Method for preparing Ag-ZnO-doped electrical contact material

An electrical contact material, silver zinc oxide technology, applied in the direction of circuits, electrical switches, electrical components, etc., can solve the problem of contact resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

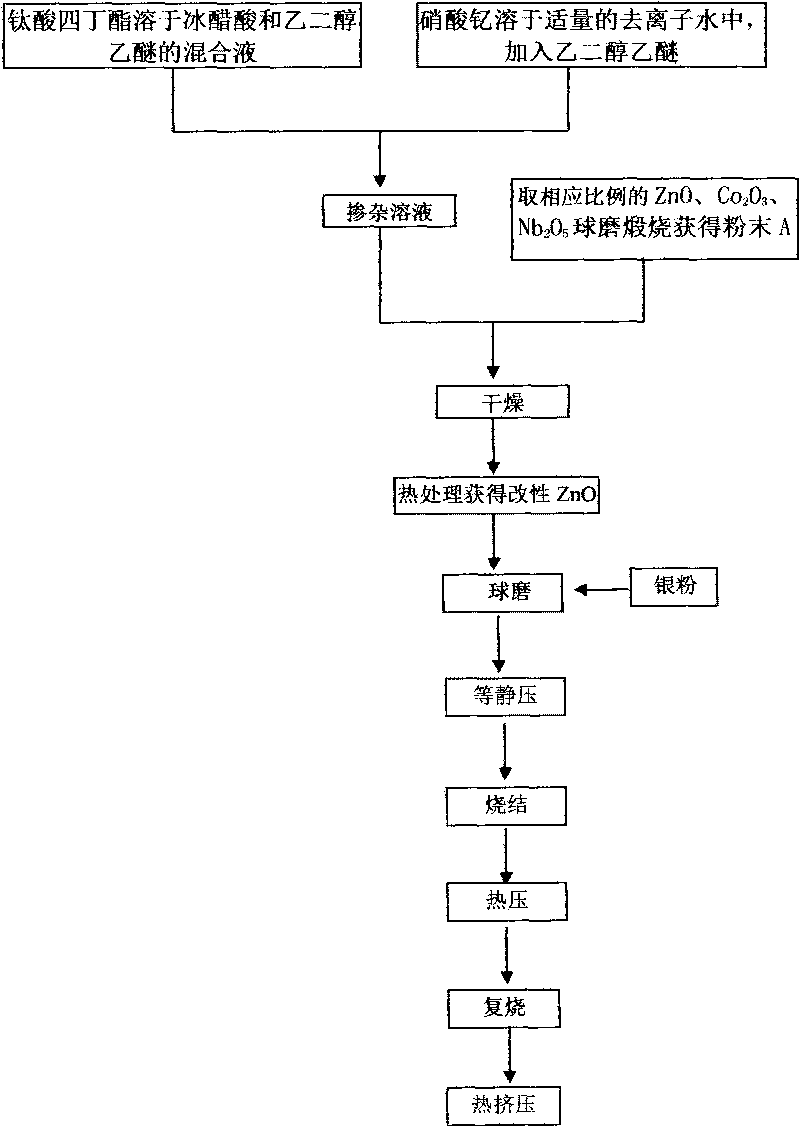

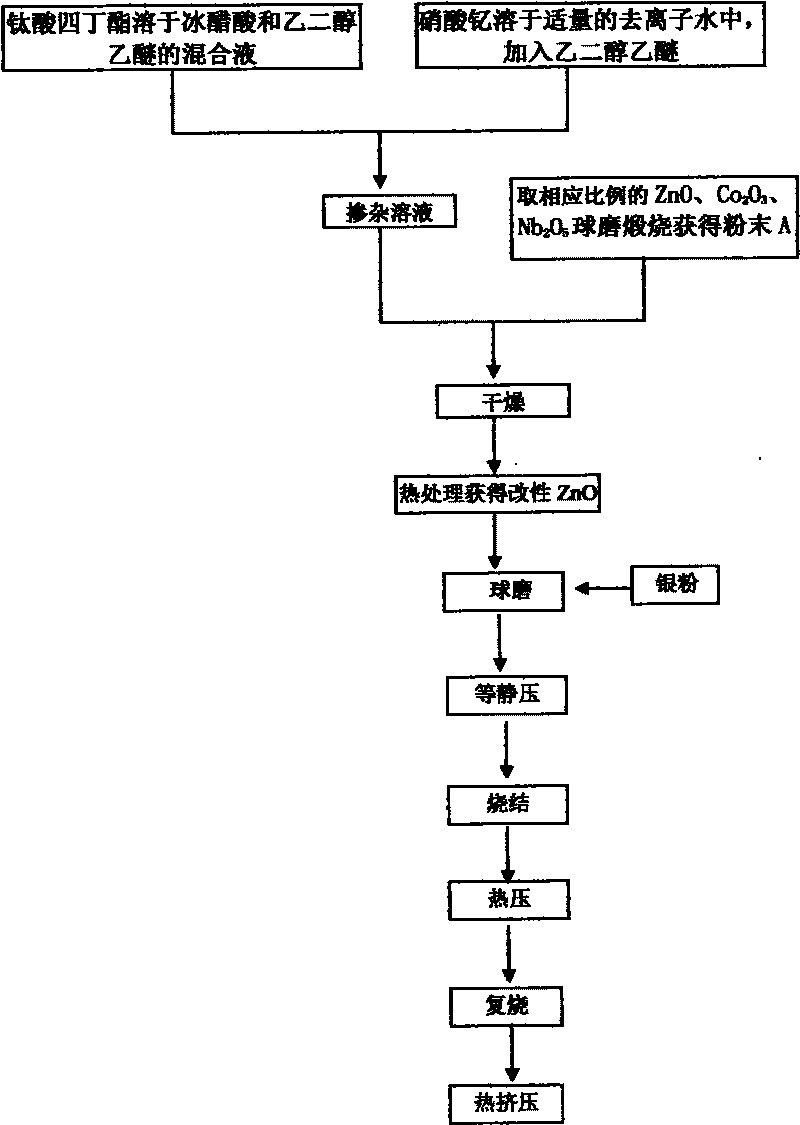

Method used

Image

Examples

Embodiment 1

[0032] 1. According to ZnO: Co 2 o 3 : Nb 2 o 5 (Molar ratio)=97.5:2.5:0.075 take the corresponding ZnO, Co 2 o 3 , Nb 2 o 5 Put it in a ball mill for 48 hours, then calcinate in air at 800°C for 1 hour, and then ball mill for 48 hours to obtain mixed powder A, wherein the ball milling speed is 50 rpm.

[0033] 2. According to ZnO: Co 2 o 3 : Nb 2 o 5 :Ti(OC 4 h 9 ) 4 (Molar ratio)=97.5: 2.5: 0.075: 0.05 Take a corresponding amount of tetrabutyl titanate and dissolve it in the mixed solution of glacial acetic acid and ethylene glycol ether, wherein glacial acetic acid: ethylene glycol ether (mass ratio)=1:2 ; Tetrabutyl titanate: (glacial acetic acid + ethylene glycol ethyl ether) (mass ratio) = 1:1, heated and stirred at 50-60°C until uniform and transparent, and obtained solution B.

[0034] 3. According to ZnO: Co 2 o 3 : Nb 2 o 5 : Y(NO 3 ) 3 =97.5:2.5:0.075:0.05 Dissolve the corresponding amount of yttrium nitrate in deionized water, add ethylene glyco...

Embodiment 2

[0046] 1. According to ZnO: Co 2 o 3 : Nb 2 o 5 (Molar ratio)=97.5:2.5:0.075 take the corresponding ZnO, Co 2 o 3 , Nb 2 o 5 Place it in a ball mill for 48 hours, then calcinate in air at 800°C for 1 hour, and then ball mill for 48 hours to obtain mixed powder A, wherein the ball milling speed is 200 rpm.

