Nonstoichiometric ratio Bi-Ag-S series thermoelectric material and preparation method

A non-stoichiometric, thermoelectric material technology, used in thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

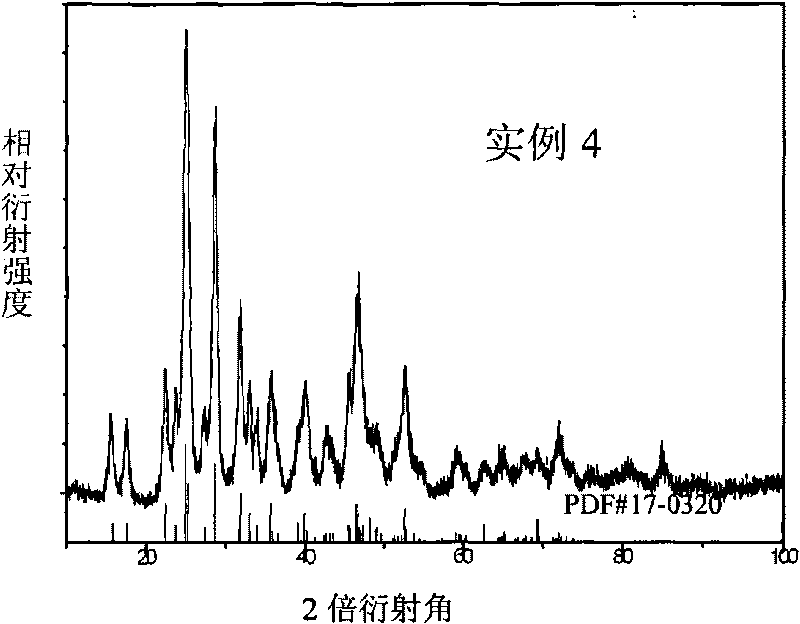

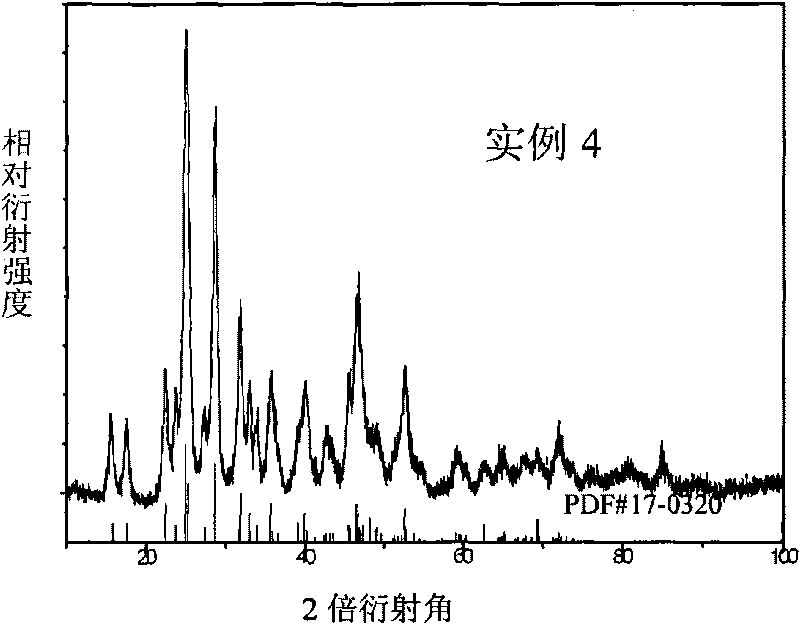

Examples

example 1

[0012] Weigh high-purity (99.99%) Bi powder, Ag powder and S powder according to the molar ratio of Bi:Ag:S 1.999:0.001:3, mix them, put them into a ball mill jar, vacuumize and fill with Ar gas, and cycle three times , make the Ar gas fill the ball mill jar, and seal the ball mill jar. Then put the ball milling jar into the ball mill and mill at 400rpm for 10 hours. After the completion, take out the ball milling jar and inject 100ml of absolute ethanol into the ball milling jar. During this process, keep the Ar gas flowing to avoid damaging the inert protective atmosphere. Wet mill at 250rpm for 30 minutes . Take out the powder and put it into a drying oven to dry at a temperature of 80°C for 2 hours. The dry powder is sintered into a block by spark plasma, the diameter of the mold is 20mm, the heating rate is 100°C / min, the temperature is 300°C, the pressure is 20Pa, and the holding time is 5min. Finally a non-stoichiometric ratio Bi with a cation deficit is obtained 1.9...

example 2

[0014] Weigh high-purity (99.99%) Bi powder, Ag powder, and S powder according to the molar ratio of Bi:Ag:S 1.99:0.01:3, mix them, put them into a ball mill jar, vacuumize and fill with Ar gas, and cycle three times , make the Ar gas fill the ball mill jar, and seal the ball mill jar. Then put the ball mill jar into the ball mill, 450rpm ball mill for 15h, take out the ball mill jar after completion, inject 100ml of absolute ethanol into the ball mill jar, during this process, keep Ar gas circulation, so as not to destroy the inert protective atmosphere, 300rpm wet mill for 1h. Take out the powder and put it into a drying oven to dry at a temperature of 80°C for 2 hours. The dried powder is sintered into a block by spark plasma, the diameter of the mold is 10mm, the heating rate is 100°C / min, the temperature is 550°C, the pressure is 60Pa and the holding time is 5min. Finally a non-stoichiometric ratio Bi with a cation deficit is obtained 1.99 AgS 3 It is a thermoelectric ...

example 3

[0016] Weigh high-purity (99.99%) Bi powder, Ag powder and S powder according to the molar ratio of Bi:Ag:S 1:1:3, mix them, put them into a ball mill jar, vacuumize and fill with Ar gas, and cycle three times , make the Ar gas fill the ball mill jar, and seal the ball mill jar. Then put the ball milling jar into the ball mill, 300rpm ball milling for 20h, take out the ball milling jar after completion, inject 100ml of absolute ethanol into the ball milling jar, during this process, keep Ar gas circulation, so as not to destroy the inert protective atmosphere, 200rpm wet milling for 3h. Take out the powder and put it into a drying oven to dry at a temperature of 80°C for 2 hours. The dried powder is sintered into a block by spark plasma, the diameter of the mold is 25mm, the heating rate is 100°C / min, the temperature is 600°C, the pressure is 40Pa, and the holding time is 5min. Finally, a non-stoichiometric BiAgS with a cation deficit is obtained 3 It is a thermoelectric mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com