Ferrate pre-oxidation-bioactivity filter combined water treatment method

A bioactive, ferrate technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, sustainable biological treatment, etc., can solve the problem of large investment in ozone oxidation process equipment, limited ozone process application, complex maintenance and management and other problems, to achieve the effect of short contact time of empty bed, ensuring the safety of water effluent and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Example: Taking a certain surface water as the experimental source water, the water body is seriously polluted, and the typical pollutants are ammonia nitrogen 0.8mg / L, COD Mn 7.5mg / L, the smell is earthy (V).

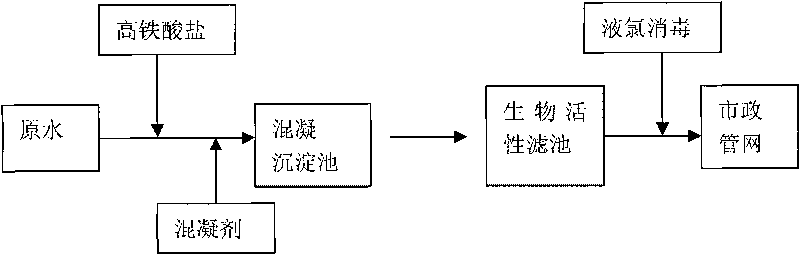

[0025] The polluted water body was treated by the combination process of ferrate preoxidation and bioactive filter.

[0026] First, add ferrate for pre-oxidation before the coagulation process, the dosage is 1.0mg / L, dosing in dry method, pre-oxidation time is 30min, after pre-oxidation, add aluminum sulfate for coagulation, coagulant The dosage is 25~30mg / L. The specific coagulation conditions are as follows: fast stirring for 1 min, with a rotation speed of 200-300 rpm; slow stirring for 10 min, with a rotation speed of 60 rpm; and a precipitation time of 30-45 min.

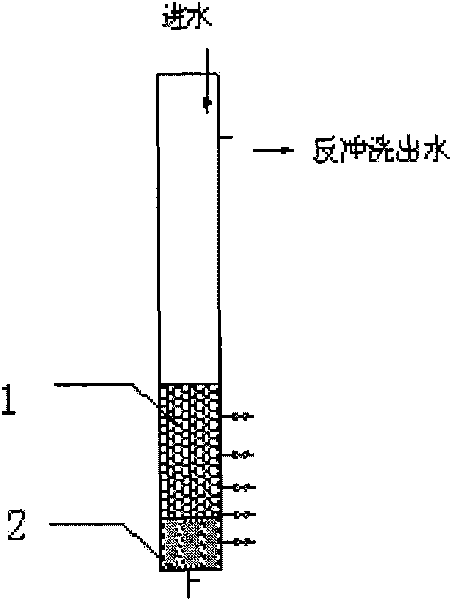

[0027] The precipitated water treated by ferrate oxidation is used as the influent of the biologically active filter. The biologically active filter is transformed from an ordinary sand filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com