Method and device for preparing lipid bilayer membrane in situ in liquid phase

A lipid bilayer and liquid phase technology, applied in the field of preparation of lipid bilayer membranes, can solve problems such as difficult to maintain temperature, membrane damage, loss of fluidity, etc., to ensure smoothness and fluidity, strong flexibility and Application prospects, the effect of short fusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

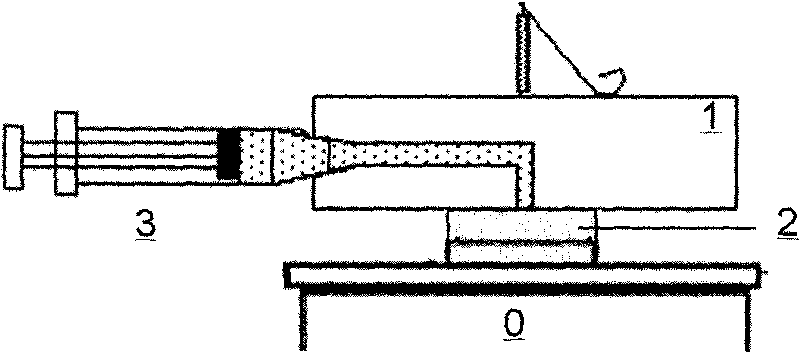

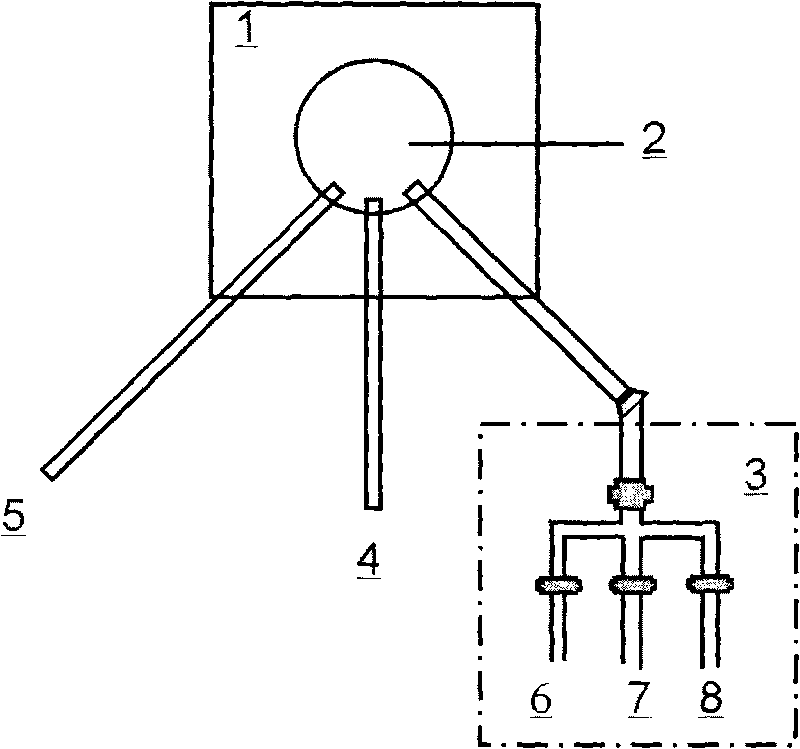

[0029] Example 1 A three-component lipid (DOPC / ESM / Chol) solid surface supported lipid film was prepared by spin coating.

[0030] The chloroform solutions of dioleoylphosphatidylcholine (DOPC), egg sphingolipid (ESM) and cholesterol (Chol) three kinds of phospholipids were mixed in a molar ratio of 2:2:1 to obtain lipid stock solution, wherein the concentration of lipid stock solution was 1.0mg (lipid) / mL (chloroform) solution. Use a spin coater to coat the mica surface with a stock solution, observe it under AFM at room temperature, and get image 3 . The parameters of the spin coater are: rotation speed 1000 rpm, spin coating time 20 s, and before AFM scanning, the sample is kept in a vacuum oven at 45°C. From image 3 It can be seen from the figure that the surface of the support film obtained by the spin coating method is not smooth, and the inside of the film is divided into several layers, which is not conducive to the observation and analysis of the morphology and i...

Embodiment 2

[0031] Example 2 The solid surface of the three-component lipid (DOPC / ESM / Chol) obtained by soaking in water and spin-coating supported the lipid film.

[0032]Soak the lipid film obtained in Example 1 above in Milli-Q water for 12 hours. After rinsing with Milli-Q water, it was placed in the AFM liquid pool and scanned at room temperature Figure 4 . It can be seen that even after the dry film is fully swollen in water, a flat surface cannot be obtained.

Embodiment 3

[0033] Example 3 A three-component lipid (DOPC / ESM / Chol) solid surface supported lipid membrane was prepared by common vesicle fusion method.

[0034] Take 2 mL of the stock solution in Example 1 and prepare it into a 1.0 mg (lipid) / mL (Milli-Q water) vesicle suspension solution. The average size of the vesicles is less than 200nm. Take 1mL of the vesicle suspension and put it on the surface of freshly peeled mica, keep it in an oven at 30°C for 4 hours, then carefully wash off the remaining solution with Milli-Q water, and rinse it 10 times repeatedly, trying to keep the surface in the water phase. The support membrane obtained after washing was placed in the AFM liquid pool for imaging, and the obtained Figure 5 . It can be seen that, compared with the supporting membranes obtained in Examples 1 and 2, the membranes prepared by the common vesicle fusion method are flat and have distinct phase boundaries. However, this method takes a long time for fusion, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com