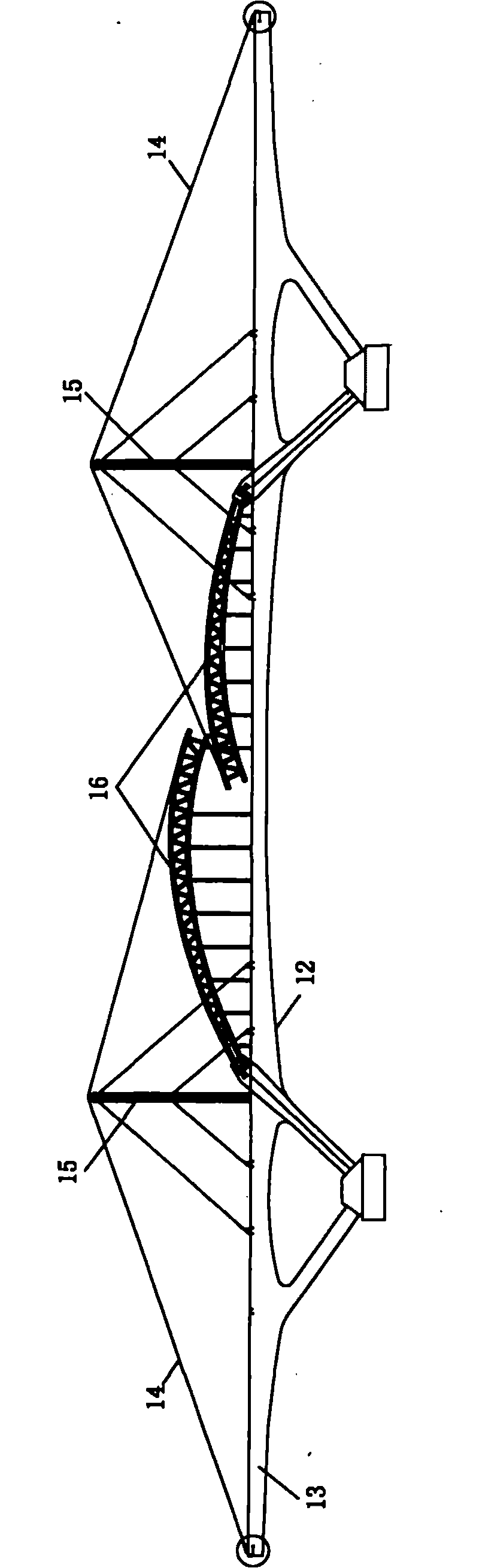

Reaction frame prestress anchoring system and method for vertical rotating steel pipe arch on concrete bridge

A concrete and reaction frame technology, applied in bridges, bridge forms, bridge construction, etc., can solve problems such as inflexible rear anchor design, influence of reaction frame pedestal on bridge deck, adverse effects of beam body, etc., and achieve easy anchoring ability , Anchorage design is flexible, and the effect of saving early construction design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

