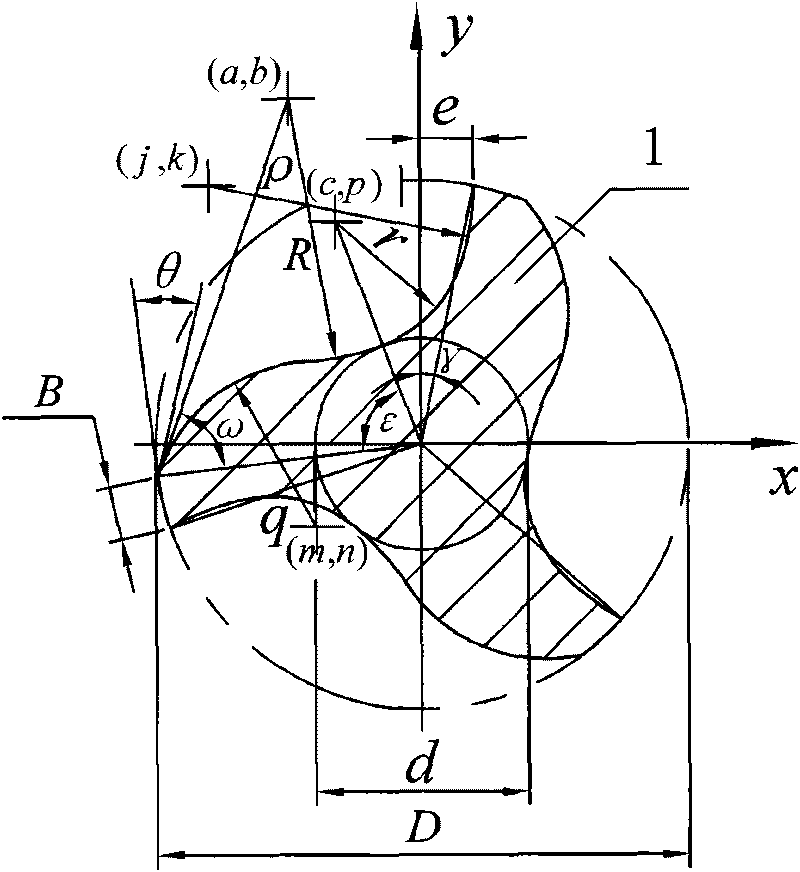

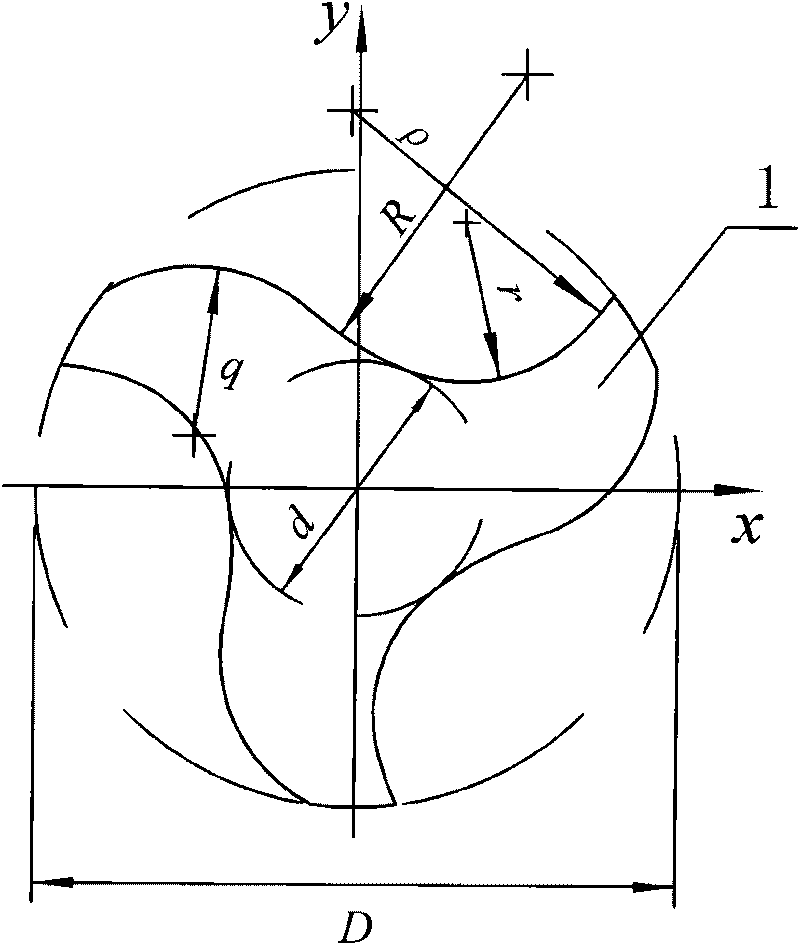

[0100] Such as figure 1 , figure 2 and image 3 As shown, in the present embodiment, the tap body 1 is an M10 tap, and the outer diameter D of the tap body 1 is required to be 10mm, the core diameter d=4mm, the width of the tap backside B=1.5mm, and the number of tap helical grooves Z =3, the offset of the cutting arc e=1.5mm, and the relief angle of the tap θ=25°. The radius of the cutting arc And the center coordinates (j, k) of the cutting arc are:

[0101] j = e - ρ = - 3.5 k = D 2 4 - e 2 ...

Embodiment 2

[0153] In this embodiment, the specific structure of the taps 1 to be processed and formed is exactly the same as that of Embodiment 1, that is, they are all M10 taps and the specific dimensions are the same.

[0154] The difference from Example 1 is that when the M10 tap is actually processed, the cutting tool used is a grinding wheel, and the outer diameter of the grinding wheel is D s=80mm, the shortest distance A=42mm between the central axis of the grinding wheel and the central axis of the M10 tap. Correspondingly, when using the grinding wheel to actually manufacture the M10 tap, the processing process includes the following steps:

[0155] Step 1, preparation before processing, this step is identical with embodiment 1.

[0156] Step 2, using a milling cutter fitted with a blade shape by a computer to process spiral grooves on the preliminary workpiece, the machining process is as follows:

[0157] 201. Use the computer to fit the blade shape of the grinding wheel use...

Embodiment 3

[0177] In this embodiment, the specific structure of the taps 1 to be processed and formed is exactly the same as that of Embodiment 1, that is, they are all M10 taps and the specific dimensions are the same.

[0178] The difference from Example 1 is that when the M10 tap is actually processed and manufactured, the step (h) is based on the plurality of discrete points (R i ,Z i ), and combined with the outer diameter of the milling cutter used, when the blade shape of the milling cutter used is fitted by the computer, the data modeling method is used for fitting, and when fitting, the multiple discrete points (R i ,Z i ) are drawn on a piece of coordinate paper, and then according to the multiple discrete points (R i ,Z i ) coordinate change rule to find a similar function with a fitting error smaller than the target error for segmental fitting, and then combine the segmental fitting functions to obtain the edge shape of the milling cutter. All the rest are the same as in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com