Method for coating polyethylene isolation layer on inner walls of steel pipes for ship

A technology for polyethylene isolation layer and inner wall of steel pipe, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., to save investment, maintenance and replacement costs, prevent corrosion, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

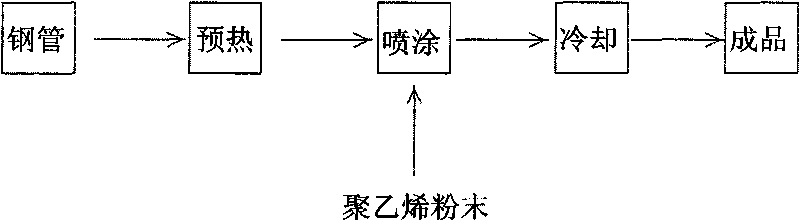

[0017] The method of the invention is completed through the preheating and spraying process of the steel pipe.

[0018] 1. Steel pipe preheating

[0019] Steel pipe preheating is carried out using a preheating kiln.

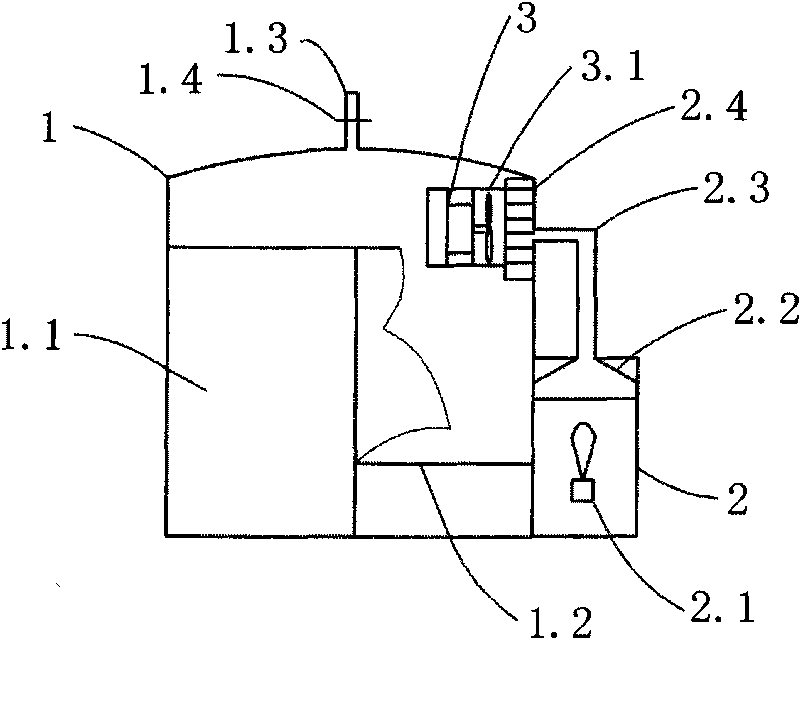

[0020] The structure of the preheating kiln is: figure 1 As shown, a kiln body with a volume inner cavity space is used as a preheating kiln 1, a kiln door 1.1 is provided on one side of the kiln, a partition 1.2 is installed on the bottom side of the preheating kiln, and a row is arranged on the upper part of the preheating kiln. Air pipe 1.3, on which exhaust valve 1.4 is installed; a heating furnace 2 is installed on one side of the preheating kiln, and a heating furnace burner 2.1 is installed in it, and a heating medium cavity 2.2 is arranged on the upper part and the side part, and the upper part The working medium conduit 2.3 is connected with the heat exchanger 2.4 arranged in the preheating kiln; a fan 3 is installed on one side of the heat exchanger, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com