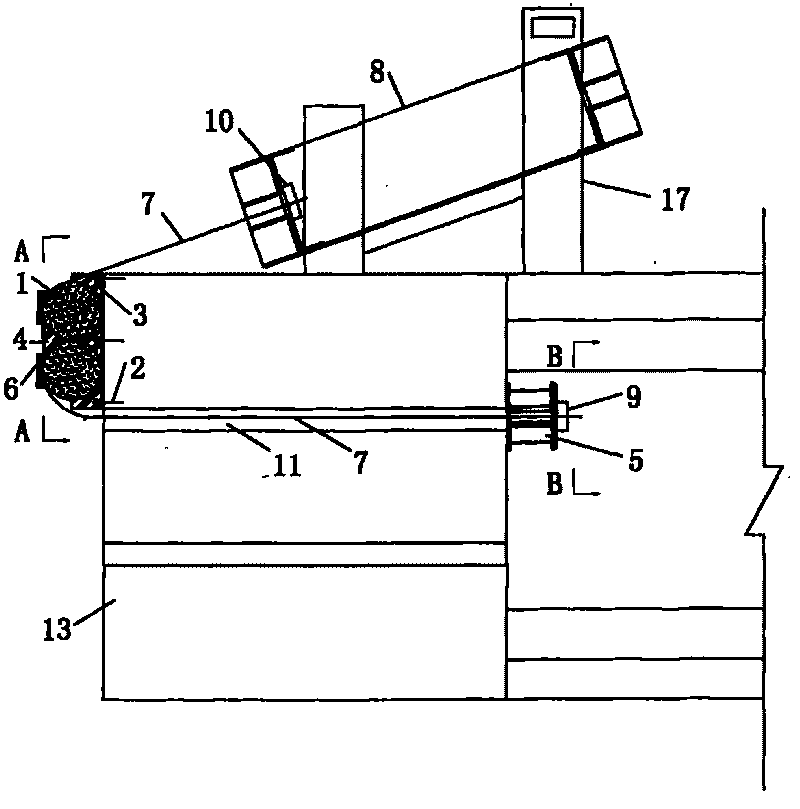

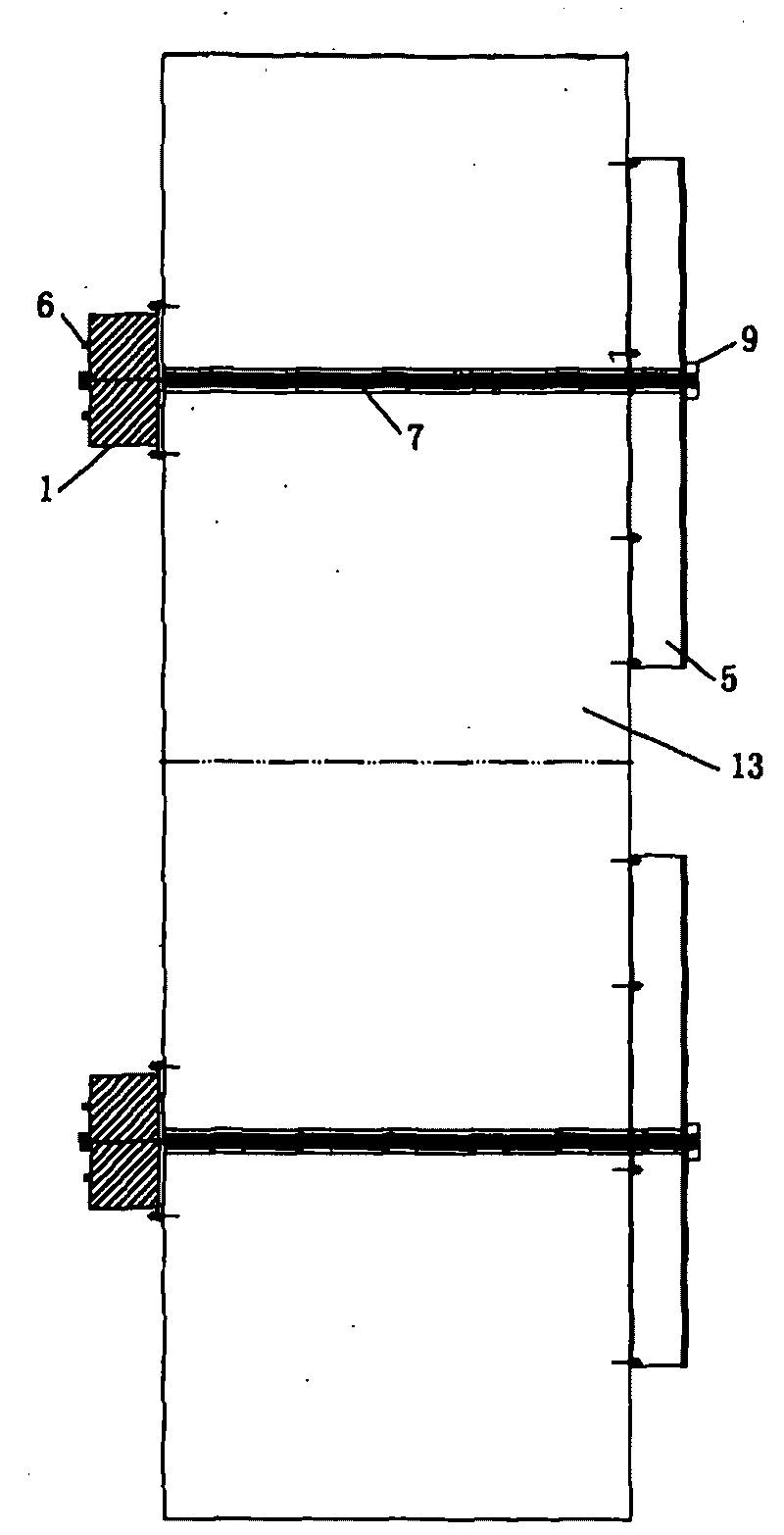

[0021] Cut 2 empty steel pipes (Q235), fill them with concrete to make them concrete steel pipes 1; fix the leveling steel plate 3 on the end of the beam body of the concrete bridge 12 (i.e., the side span solid section 13) by finishing rolled rebar 2; Two concrete steel pipes 1 are fixed on the leveling steel plate 3 through the connecting steel plate 4; the steel box 5 is made of I-beam and steel plate, and the steel box 5 is fixed on the inner side of the solid section 13 of the side span, as the anchorage of the reaction force frame 8 Pull end; the number of steel strands is calculated by the weight of the largest steel pipe arch that needs to be lifted, and anchors of corresponding specifications are selected; the steel strand 7 passes through the anchorage, steel box 5 and the designed reserve of the side span solid section 13 The hole 11 goes around the outer surface of the concrete steel pipe 1, and then connects with the reaction frame 8 through the anchorage, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com