Autogenous grinding and impurity removing method of thermokalite in high-purity quartz sand production

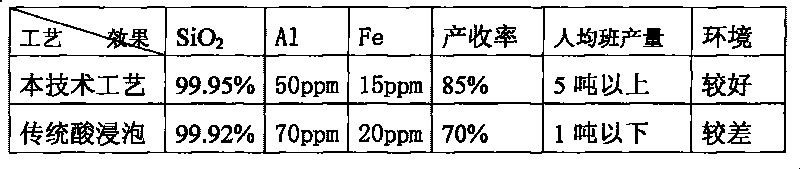

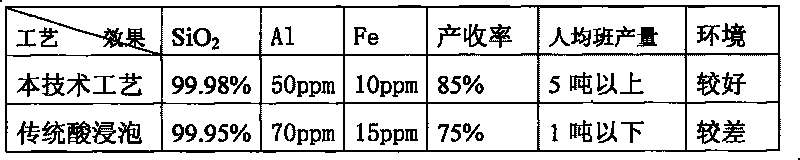

A technology of high-purity quartz sand and quartz sand, which can be used in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems of unstable quality control, waste of resources, and large amount of acid used for acid soaking. , to achieve the effect of improving resource utilization and production efficiency, eliminating the influence of human factors, and reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the hydrothermal vein quartz produced in Qianshan County, Anhui Province is used as raw material, and processed according to the following procedures:

[0024] 1. Coarse crushing: Start the jaw crusher to crush the raw quartz ore to less than 6 cm.

[0025] 2. Soaking: The coarsely crushed quartz ore is evenly fed into the autogenous mill through the feeder, and at the same time, the pre-prepared 1% NaOH solution is fed according to the stable flow rate of the liquid-solid volume ratio of 1:1.

[0026] 3. Peeling: Preheat the horizontal autogenous mill with electric heating until the temperature of the probe installed above the inner side of the discharge port reaches 90°C. Taking the air temperature measured here as a reference system, set the control temperature of the electric heating system to 90°C. (Experiments have shown that the heating temperature needs to be controlled above 40°C. The higher the temperature, the better the effect of descali...

Embodiment 2

[0032] In this embodiment, the industrial crystal imported from Brazil is used as a raw material, and is processed according to the following procedures:

[0033] 1. Start the jaw crusher to crush the raw ore to less than 3 cm.

[0034] 2. The coarsely crushed quartz ore is evenly fed into the autogenous mill through the feeder, and at the same time, the pre-prepared 0.5% NaOH solution is fed according to the stable flow rate of the liquid-solid volume ratio of 0.5:1.

[0035] 3. Preheat the horizontal autogenous mill with electric heating until the temperature of the probe installed above the inner side of the discharge port reaches 80°C. Taking the air temperature measured here as a reference system, set the control temperature of the electric heating system to 80°C. Start the autogenous mill to make the quartz ore self-grind each other and remove the impurities on the surface of the ore. Adjust the rotational speed and feeding speed of the autogenous mill to keep the displ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com