Method for fermented-producing bacteria cellulose with pineapple peel juice by two-step method

A technology of bacterial cellulose and two-step method is applied in the field of production and comprehensive utilization of pineapple peels, which can solve the problems of fermented cellulose production not being carried out separately, large-scale production restrictions, pollution of ecological environment, etc., so as to shorten the static culture. Time, shorten the production time, control the effect of contamination by miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

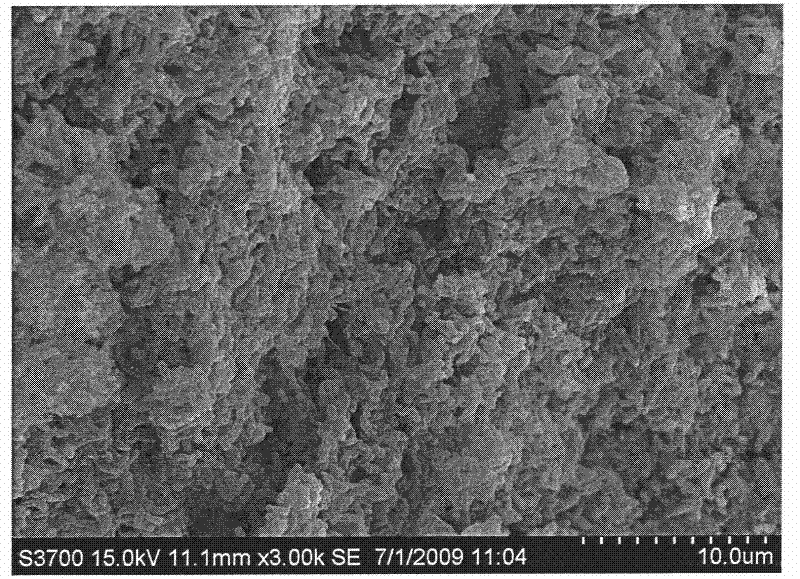

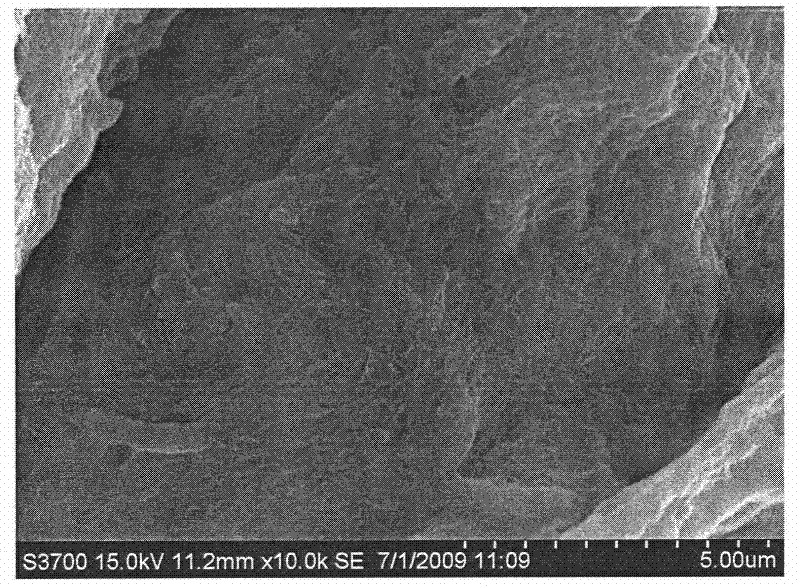

Image

Examples

Embodiment 1

[0029] A kind of method that utilizes pineapple peel juice to carry out " two-step method " fermentation to produce bacterial cellulose, comprises the steps:

[0030]The first step of activating strains: Acetobacter xylinum ATCC 23767 (Gluconacetobacter xylinum, referred to as Acetobacter xylinum) is preserved at the China Ordinary Microbiology Collection and Management Center at a ratio of 0.01% by weight, address: Courtyard No. 1, Beichen West Road, Chaoyang District, Beijing, Zip code: 100101, Tel: 86-10-64807596) strains are inserted in the seed culture medium of 100ml, at 25 DEG C, cultivate 10h in 150rpm, make mother starter; the formula of described seed culture medium is: peptone 20g, 980g of coconut water, stirred and dissolved evenly, adjusted the pH to 4.5 with acetic acid, sterilized with 0.10MPa for 15min, cooled to 25°C for later use.

[0031] The second step is a large number of bacterial proliferation cultures: the mother starter is inserted into the working st...

Embodiment 2

[0035] A kind of method that utilizes pineapple peel juice to carry out " two-step method " fermentation to produce bacterial cellulose, comprises the steps:

[0036] The first step of activating strains: Acetobacter xylinum ATCC 23767 (Gluconacetobacter xylinum, referred to as Acetobacter xylinum) in a ratio of 0.50% by weight, is preserved by China Ordinary Microorganisms Collection and Management Center, address: Courtyard No. 1, Beichen West Road, Chaoyang District, Beijing, Zip code: 100101, Tel: 86-10-64807596) the strains are inserted into 200ml of seed culture medium, cultivated at 22°C and 100rpm for 8h to make mother starter; by weight fraction, the seed culture medium formula For: peptone 5g, coconut water 995g, stir and dissolve evenly, adjust the pH to 5.5 with acetic acid, sterilize with 0.08MPa for 20min, cool to 22°C for later use.

[0037] The second step is a large number of bacterial proliferation cultures: with a volume ratio of 4:100, insert the mother sta...

Embodiment 3

[0041] A kind of method that utilizes pineapple peel juice to carry out " two-step method " fermentation to produce bacterial cellulose, comprises the steps:

[0042] The first step of activating strains: Acetobacter xylinum ATCC 23767 (Gluconacetobacter xylinum, referred to as Acetobacter xylinum) in a ratio of 0.25% by weight, is preserved by the China Ordinary Microorganisms Collection Management Center, address: Courtyard No. 1, Beichen West Road, Chaoyang District, Beijing, Zip code: 100101, Tel: 86-10-64807596) strains are inserted in 150ml seed culture medium, at 28 ℃, cultivate 12h in 200rpm, make mother starter; by weight fraction, described seed culture medium formula It is: 40g of peptone, 960g of coconut water, stir and dissolve evenly, adjust the pH to 5.0 with acetic acid, sterilize with 0.09MPa for 18min, cool to 28°C for later use. The second step is a large number of bacterial proliferation culture: the mother starter is inserted into the working starter cultu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com