Anchoring device for starting and receiving bases of shield tunneling machines with different diameters

A technology of anchoring device and shield machine, which is applied to mining equipment, tunnels, earthwork drilling and mining, etc. It can solve problems such as fracture and deformation of joints, and achieve the effect of increasing the support area and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

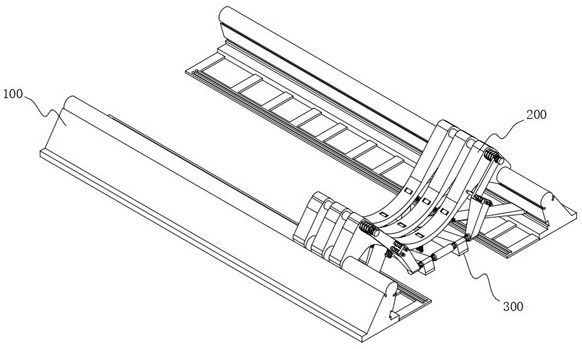

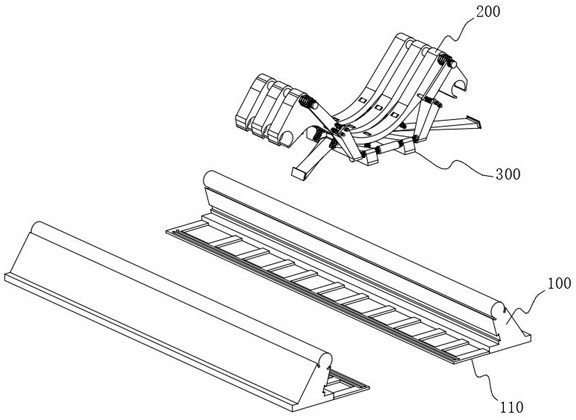

[0043] see figure 1 and figure 2 As shown, the purpose of this embodiment is to provide an anchoring device for launching and receiving bases of shield machines with different diameters, including a track 100 and a launching and receiving mechanism 200 arranged on the top of the track 100. The track 100 is used for Guide the originating and receiving mechanism 200 so that the originating and receiving mechanism 200 moves on the track 100, thereby realizing the transportation of the segments, but the segments are transported along with the drilling of the shield machine. During the period, the originating and receiving mechanism 200 stays on the track 100, so there will be a problem, that is:

[0044] The shield machine will generate vibration force during the drilling process. If the originating and receiving mechanism 200 cannot be stably fixed, the originating and receiving mechanism 200 will move on the track 100, and then the connection will easily break due to the vibra...

Embodiment 2

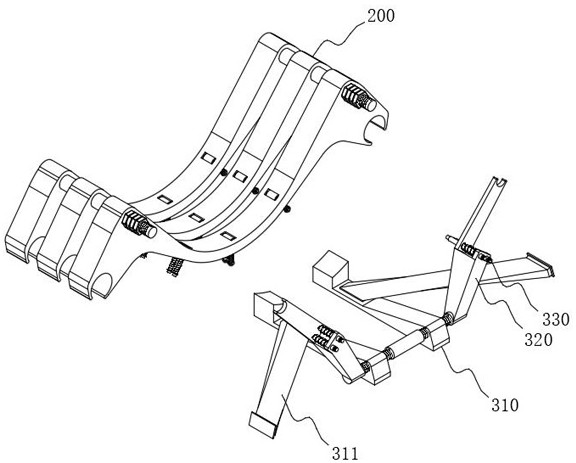

[0046] This embodiment specifically discloses the anchor 330, please refer to Figure 5 As shown, the anchor member 330 includes an anchor rod 331, which is fixedly connected to the adapter frame 321. When in use, the anchor rod 331 is nailed into the soil layer, so as to realize the anchoring of the originating and receiving mechanism 200. .

[0047] In addition, there is another implementation, please refer to Fig. figure 2 and7 As shown, the inner side of the track 100 is provided with an expansion panel 110, and an anchor groove 111 is provided on the top of the expansion panel 110. The anchor member 330 includes an anchor rod 331, and an outer plate 332 is arranged on the outside of the anchor rod 331. The outer plate 332 is fixedly connected with an outer tube 3321, the anchor rod 331 is threadedly connected with the outer tube 3321, the end of the adapter frame 321 is fixedly connected with an end plate 3211, the outer tube 3321 is slidingly connected with the end pla...

Embodiment 3

[0053] This embodiment discloses the sending and receiving mechanism 200, please refer to Figure 9 As shown, the originating and receiving mechanism 200 includes a connecting seat body 210 and an extended seat body 220, the size of the connecting seat body 210 and the extended seat body 220 are matched, and one side of the connecting seat body 210 is provided with a connecting screw rod 211, and the extended seat body The body 220 is mated with the connecting screw rod 211, and the external thread of the connecting screw rod 211 is connected with a plurality of nuts 2111, so that the seat body 220 can be increased and lengthened according to the width of the segment, and after the increase, the connecting screw rod 211 and the nut 2111 Cooperate with the limit, so that the support width of the connection base 210 can be extended by using the extension base 220, so as to adapt to the support of segments of different widths.

[0054] Further, one side of the extension seat 220 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com