Method for obtaining high-purity sulphur from Claus reactive tail-gases

A Claus tail gas, Claus reaction technology, applied in separation methods, chemical instruments and methods, sulfur preparation/purification, etc., can solve the problems of insufficient hydrogen and large hydrogen sources, and reduce process design and process. steps, cost reduction, effect of reducing the amount of additional equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

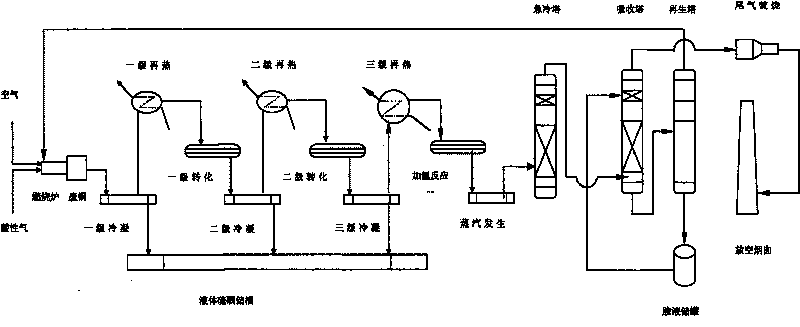

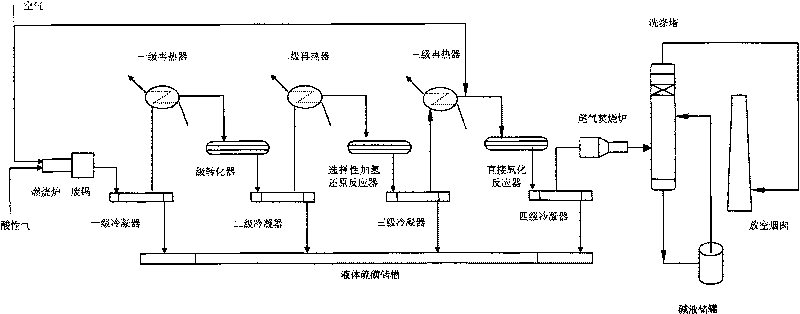

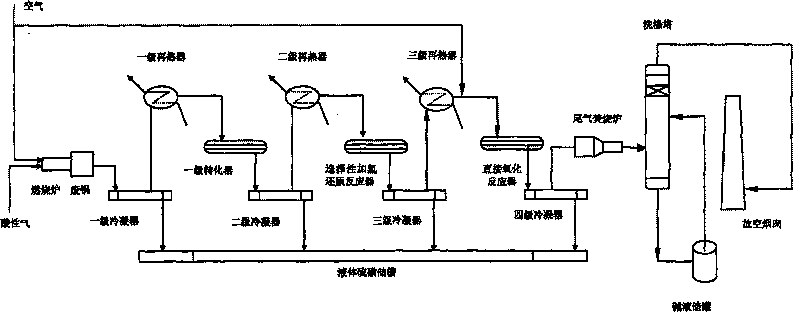

[0044] A method for obtaining high-purity sulfur from Claus reaction tail gas, comprising the following steps:

[0045] (1) Claus tail gas is preheated to 180℃~200℃ through heat exchange;

[0046] (2), the preheated gas enters the reduction reaction furnace filled with a selective reduction catalyst for the main reaction of 2H 2 +SO 2 =S+2H 2 The reduction reaction of O, wherein the selective reduction catalyst is the sulfur recovery catalyst of A999 from Shandong Schindler Chemical Group Co., Ltd.;

[0047] (3), the reacted process gas separates out liquid sulfur through the condenser;

[0048] (4) The process gas coming out of the condenser enters the adiabatic-isothermal integrated reactor filled with titanium-based catalysts for direct oxidation reaction after being re-allocated with oxygen and preheated;

[0049] (5) The gas coming out of the reactor passes through the sulfur condenser and separator to precipitate liquid sulfur, and the tail gas is incinerated, cooled...

Embodiment 2

[0051] The operating process of this embodiment is the same as that of Example 1, the difference being that in step (4) when the concentration of hydrogen sulfide in the process gas is below 1.2%, the oxidation reaction is carried out in an adiabatic reactor filled with a titanium-based catalyst .

Embodiment 3

[0053] The operation process of this embodiment is the same as that of Example 1, the difference being that in step (4) when the concentration of hydrogen sulfide in the process gas is below 1%, the oxidation reaction is carried out in an adiabatic reactor filled with a titanium-based catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com