Method for detecting junction temperature of chip of LED lamp

A technology of LED lamps and chips, applied in thermometers, measuring devices, measuring heat, etc., can solve problems such as difficult measurement of a single chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

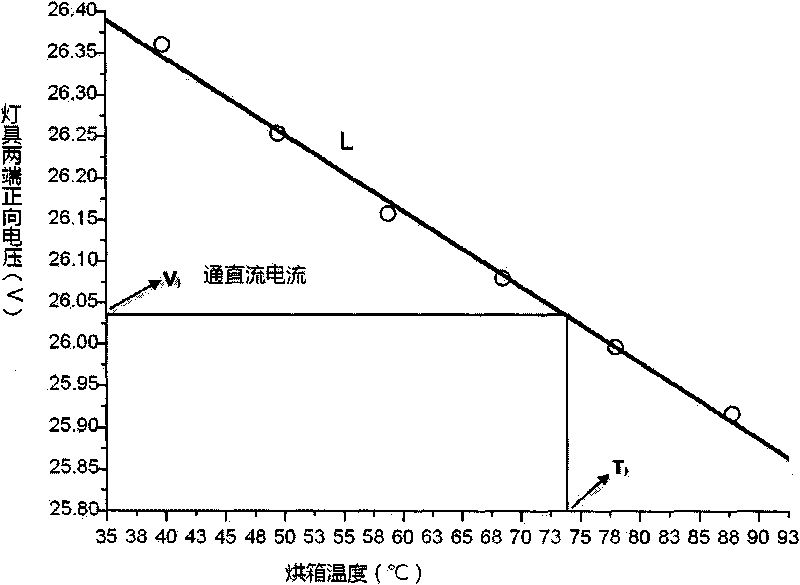

[0016] Embodiment: under the measurement room temperature, operating current is I H =2.8A, the chip junction temperature of a 75W LED lamp.

[0017] 1. The hardware system of this measurement method includes Keithley SMU2430, oven, DC power supply, PT100 platinum resistance thermometer, and Agilent 34970A inspection instrument;

[0018] 2. Paste a PT100 platinum resistor with silicone rubber on the bottom of the heat sink of the LED lamp under test, and connect the platinum resistor to the input interface of the inspection instrument;

[0019] 3. Put the tested LED lamp in the oven, power on the inspection instrument, monitor and record the temperature in the oven through the inspection instrument. Turn on the pulse power supply to make the LED lamp emit pulse light. The pulse power supply provides continuous pulse current to the lamp. The size of the lamp’s DC working current is 2.8A, the width is 550μs, and the duty cycle of the pulse current is 0.055%;

[0020] 4. Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com