Process and device for smelting copper by pulsation vortex method

A process and method for copper, which is applied in the field of pulsating cyclone copper smelting process and devices, can solve the problems of high occurrence rate of smoke and dust, low probability of collision between particles, scouring of furnace walls, etc., and achieves low occurrence rate of smoke and dust and oxygen utilization rate The effect of high, high collision probability

Active Publication Date: 2011-01-05

YANGGU XIANGGUANG COPPER

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the smelting process mainly includes flash smelting and bath smelting. Because flash smelting has the advantages of high efficiency, energy saving, and environmental protection, more than 60% of the copper in the world today is produced by the flash smelting process. Flash smelting The principle of the process is: the dry copper concentrate powder particles are completely dispersed and suspended by the distribution wind in the reaction tower, and the oxygen and the suspended concentrate particles react in the entire space of the reaction tower. This process has the following problems: First, the reaction is in The entire reaction tower space is carried out, so the heat load is large, the furnace wall is scoured seriously, and the furnace life is short; secondly, because the concentrate particles are dispersed and suspended, the probability of collision between particles is small, the reaction is incomplete, there are overoxidation and underoxidation, and the smoke and dust The incidence rate is high; the third is that the heat load is particularly large under the condition of high feeding. Generally, when the heat load exceeds 2200MJ / m3.h, the reaction tower of the flash furnace cannot bear it, so the high production capacity of a single flash furnace is limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

