Lithium fluoropolymer and fluoro-organic batteries

A polymer and battery technology, which can be applied to batteries with organic electrolytes, lithium batteries, batteries with solid electrolytes, etc., and can solve problems such as rate limitation and cathode material discharge rate limitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

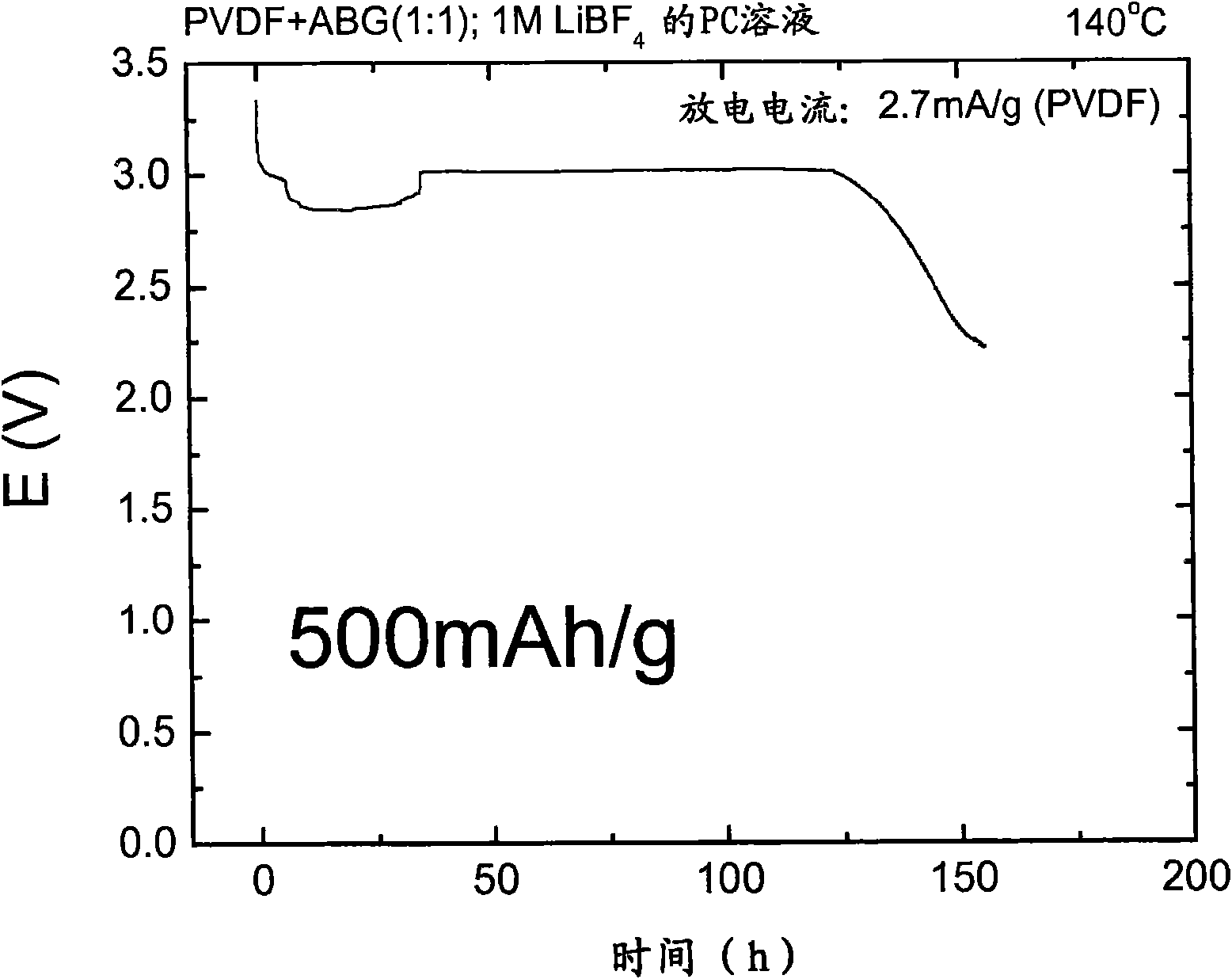

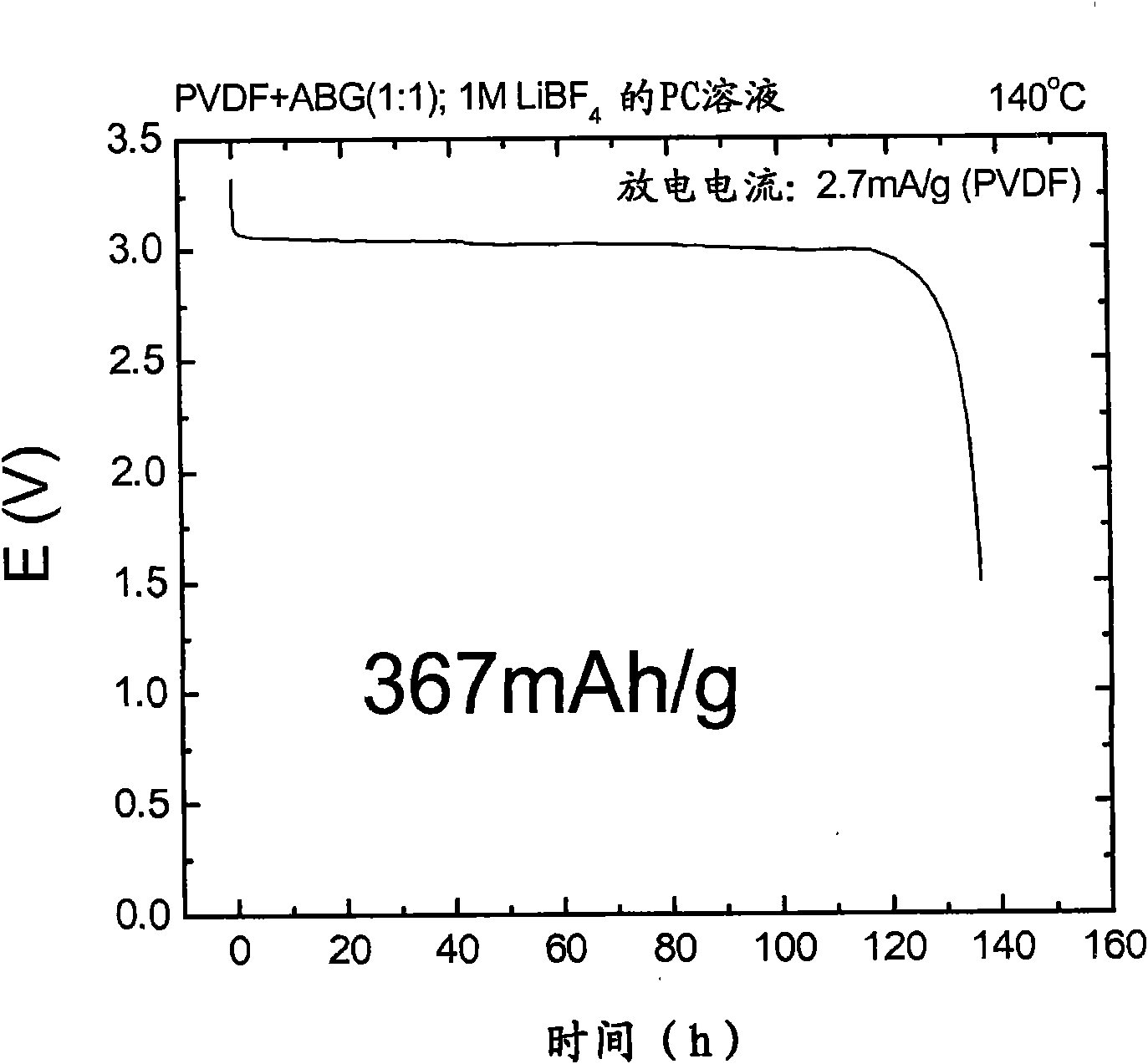

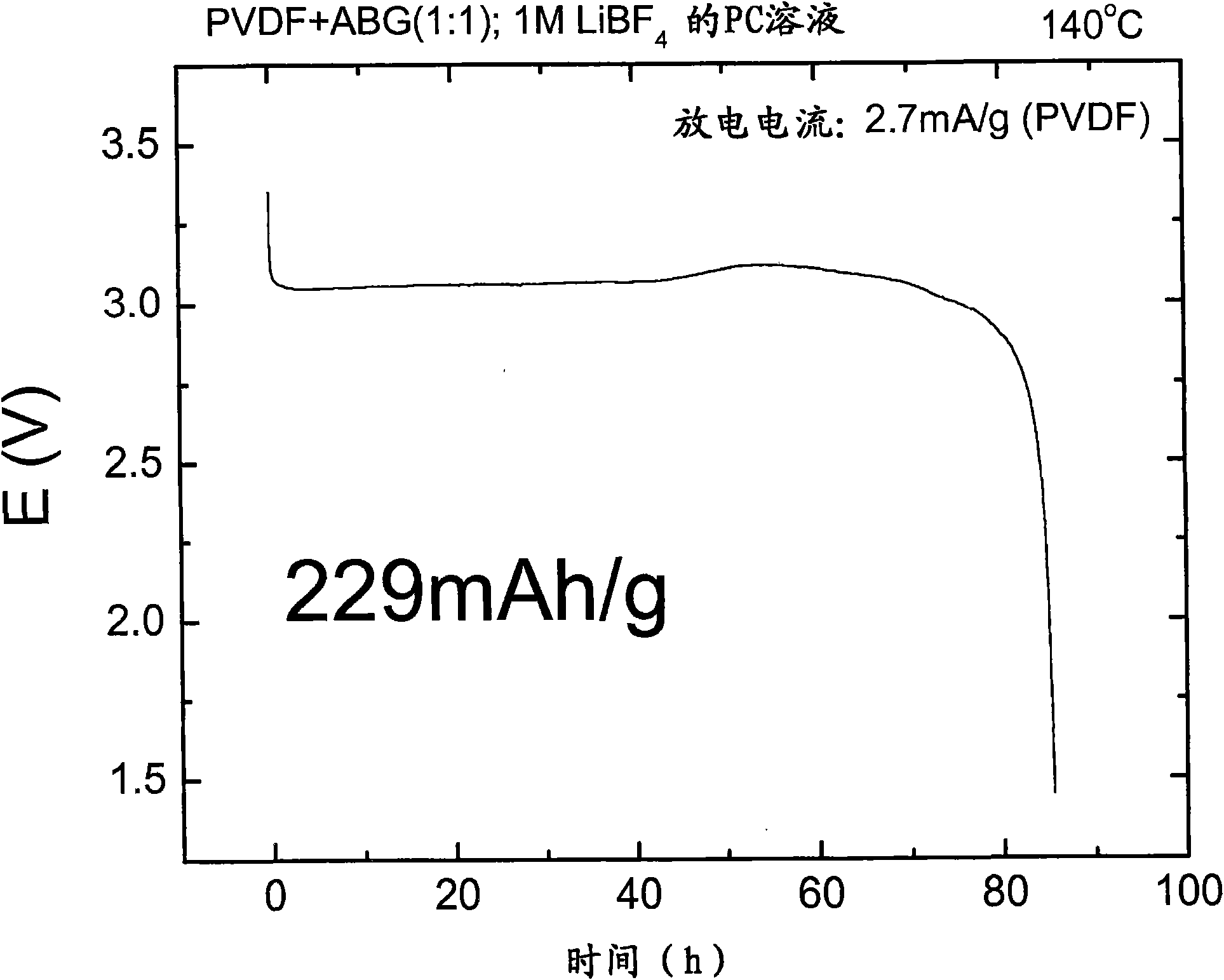

[0132] Embodiment 1: Li-PVDF battery

[0133] A battery containing a PVDF-ABG cathode and a lithium metal anode was fabricated. The PVDF particles were KYNAR 2800 (Arkema). The material is a copolymer of PVDF and hexafluoropropylene (HFP) (Arkema product literature, Kynar PVDF, Resins for Battery Manufacture, 2007). Acetylene black graphite (ABC) particles were from Superior Graphite. To prepare a conventional cathode composition, PVDF particles and acetylene black graphite (ABG) particles were mixed in a selected weight ratio, the PVDF being dissolved in acetone before mixing. The mixture is dried before pressing. The thickness is about 100-200 microns. In the test cell, a glass fiber