Nonwoven fabric for cylindrical bag filter, process for producing the same, and cylindrical bag filter therefrom

A bag filter and manufacturing method technology, applied in membrane filters, chemical instruments and methods, filtration and separation, etc., can solve problems such as poor filtration efficiency, reduced filtration area, and can not be called, and achieve excellent capture performance , excellent shape retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

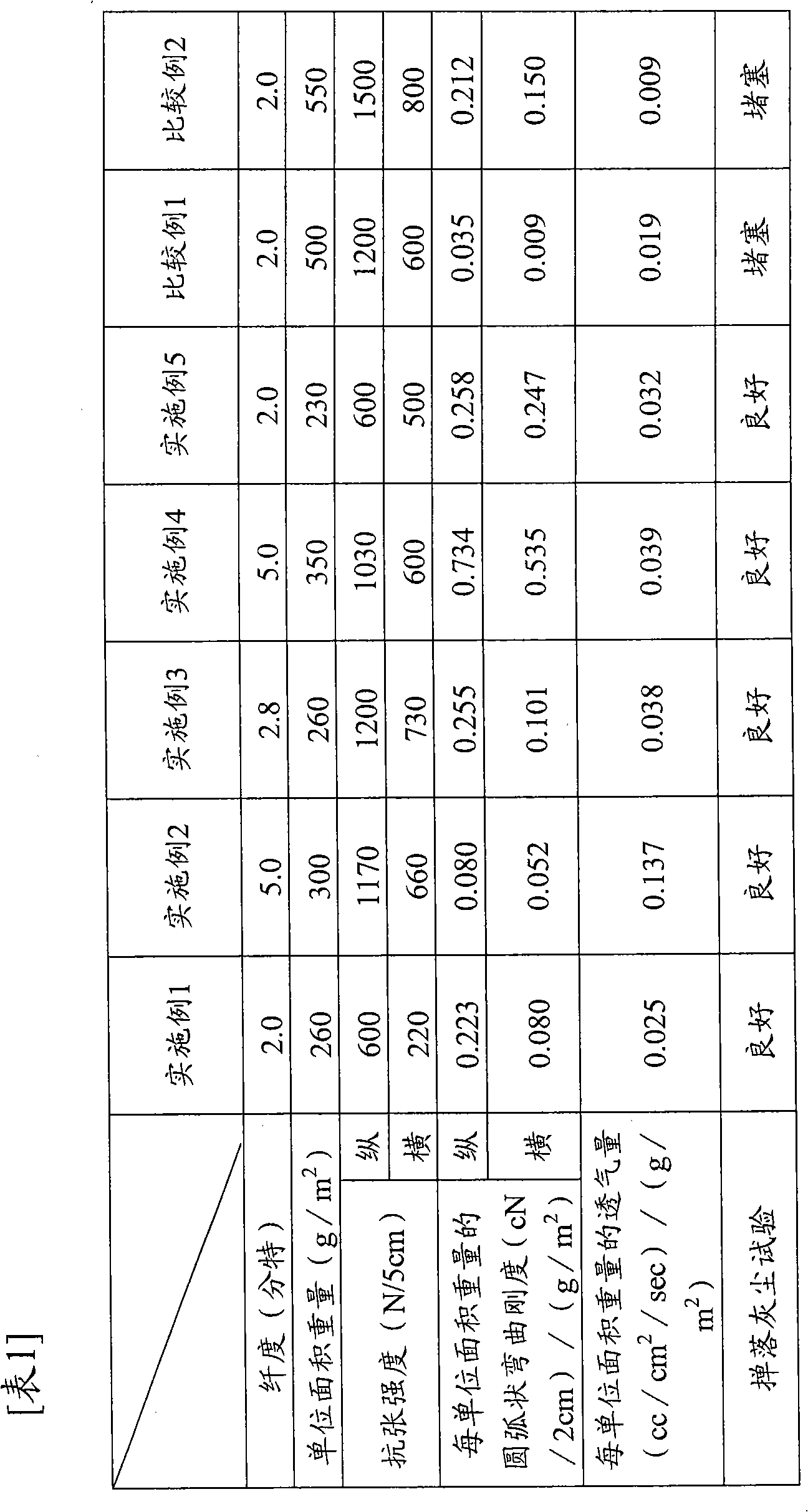

Embodiment 1

[0104] Melt polyethylene terephthalate (PET) with an intrinsic viscosity IV of 0.65 and a melting point of 260°C dried to a moisture content of 50 wtppm or less at 295°C, and spinneret at a temperature of 300°C , after being spun out from the fine hole, the single fiber with a circular cross-section shape is spun out with a suction device at a spinning speed of 4400m / min, and the fiber is opened, and it is collected as a fiber web on the moving mesh conveyor belt. . The collected fiber web was thermocompressed with an embossing roller at a temperature of 240°C and a linear pressure of 70kg / cm to obtain a fineness of 2 decitex and a weight per unit area of 260g / m 2 The embossing roller consists of a pair of upper rollers and lower rollers that form a plurality of parallel linear grooves on the surface, and it is designed as the groove of the upper roller and the lower roller The grooves intersect at a certain angle, and the convex portion of the upper roll and the convex por...

Embodiment 2

[0106] Melt polyethylene terephthalate (PET) with an intrinsic viscosity IV of 0.65 and a melting point of 260°C dried to a moisture content of 50 wtppm or less at 295°C, and spinneret at a temperature of 300°C , after being spun out from the fine hole, the single fiber with a circular cross-section shape is spun out with a suction device at a spinning speed of 4400m / min, and the fiber is opened, and it is collected as a fiber web on the moving mesh conveyor belt. . The number of punching holes on the net by acupuncture method is 80 holes / cm 2 After interlacing the fibers with the needles, the collected fiber web was thermocompressed using the following embossing rollers at a temperature of 240°C and a linear pressure of 60kg / cm to obtain a fineness of 5 decitex and a weight per unit area of 300g / m 2 In the embossing roll, an embossing roll with a woven pattern was used on the upper side, and a smooth roll without unevenness was used on the lower side, and the crimping area...

Embodiment 3

[0108] Polyethylene terephthalate (PET) dried to a moisture content of 50 wtppm or less with an intrinsic viscosity IV of 0.65, a melting point of 260°C, and an intrinsic viscosity IV of 0.66 dried to a moisture content of 50 wtppm or less , Copolyester (CO-PET) with a copolymerization rate of isophthalic acid of 11 mol% and a melting point of 230°C melts at 295°C and 280°C respectively, with polyethylene terephthalate as the core component and copolymerized Polyester is the sheath component. After the spinneret temperature is 300°C and the core: sheath = 80:20 weight ratio, it is spun from the fine hole, and the circular cross-sectional shape is spun at a spinning speed of 4300m / min with an air suction device. The single fiber is charged with a voltage of -30kV by the corona discharge method, the fiber is opened, and it is collected as a fiber web on the moving mesh conveyor belt. The collected fiber web was thermocompressed with an embossing roller at a temperature of 190°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com