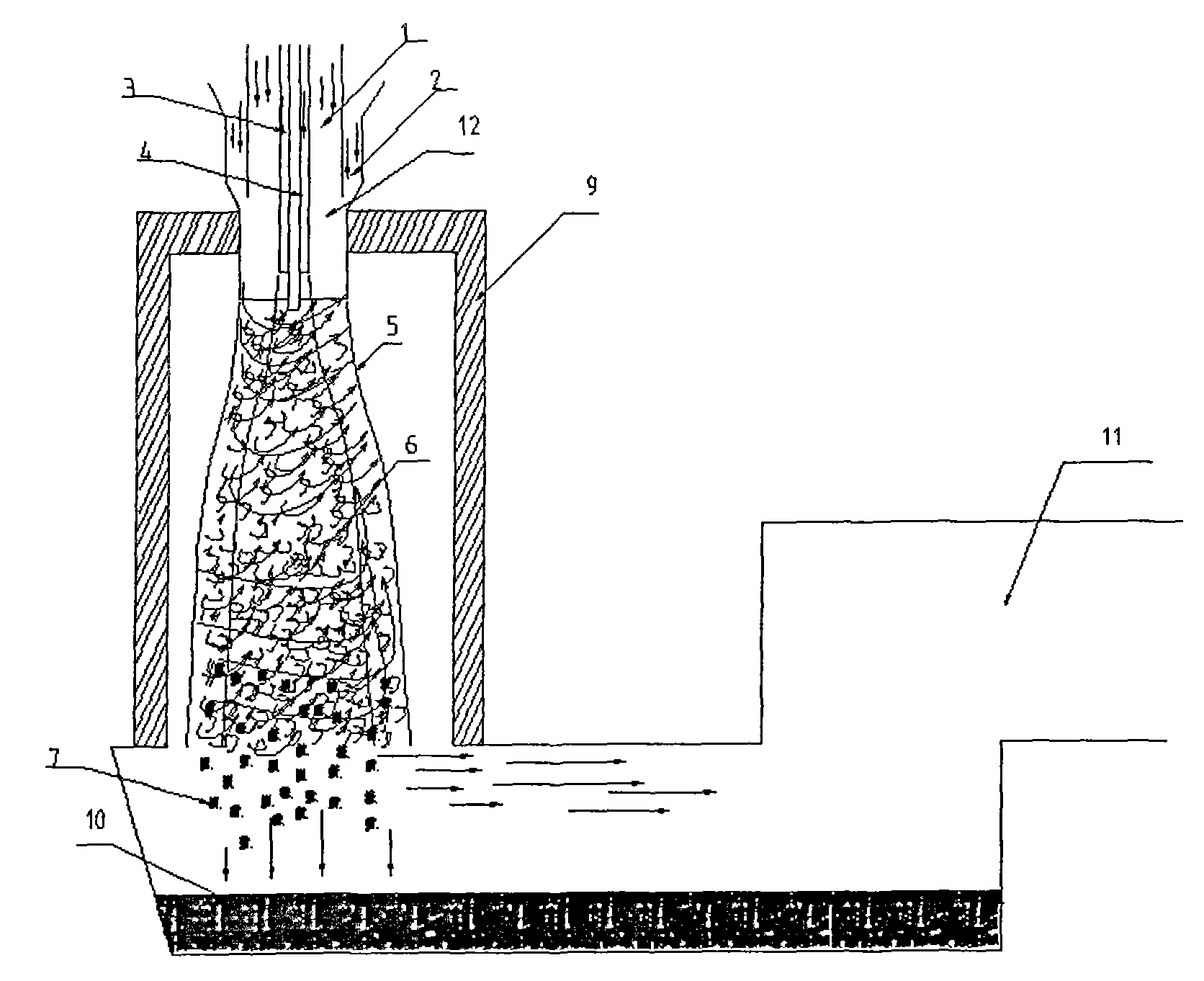

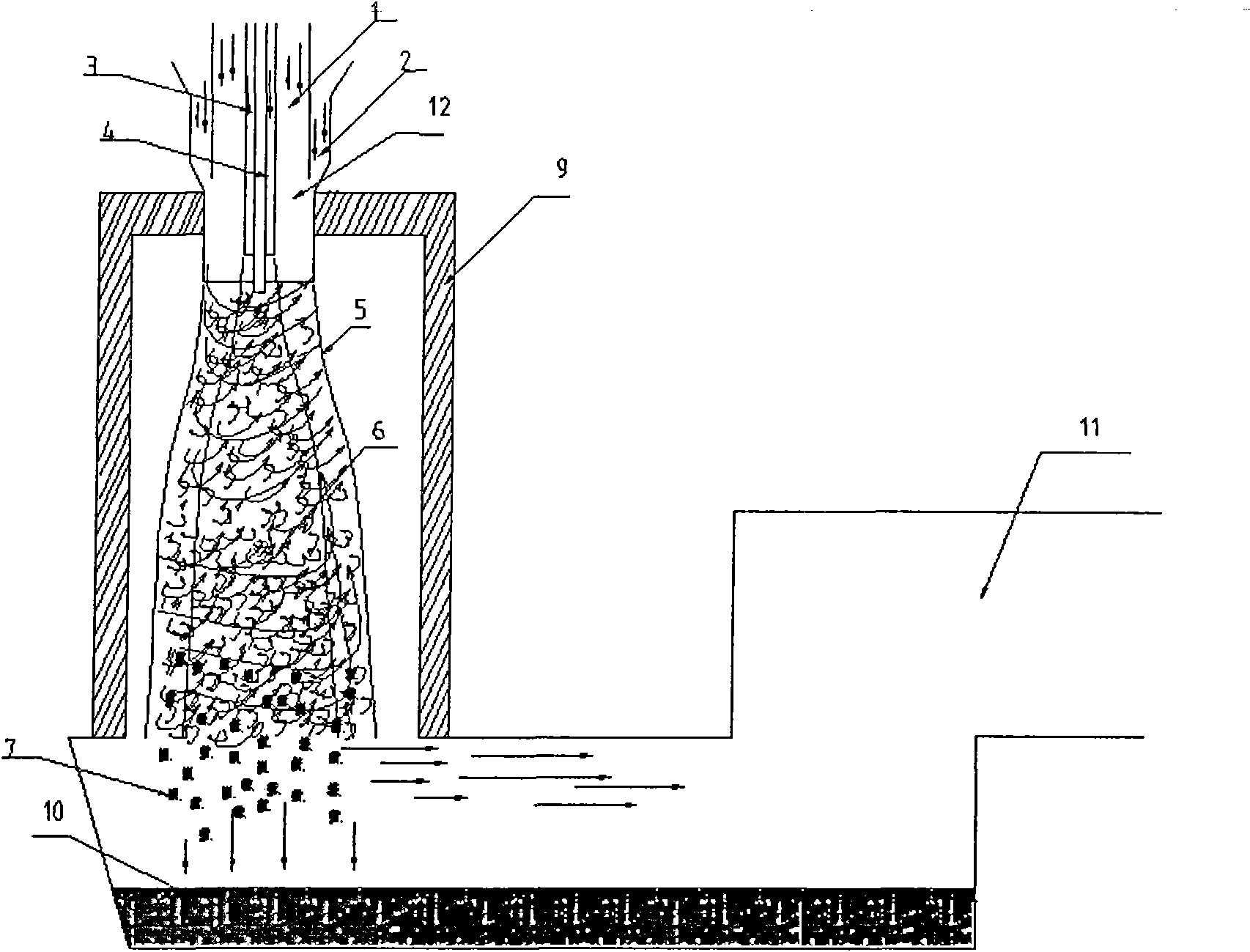

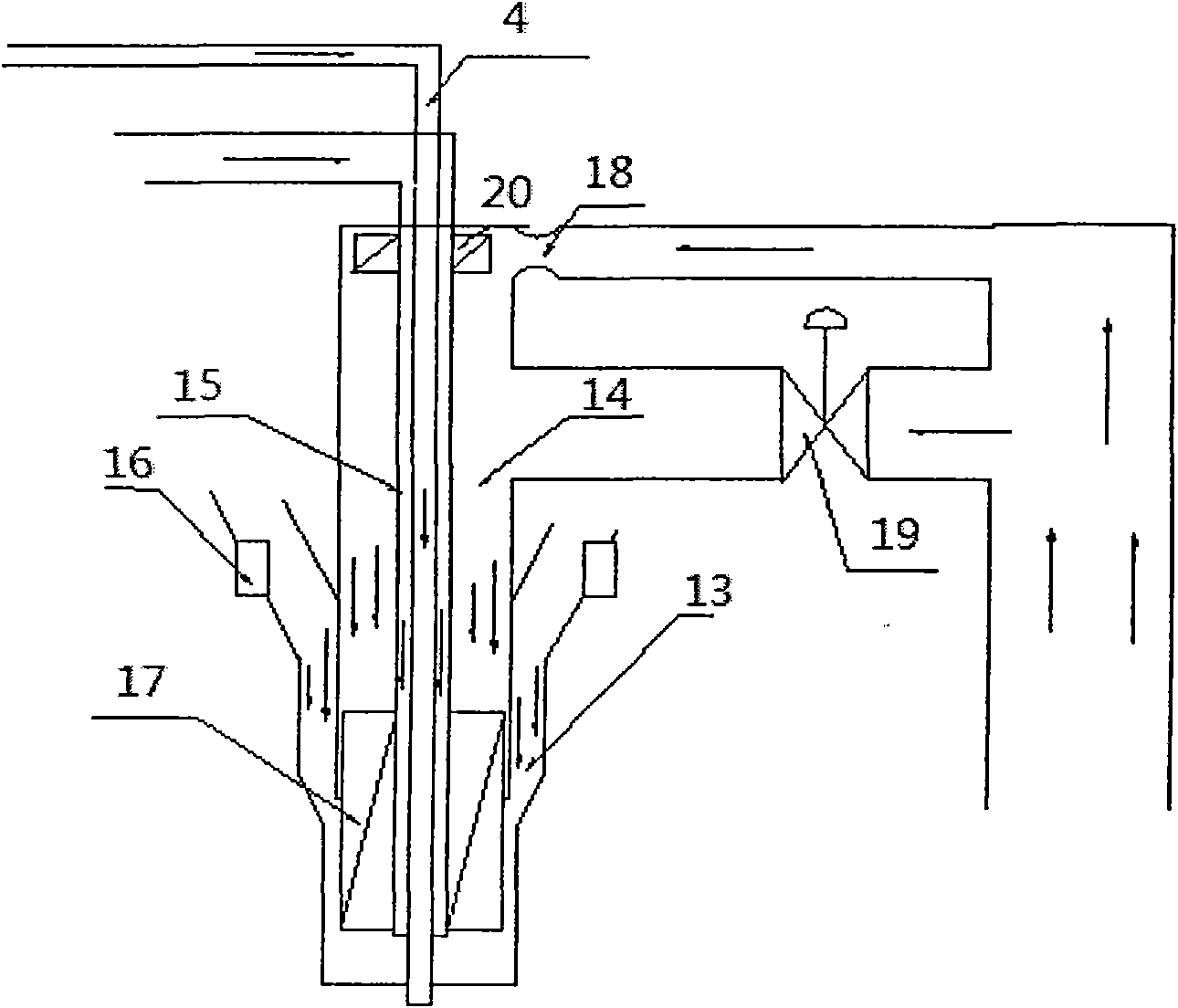

The invention relates to a process and a device for smelting copper by a pulsation vortex method. The process comprises the following steps of: mixing dry copper concentrate powder or matte powder with oxygen-enriched air, and putting the mixture in a reactor to form high-speed vortex taking an axis as a center; introducing pulsation oxygen into the center of the high-speed vortex, performing pulsation combustion to generate pulsation turbulent flow in the high-speed vortex so as to promote particles to collide with one another, then forming a pulsation vortex reaction area with a high-temperature field, a high oxygen field and a high particle field, and completing a reaction of manufacturing the matte and slag from the copper concentrate or manufacturing crude copper and slag from the matte; after the reaction, precipitating fused materials in a fusing pool at the bottom of the reactor, and then separating the matte and slag or the crude copper and slag; and sending SO2 gas fume to an acid preparation process. The process and the device have the advantages of: 1, high reaction efficiency, high oxygen utilization efficiency and low fume yield; 2, high capacity, low energy consumption, small reaction space, centralized heat energy reacted, low loss of a refractory material of a furnace body, no need of a huge metallurgical hearth and low investment cost; and 3, environmental protection and simple, convenient and reliable technological operation.

Description

Copper smelting process and device by pulsating swirling method technical field The invention relates to the metallurgical technical field of copper, nickel, lead, etc., in particular to a copper smelting process and device by a pulsating swirl method. Background technique Copper is mainly sulfide ore and oxide ore in nature, especially sulfide ore is the most widely distributed, and about 80% of copper ore exists in the form of Cu-Fe-S ore. Pyrometallurgy is usually used to extract copper from such ores. The general process is: copper sulfide ore → mining process → copper concentrate → smelting process → matte copper → blowing process → crude copper → anode furnace process → anode copper →Electrolysis process→High-purity cathode copper. At present, the smelting process mainly includes flash smelting and bath smelting. Because flash smelting has the advantages of high efficiency, energy saving, and environmental protection, more than 60% of the copper in the world today i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B15/00

Inventor 周松林刘卫东

Owner YANGGU XIANGGUANG COPPER

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com