Deacidification agent based on sodium phytate-modified nano magnesium oxide and preparation method of deacidification agent

A technology of nano-magnesium oxide and sodium phytate, which is applied in post-processing of printing, post-processing of waste paper, printing, etc. It can solve the problems of poor dispersion and achieve the effect of mild reaction conditions, high efficiency and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

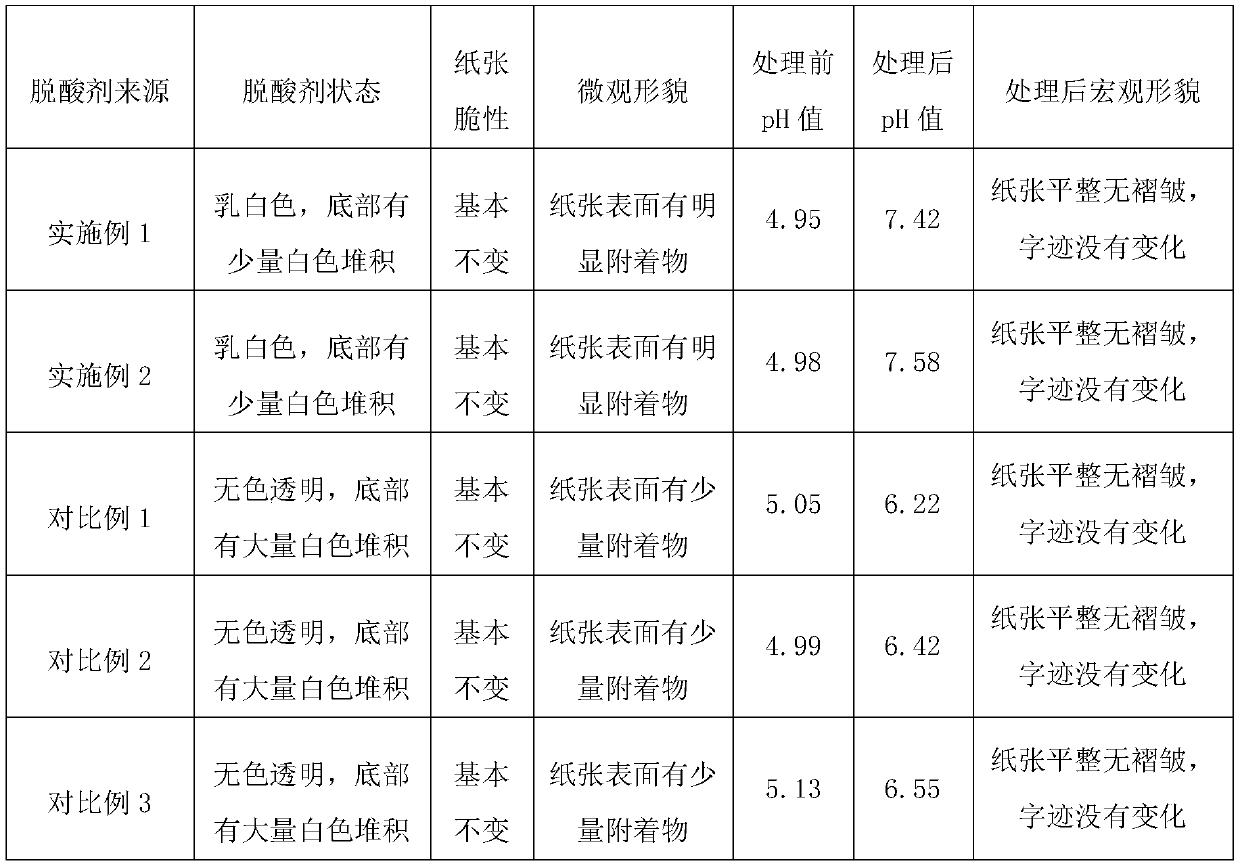

Examples

Embodiment 1

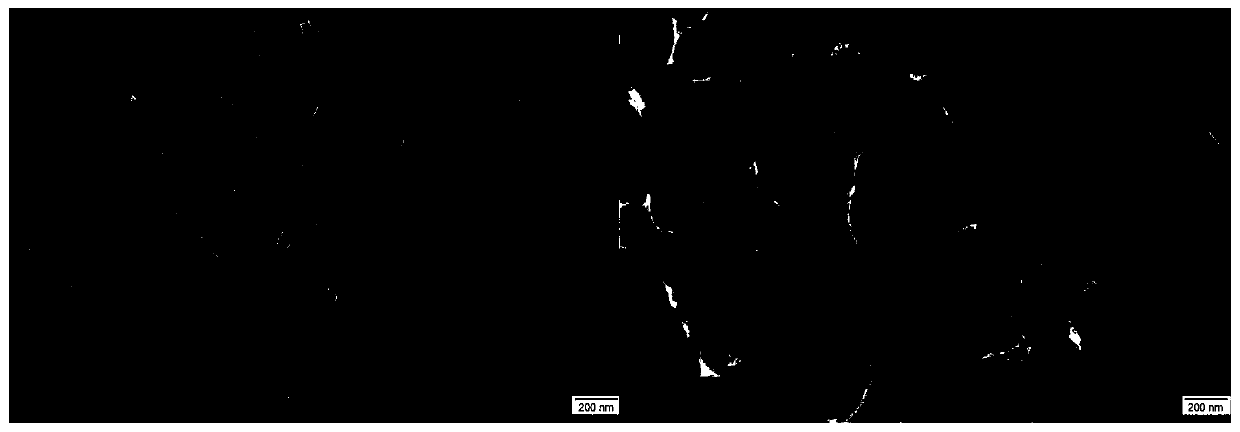

[0023] Disperse 2.5g of nano-magnesium oxide powder in 197.5g of deionized water at 70°C and stir evenly to obtain dispersion A with a concentration of 12.5g / L. Add 1 g of sodium phytate into 499 g of absolute ethanol, and stir evenly to obtain a dispersion B with a concentration of 2 g / L. The dispersion B was slowly added dropwise to the dispersion A, and the temperature of the mixed solution was maintained at 70°C for 2 hours of reaction. Suction filtration while hot after the reaction, repeated washing with 70° C. deionized water for 3 times, and then vacuum-dry the filter cake at 35° C. for 24 hours to obtain modified nano-magnesium oxide.

