FRP bar stretching and anchoring device

An anchoring device and tensioning device technology, which is applied in building maintenance, processing of building materials, structural elements, etc., can solve the problems of low shear strength and unsuitable bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

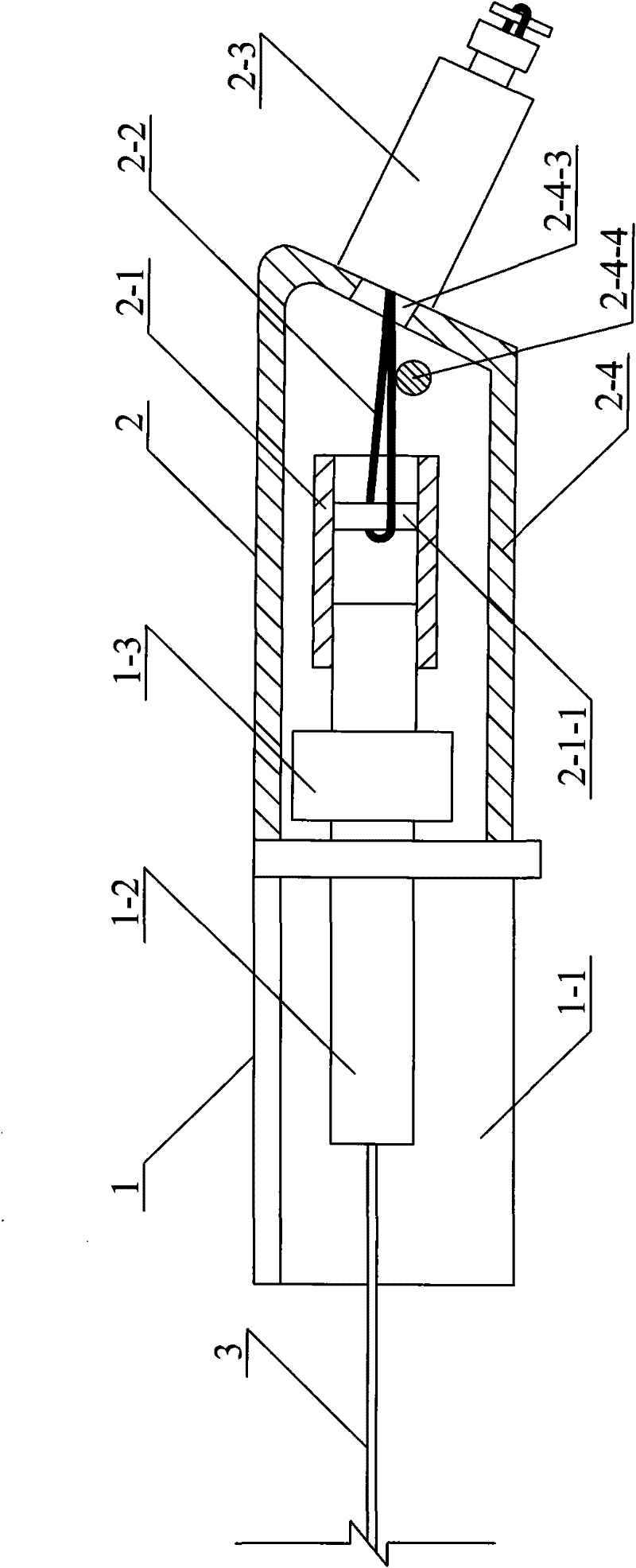

[0031] Such as figure 1 As shown, the FRP tendon tensioning and anchoring device in this embodiment includes an anchoring device 1 for anchoring FRP tendons and a tensioning device 2 for tensioning FRP tendons.

[0032] The anchoring device 1 includes an anchoring frame 1-1, a sleeve 1-2 and a nut 1-3.

[0033] The anchor frame 1-1 is fixedly connected to one end of the component to be reinforced. One end of the FRP tendon 3 is anchored and connected to the sleeve 1-2. External threads are provided on the outer surface of the sleeve 1-2, and the sleeve 1-2 is inserted on the anchor frame 1-1. The nut 1-3 is threadedly connected to the sleeve 1-2, and is used for limiting the position of the sleeve 1-2. The other end of the FRP tendon 3 can be connected to the other end of the member to be reinforced by another set of anchoring devices, or can be fixedly connected to the member to be reinforced by other methods.

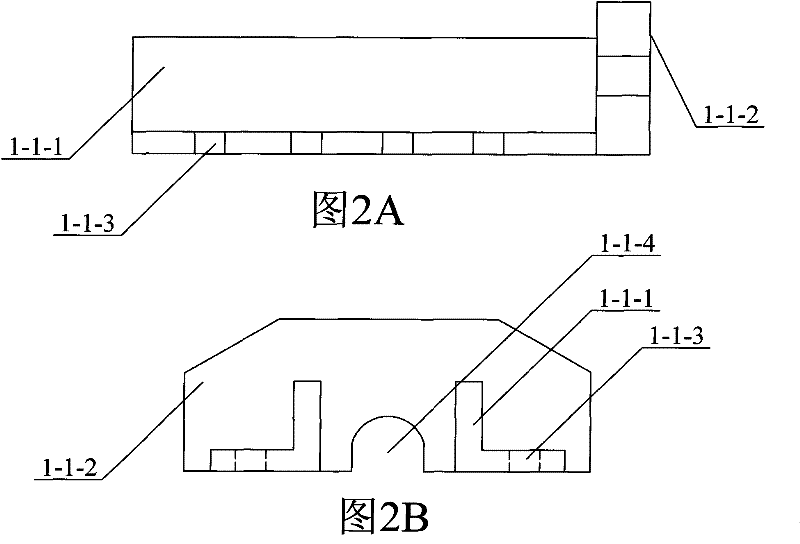

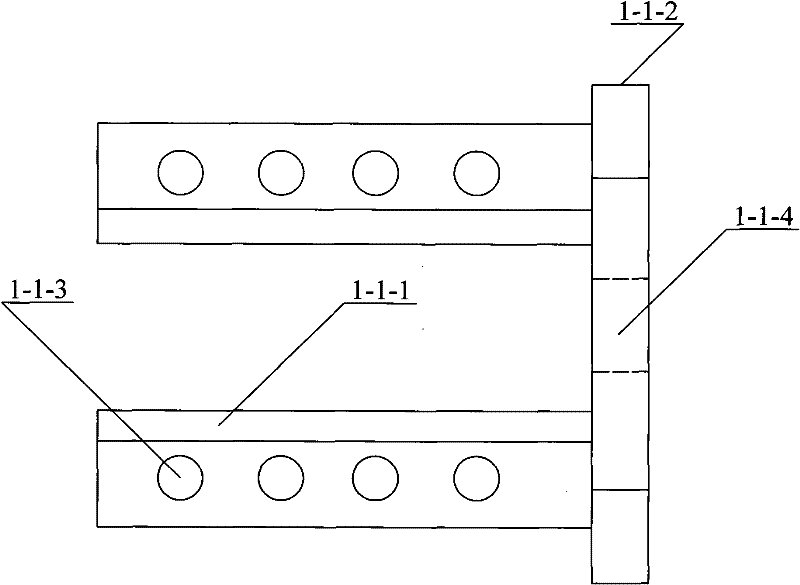

[0034] Such as Figure 2A , Figure 2B and Figure 2C As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com