Technology for reducing fluorin residue on acid cleaned surface of zirconium alloy pipe

A process method and technology of zirconium alloy tubes are applied in the direction of liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., so as to increase the safety of use, meet the requirements of use, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

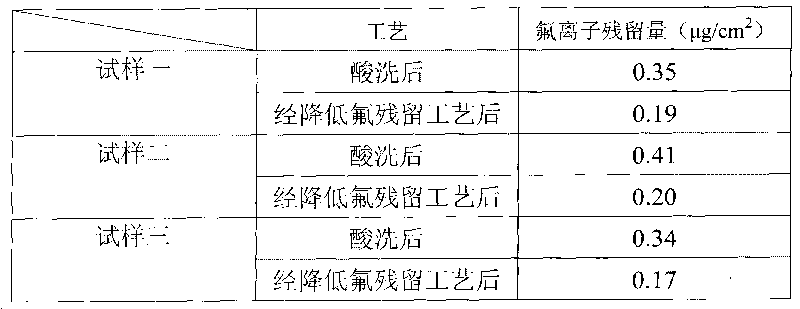

Examples

Embodiment Construction

[0021] The following is a detailed description of the specific implementation process of reducing the fluorine residue on the pickling surface of the nuclear zirconium alloy tube with a specification of Φ13×1mm. The specific implementation steps are:

[0022] a) with NH 4 HCO 3 Solution immersion, immerse the Φ13×1mm zirconium alloy tube after pickling into NH 4 HCO 3 After being in the solution, swing up and down, and the soaking time is 75 seconds, of which NH 4 HCO 3 The volume ratio of each component in the solution is: NH 4 HCO 3 : Demineralized water = 1:10;

[0023] b) Rinse with NaOH solution, and use NH 4 HCO 3 The Φ13×1mm zirconium alloy tube dipped in the solution is immersed in the prepared NaOH solution at a constant speed at an angle of about 45 degrees between its length direction and the horizontal plane, and then swings up and down. The dipping temperature is about 45 ° C ~ 55 ° C. The time is about 75 seconds, wherein the volume ratio of each compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com