Method for preparing immobilized enzyme by using spherical bacterial cellulose as carrier

A bacterial cellulose, immobilized enzyme technology, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve the problems of bacterial cellulose pellet immobilization enzymes, etc., Achieve the effect of good biodegradability, strong controllability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

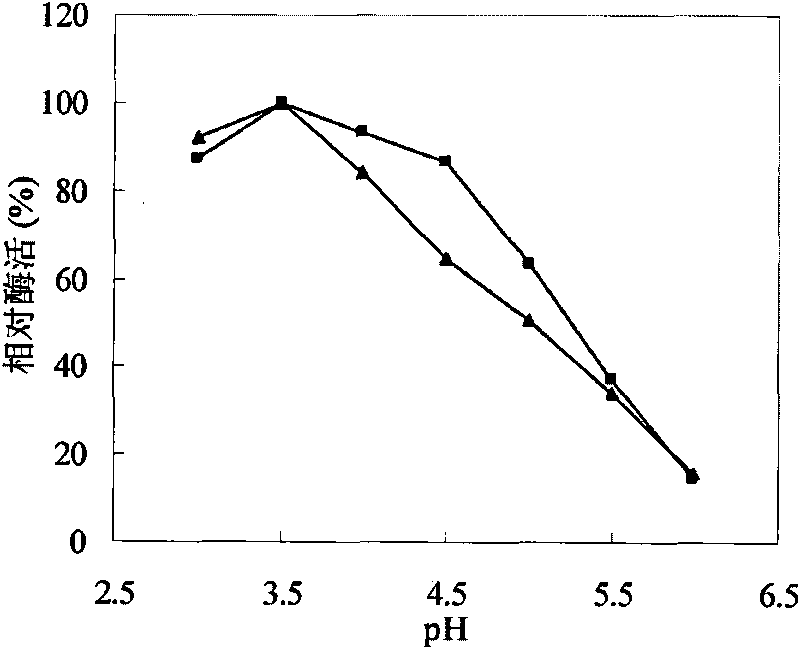

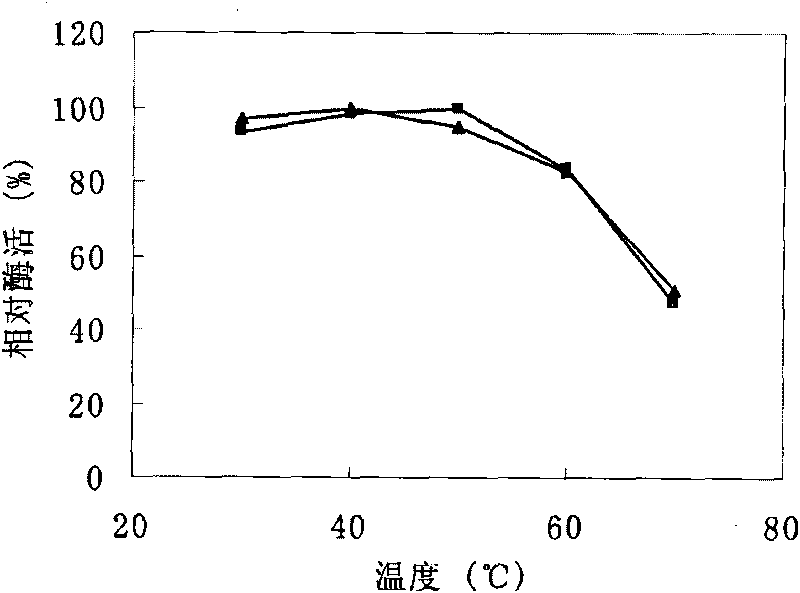

Image

Examples

Embodiment 1

[0031] Pick 1 loop of single bacterium colony to inoculate in 100mL aseptic seed culture medium from the slope of Acetobacterium aceticum, described seed culture medium comprises (mass percentage): glucose 2.0%, yeast powder 0.5%, tryptone 0.5%, Na 2 HPO 4 12H 2 O0.27%, 0.115% citric acid, pH5.0, cultured at 30°C, 130rpm for 12h. The seed solution was inserted into a 500mL Erlenmeyer flask containing 300mL sterile fermentation medium with a 6% inoculum amount. Described fermentation medium comprises (mass percentage): glucose 2.0%, yeast powder 0.5%, tryptone 0.3%, Na 2 HPO 4 12H 2O 0.27%, citric acid 0.115%, pH 5.0; 30°C, 110rpm after culturing for 72 hours, many bacterial cellulose pellets were formed in the medium. After decanting the culture medium, take out the cellulose pellets, rinse them repeatedly with deionized water to remove the culture medium and impurities on the surface of the pellets, then soak the pellets in 0.1% NaOH solution, and treat them at 80°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com