Zinc oxide/titanium dioxide hybrid electrode and preparation method thereof

A technology of titanium dioxide and zinc oxide, which is applied in the field of dye-sensitized nano-thin film solar cell hybrid electrodes and its preparation, can solve problems such as the gap in conversion efficiency, and achieve the effects of reducing transmission, reducing transmission resistance, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

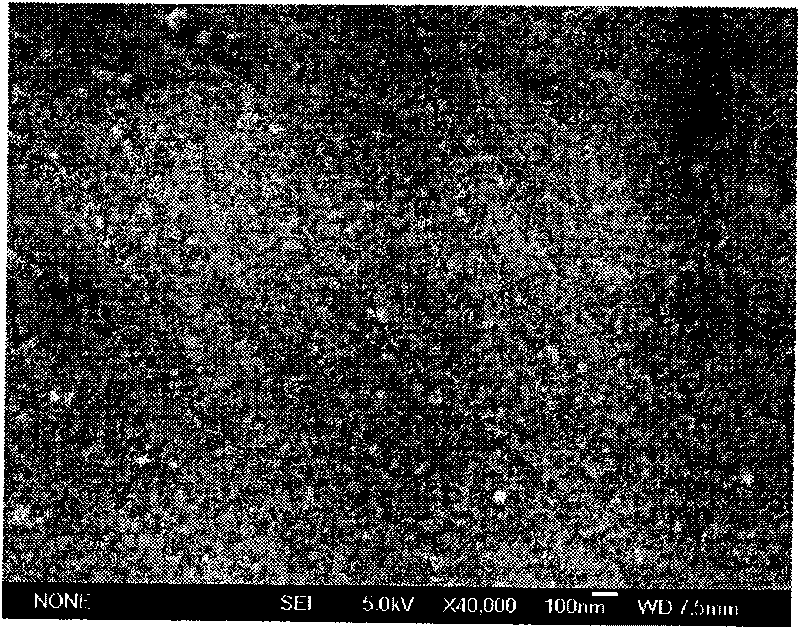

[0024] (1) Preparation of ZnO seed crystal: Line-420 magnetron sputtering apparatus, pure zinc target above 99.99%, sputtering power is 270W, O 2 The flow rate is 10 sccm, the protective gas Ar flow rate is 30 sccm, the vacuum degree during sputtering is 2.0 Pa, and the sputtering time is 1.5 h. Anneal at 500°C for 30min in air. formed as figure 1 The ZnO seeded film shown;

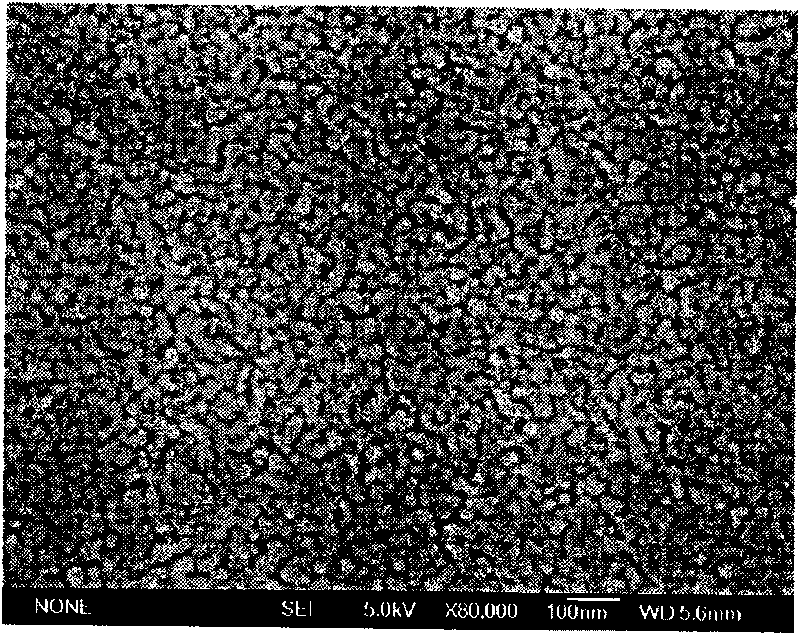

[0025] (2) Growth of ZnO nanorod arrays: Use deionized water to prepare an aqueous solution of 0.02 mol / L zinc nitrate hexahydrate, 0.02 mol / L hexamethylenetetramine and 0.01 mol / L polyethyleneimine as nanorod hydrolysis precursors Solution, vertically immerse the ZnO nano-crystal seeds prepared in step 1) into the hydrolysis precursor solution, grow in a 90°C water bath for 1.5h, take out, rinse with deionized water and ethanol, and anneal at 400°C for 30min to form figure 2 Nanorod arrays shown;

[0026] (3) Composite TiO 2 Membrane: Stir tetrabutyl titanate and absolute ethanol evenly at a volume...

Embodiment 2

[0028] (1) Preparation of ZnO seed crystals: Dissolve zinc acetate dihydrate in ethylene glycol methyl ether, mix and stir for 30min to form ZnO 2+ Sol with a concentration of 0.8mol / L. The sol was spin-coated on the cleaned FTO glass substrate at 2500r / min and calcined in air at 400°C for 20min. To form Zn by dissolving zinc acetate in ethylene glycol methyl ether 2+ The colloid with a concentration of 0.8mol / L is a sol, which is spin-coated at 2500r / min and calcined in air at 400°C for 20min to form image 3 The ZnO seeded film shown;

[0029] (2) Growth of ZnO nanorod arrays: Use deionized water to configure an aqueous solution of 0.03 mol / L of zinc nitrate hexahydrate and 0.03 mol / L of hexamethylenetetramine as the nanorod hydrolysis precursor solution, and the ZnO prepared in step 1) The nanocrystal seeds were vertically immersed in the hydrolyzed precursor solution, grown in a 95°C water bath for 1h, taken out, rinsed with deionized water and ethanol, and annealed at ...

Embodiment 3

[0032]Adjust the concentration of zinc nitrate hexahydrate and hexamethylenetetramine in Step 2 of Example 2 to 0.025mol / L, add 0.005mol / L of surfactant polyethyleneimine, change the calcination temperature to 400°C, and other conditions and steps constant.

[0033] In order to test the application of the zinc oxide / titanium dioxide hybrid electrode of the present invention in dye-sensitized solar cells, the zinc oxide / titanium dioxide hybrid electrode prepared in Example 2 was used as a photoanode, and a dye-sensitized solar cell was assembled using a general sandwich structure And carried out the photoelectric performance test. Structure: conductive substrate / hybrid electrode-dye-electrolyte / Pt electrode / conductive substrate. Wherein the Pt electrode is a Pt black electrode prepared by pyrolysis of chloroplatinic acid, the dye is N719 of 0.4mmol / L, and the redox electrolyte ratio is: 0.05mol / L I 2 , 0.1mol / L LiI, 0.4mol / L TBP, 0.3mol / L DMP II, the conductive substrate is F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com