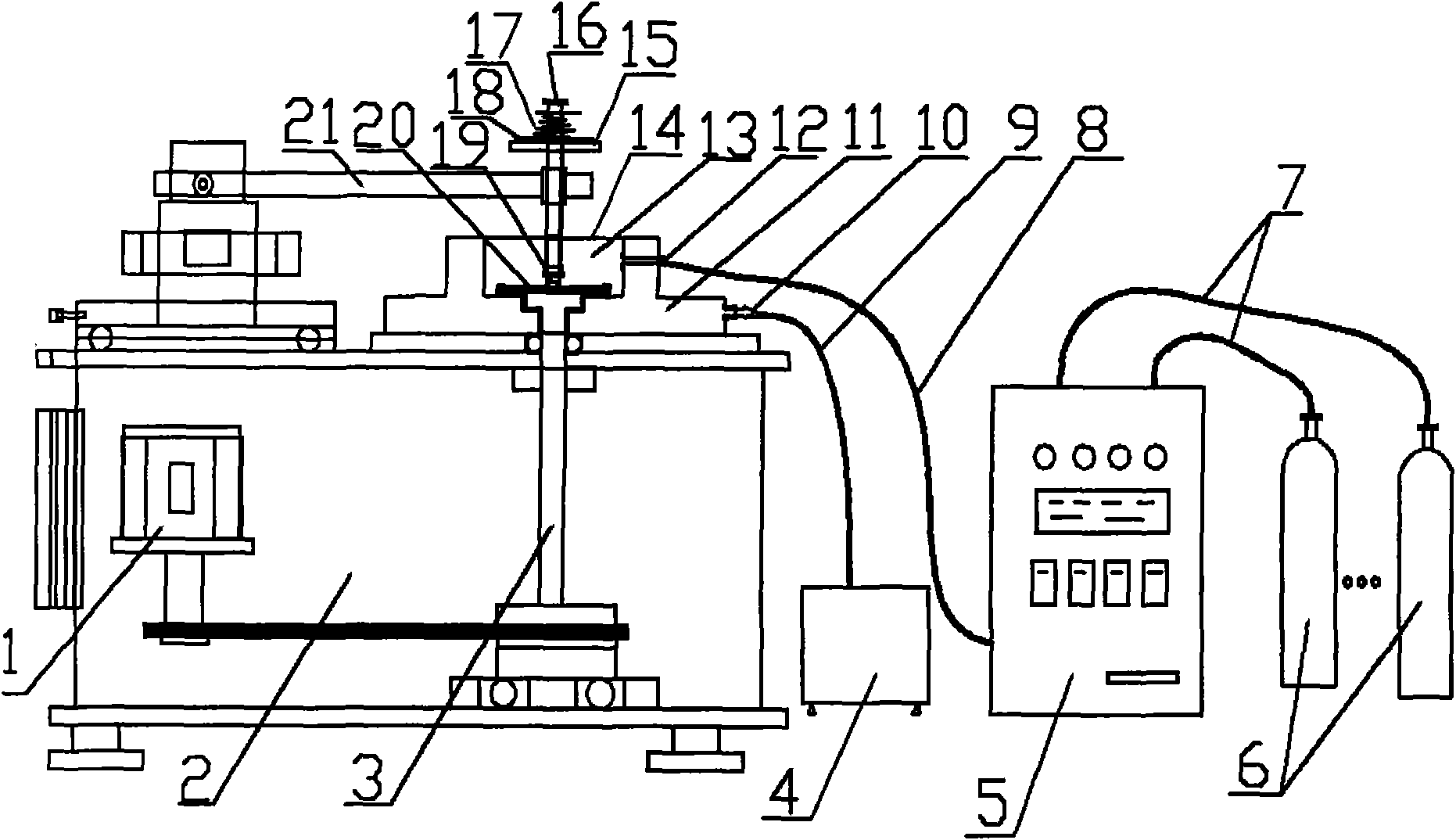

Method and device for controlling accurate ratio of various gas atmospheres of frictional wear testing machine

A friction and wear test, proportional control technology, applied in various fluid ratio control, test wear resistance and other directions, can solve the problem of affecting the proximity, affecting the accuracy of friction pairs, wrong judgment, etc., to achieve easy operation and good correlation , the effect of both control accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical scheme of the present invention is further elaborated below in the mode of embodiment:

[0011] The multi-atmosphere accurate proportional control method described in this embodiment that can meet the high-temperature atmosphere friction and wear testing machine is as follows: before the test, take out the loading rod from the environmental air chamber of the main body of the testing machine, and close the test environmental air chamber. At this time, the environmental air chamber is In a fully enclosed state, the ambient air chamber can be evacuated. Use the electric furnace wire installed around the test environment gas chamber to raise the temperature of the ambient gas chamber, and at the same time turn on the circulating water cooling system, which is driven by a small motor of the water delivery pipe. After the ambient temperature reaches a balance with the set temperature, the atmosphere with a stable flow rate that has been accurately mixed in prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com