Integrated treatment process of enhanced flocculation and bio-contact oxidation for high-salt oil-containing wastewater

A biological contact and biochemical technology, applied in the field of water treatment, can solve the problems of not being able to change the structural film on the surface of emulsion droplets, not being able to remove emulsified oil and dissolved oil in water, and the inhibition effect affecting the quality of effluent water, etc., to achieve good salt tolerance ability, strong impact load resistance, and complete degradation of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

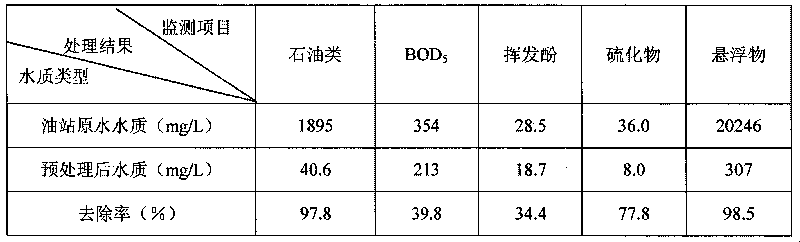

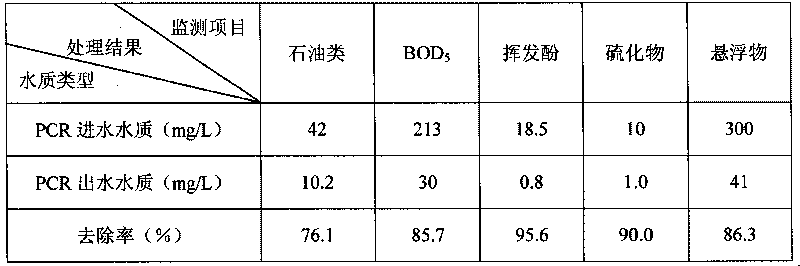

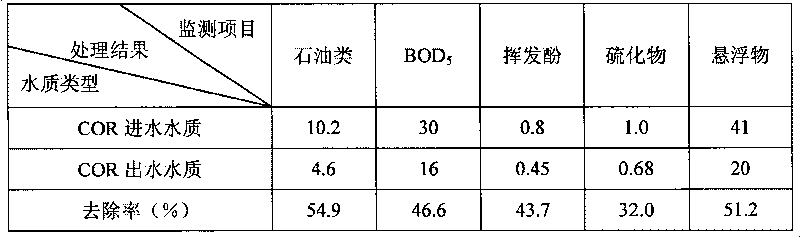

[0028] The enhanced flocculation and biological contact oxidation integrated treatment process for high-salt oily wastewater of the present invention is designed to cultivate salt-tolerant activated sludge to adapt to high-salt oily wastewater while maintaining the basic characteristics of the existing biological contact oxidation process. The treated flocculant is subjected to enhanced flocculation treatment, and biological treatment is carried out through a two-stage serial biochemical reaction system to obtain effluent with better water quality.

[0029] The main facilities used in the present invention are as follows: pool body, support, combined filler, water inlet and outlet device, aeration device, all are conventional devices. Among them, the pool body adopts a two-stage serial biochemical reactor combined with a plug-flow biological contact oxidation reactor and a fully mixed biological contact oxidation reactor. The system consists of a plug-flow biological contact ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com