[0024] 1600g of perfluoroheptane and 32g of petroleum ether were mixed and stirred uniformly to obtain a mixed solvent. Add 2g of dried modified nano-magnesium oxide into the mixed solvent, transfer the resulting mixture to a homogenizer, homogenize it for 8 minutes under the condition of 8000r / min, and then sonicate it for 30 minutes...

Embodiment 2

[0026] Disperse 2g of nano-magnesium oxide powder in 248g of deionized water at 70°C and stir evenly to obtain dispersion A with a concentration of 10g / L. Add 0.8 g of sodium phytate into 199.2 g of absolute ethanol, and stir evenly to obtain dispersion B with a concentration of 4 g / L. The dispersion B was slowly added dropwise to the dispersion A, and the temperature of the mixed solution was maintained at 70°C for 2 hours of reaction. Suction filtration while hot after the reaction, repeated washing with 70° C. deionized water for 3 times, and then vacuum-dry the filter cake at 35° C. for 24 hours to obtain modified nano-magnesium oxide.

[0027] 1615g of perfluoroheptane and 35g of petroleum ether were mixed and stirred uniformly to obtain a mixed solvent. Add 1.5g of dried modified nano-magnesium oxide into the mixed solvent, transfer the obtained mixture to a homogenizer, homogenize it for 8 minutes under the condition of 8000r / min, and then sonicate it for 30 minutes, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com