Ultrahigh molecular weight polyethylene/polyvinyl chloride composite pipe and manufacture method thereof

An ultra-high molecular weight, polyvinyl chloride technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve problems that are difficult to meet sanitary technical standards, wear resistance, anti-adhesion, solvent resistance, etc. Problems such as high production costs are achieved to solve complex composite processes and low composite strength, highlighting substantive features, and simple manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

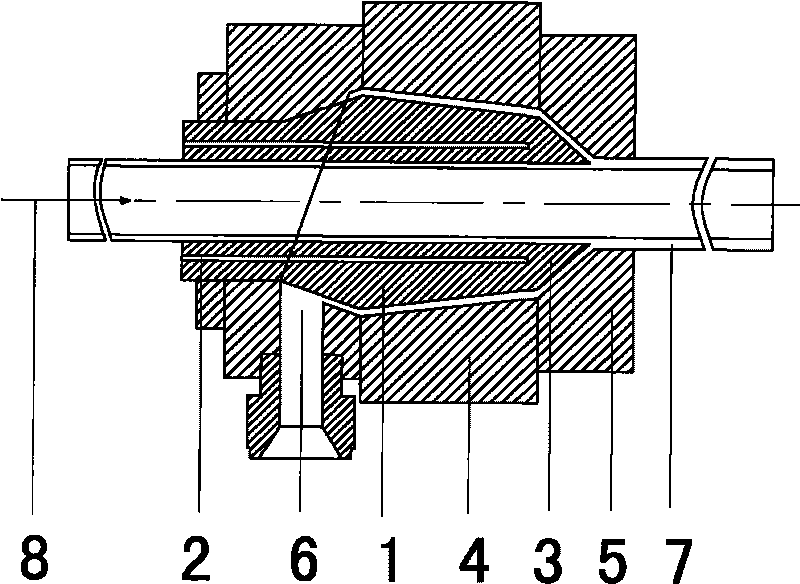

Image

Examples

Embodiment 1

[0061] Example 1 The manufacture of an ultra-high molecular weight polyethylene modified polyvinyl chloride composite pipe with an outer diameter of 110 mm and an inner diameter of 96 mm is characterized in that it comprises the following steps:

[0062] a. Manufacture of UHMWPE inner tube

[0063] ① Ingredients

[0064] Accurately weigh 50 kilograms of ultra-high molecular weight polyethylene (UHMWPE) with a viscosity-average molecular weight of 2,500,000, 2.5 kilograms of polyethylene wax with a molecular weight of 3000-5000 and mix well, for subsequent use;

[0065] ②Extrusion molding

[0066] Send the ultra-high molecular weight polyethylene and polyethylene wax mixture uniformly mixed in step ① into the screw extruder, and extrude through a pipe die. The main operating conditions are:

[0067] Cylinder temperature, ℃

[0068] District 1 120, District 2 160, District 3 150, District 4 190;

[0069] mold temperature, ℃

[0070] District 1 160, District 2 190, District ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com