Polyolefin polymer having polar group, method for production thereof, and water dispersion material and mold release agent composition

一种极性基团、聚合物的技术,应用在水分散体及脱模剂组合物领域,能够解决不饱和羧酸衍生物均聚、精制花费功夫、双键向官能团改性率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

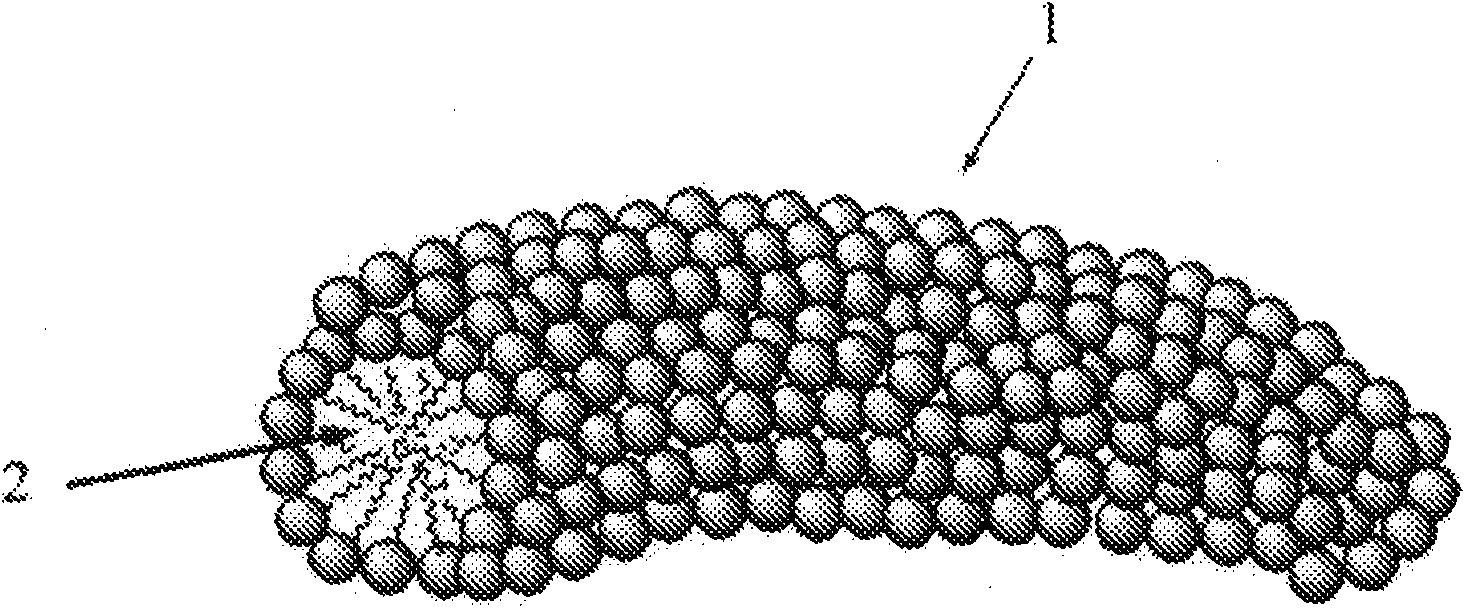

Image

Examples

Embodiment

[0252] Hereinafter, although an Example etc. demonstrate this invention more concretely, the scope of the present invention is not limited to these Examples etc.

[0253]

[0254] First, an analysis device, measurement conditions, and the like used in the analysis of the compound of this example will be described.

[0255] (1) Molecular weight, molecular weight distribution

[0256] When measuring the molecular weight of a polymer, it measures using the GPC apparatus and conditions mentioned here.

[0257] (2) 1 H-NMR spectrum

[0258] Measurement was performed by the method described herein using JNM-GSX270 manufactured by JEOL Ltd. or EX400 manufactured by JEOL Ltd.

[0259] (3) Infrared absorption spectrum

[0260] Measured using FT / IR-6100 manufactured by JASCO Corporation.

[0261] (4) FD-mass spectrometry analysis

[0262] Analysis was performed using JMS-SX102A manufactured by JEOL Ltd.

[0263] (5) Melting point (Tm)

[0264] Using DSC-60A manufactured by Shi...

Synthetic example 1

[0289] [Synthesis of Polymer (A1): Ethylene Polymer with Double Bond at One End]

Synthetic example 6

[0290] The following compound (xi) used as a catalyst was synthesized according to Synthesis Example 6 of JP-A-2003-73412, and polyethylene having a double bond at one end was synthesized according to Example 8 of the publication.

[0291] At room temperature, 1000 ml of heptane was charged into a stainless steel autoclave with an internal volume of 2000 ml sufficiently purged with nitrogen, and the temperature was raised to 150°C. Next, pressurize the inside of the autoclave to 30kg / cm with ethylene 2 G, maintain temperature. 0.5 ml (0.5 mmol) of a hexane solution (1.00 mmol / ml in terms of aluminum atoms) of MMAO (manufactured by Tosoh Finechem Co.) was injected, and then 0.5 ml of a toluene solution (0.0002 mmol / ml) of the following compound (xi) was injected (0.0001 mmol), polymerization started. After the polymerization was carried out at 150° C. for 30 minutes under an ethylene gas atmosphere, a small amount of methanol was pressurized to stop the polymerization. The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com