Hydraulic power chuck controlled by electro-hydraulic proportional pressure valve

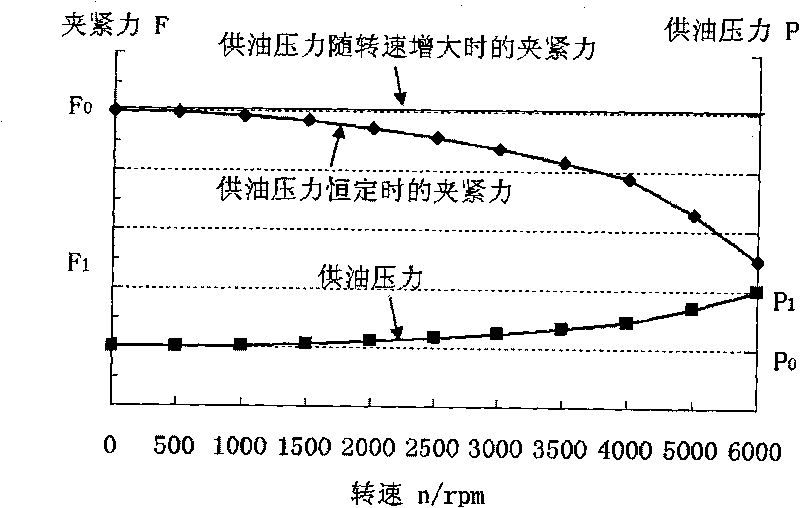

An electro-hydraulic proportional and hydraulic power technology, applied in the direction of the chuck, can solve the problems of low initial clamping force of the power chuck, damage to the surface quality of the workpiece, damage to the finished workpiece, etc., to achieve reliable clamping, meet high-speed cutting, The effect of improving the control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated by the accompanying drawings and examples.

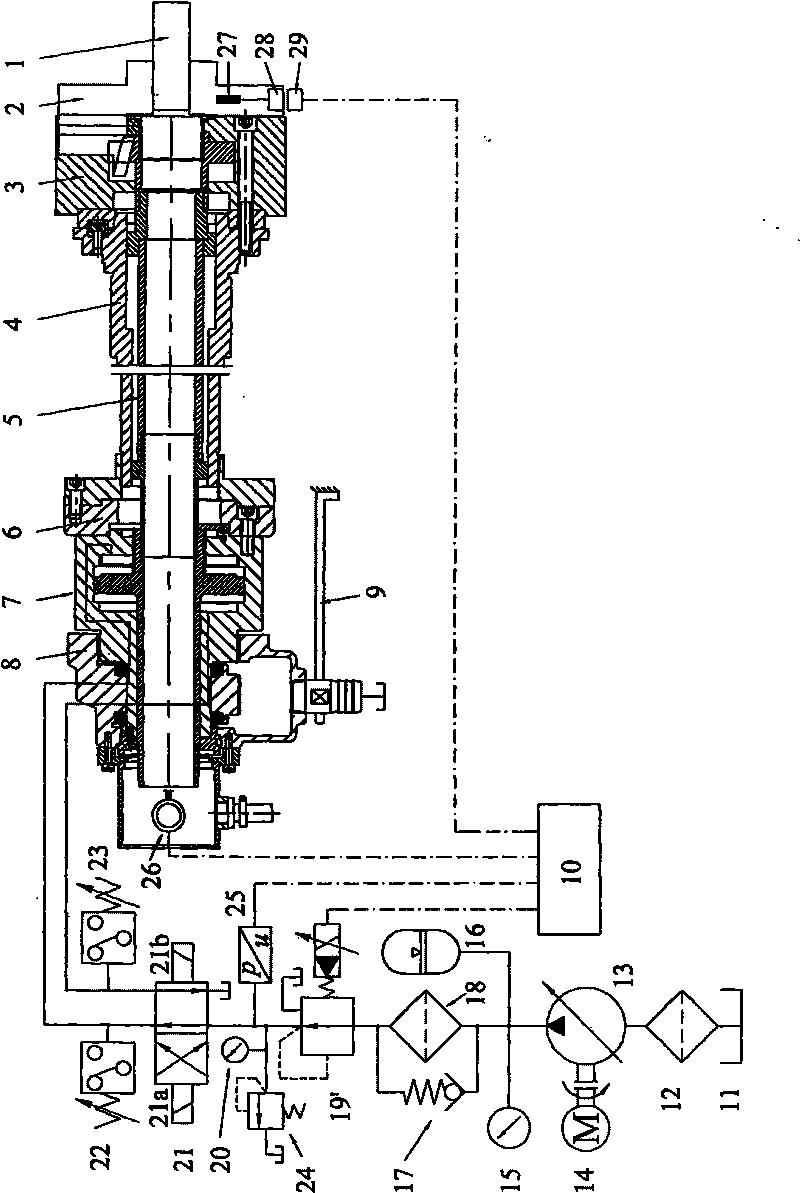

[0020] The first embodiment of the present invention is figure 1 As shown, the present invention comprises a hydraulic power chuck, a hydraulic pump station composed of an oil supply device, an oil pressure regulator, an oil supply direction control device, and an oil supply pressure monitoring device, and a signal acquisition control system; the hydraulic power chuck is composed of a power chuck The disk 3 and the rotary hydraulic cylinder 7 are composed of the power chuck 3 connected with the front end of the lathe spindle 4, the rotary hydraulic cylinder 7 is connected with the tail end of the lathe spindle 4 through the transition flange 6, and the two ends of the pull pipe 5 are respectively connected with the rotary hydraulic cylinder. The piston rod of 7 is connected to the wedge sleeve of the power chuck 3, the rotary hydraulic cylinder 7 drives the power chuck 3 to cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com