[0047] 2. According to ZnO: Co 2 o 3 : Nb 2 o 5 :Ti(OC 4 h 9 ) 4 (Molar ratio) = 97.5: 2.5: 0.075: 0.05 Take a corresponding amount of tetrabutyl titanate and dissolve it in the mixed solution of glacial acetic acid and ethylene glycol ether, wherein glacial acetic acid: ethylene glycol ether (mass ratio) = 2: 1 ; Tetrabutyl titanate: (glacial acetic acid + ethylene glycol ethyl ether) (mass ratio) = 1: 5, heated and stirred between 50-60 ° C until uniform and transparent, to obtain solution B.

[0048] 3. According to ZnO: Co 2 o 3 : Nb 2 o 5 : Y(NO 3 ) 3 =97.5:2.5:0.075:0.05 Dissolve the corresponding amount of yttrium nitrate in deionized water, add e...

Embodiment 3

[0060] 1. According to ZnO: Co 2 o 3 : Nb 2 o 5 (Molar ratio)=97.5:2.5:0.075 take the corresponding ZnO, Co 2 o 3 , Nb 2 o 5 Put it in a ball mill for 48 hours, then calcinate in air at 800°C for 1 hour, and then ball mill for 48 hours to obtain mixed powder A, wherein the ball milling speed is 150 rpm.

[0061] 2. According to ZnO: Co 2 o 3 : Nb 2 o 5 :Ti(OC 4 h 9 ) 4 (Molar ratio)=97.5: 2.5: 0.075: 0.05 Take a corresponding amount of tetrabutyl titanate and dissolve it in the mixed solution of glacial acetic acid and ethylene glycol ether, wherein glacial acetic acid: ethylene glycol ether (mass ratio)=1: 1 ; Tetrabutyl titanate: (glacial acetic acid + ethylene glycol ethyl ether) (mass ratio) = 1: 3, heated and stirred between 50-60 ° C until uniform and transparent, to obtain solution B.

[0062] 3. According to ZnO: Co 2 o 3 : Nb 2 o 5 : Y(NO 3 ) 3 =97.5:2.5:0.075:0.05 Dissolve the corresponding amount of yttrium nitrate in deionized water, add ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com