Mixed crystal orientation strain silicon substrate and method for preparing same

A technology of mixed crystal orientation and strained silicon, which is used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. The effect of reducing the dislocation density and avoiding the relaxation of the lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

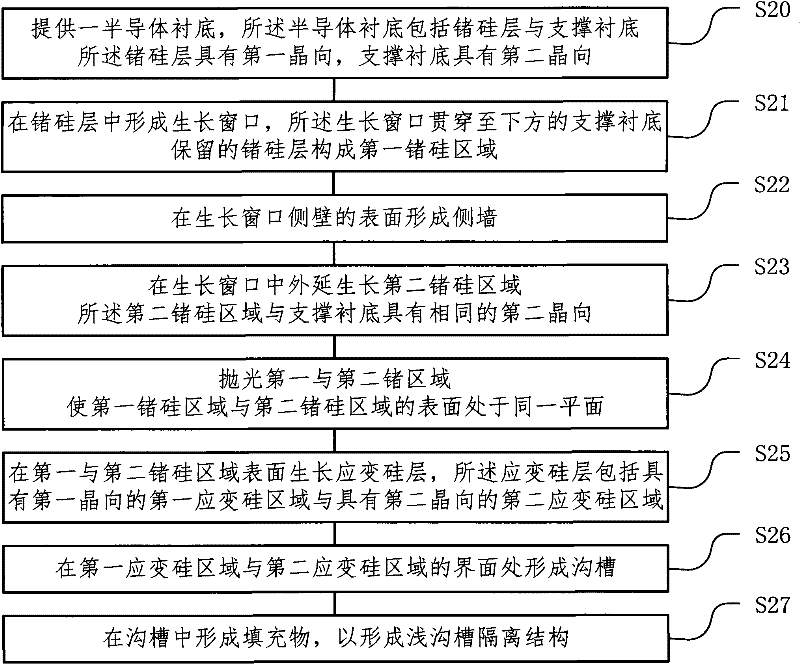

[0020] The specific implementation of the mixed crystal direction strained silicon substrate and its preparation method provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0021] Firstly, the specific implementation manner of the mixed crystal orientation strained silicon substrate of the invention will be given with reference to the accompanying drawings.

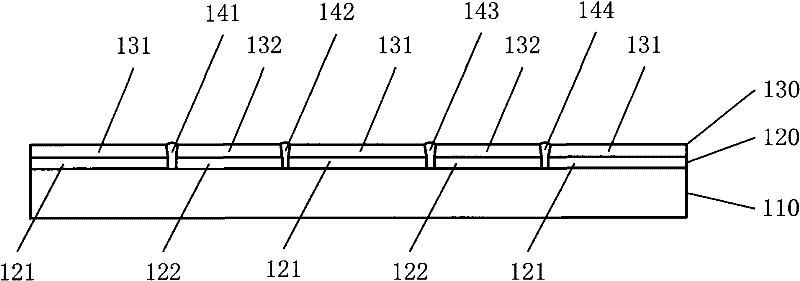

[0022] attached figure 1 Shown is a schematic structural diagram of the hybrid orientation strained silicon substrate in this specific embodiment, including: a support substrate 110 , a silicon germanium layer 120 , a strained silicon layer 130 and isolation grooves 141 - 144 .

[0023] The supporting substrate has a first crystal orientation.

[0024] The SiGe layer 120 is directly disposed on the surface of the supporting substrate, including a first SiGe region 121 and a second SiGe region 122 . The first SiGe region 121 has a first crystal orientation, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com