separator (Craneglas 230, Crane and Co.) was placed between the cathode and Li anode. Electrolyte is 1M LiBF 4 propylene carbonate (PC) solution (1:1). The softening temperature of PDF is about 130-140°C.

[0134] For experiments above room temperature, the cells were placed in an oven. ...

Embodiment 2

[0140] Embodiment 2: Li-PTFE battery

[0141] A battery containing a PTFE-ABG cathode and a lithium metal anode was fabricated. The diameter of the PTFE particles is about 0.5 mm. Acetylene black graphite (ABC) particles were from Superior Graphite. To prepare a conventional cathode composition, PTFE particles and acetylene black graphite (ABG) particles were mixed in acetone in a selected weight ratio prior to mixing. The mixture is dried before pressing. The thickness is about 100-200 microns. In the test cell, a glass fiber separator (Craneglas 230, Crane and Co.) was placed between the cathode and Li anode. Electrolyte is 1M LiBF 4 PC (1:1) solution. The melting point of PTFE is about 325°C. Figure 7 Shown is the discharge curve obtained at 72°C for a cathode mixture of equal amounts of PTFE and ABG (1:1 ratio). The discharge current is 2.0μA. The discharge voltage is about 2V.

[0142] Figure 8 Shown is the discharge curve obtained at room temperature for a c...

Embodiment 3

[0143] Example 3: Li-PVDF-CF x Battery

[0144] PVDF powder (Arkema 2801) and ABG were mixed in acetone at a weight ratio of 6:4, to which was added 20% graphite CFx (x=0.74). After the acetone was evaporated in air, the resulting mixture was dried in vacuo overnight and then pressed into discs (1.6 mm in diameter and 0.3 mm thick) at a pressure setting of 80 psi. The obtained PVDF disc was coated with 1M LiBF 4 propylene carbonate (PC) solution for half an hour. Put this in a 2016-sized coin cell as the cathode. Lithium foil is the anode. Use a piece of fiberglass disk as the septum. The electrolyte is 1MLiBF 4 PC solution. Apply high temperature epoxy around the perimeter of this coin cell spacer to prevent possible leaks at high temperatures.

[0145] The battery was placed in a temperature test chamber and discharged at 10 μA as the temperature of the chamber increased from room temperature (23° C.) to 160° C. The total operating voltage increases from 2.8V at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com