Method for preparing coumaphos by aqueous phase method

A phosphatophos, water-phase technology, applied in chemical instruments and methods, chemicals for biological control, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of poor production safety, high reaction temperature, time It can reduce the production cost, reduce the reaction temperature and shorten the reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

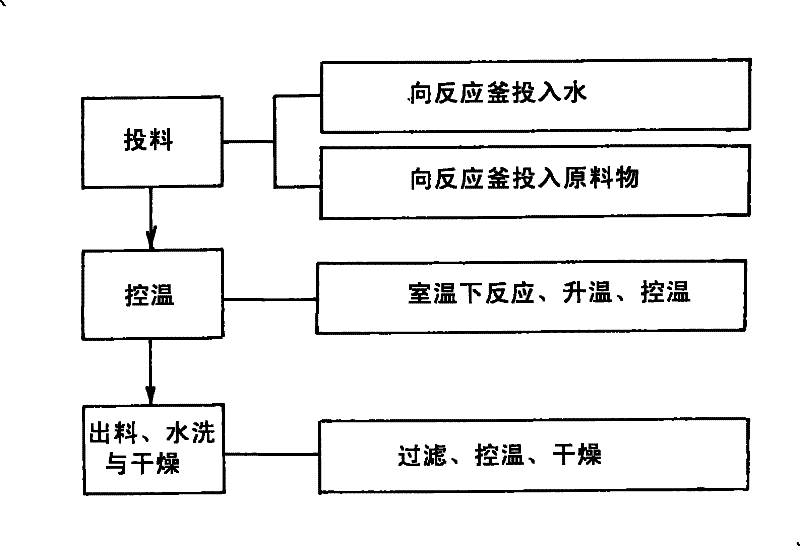

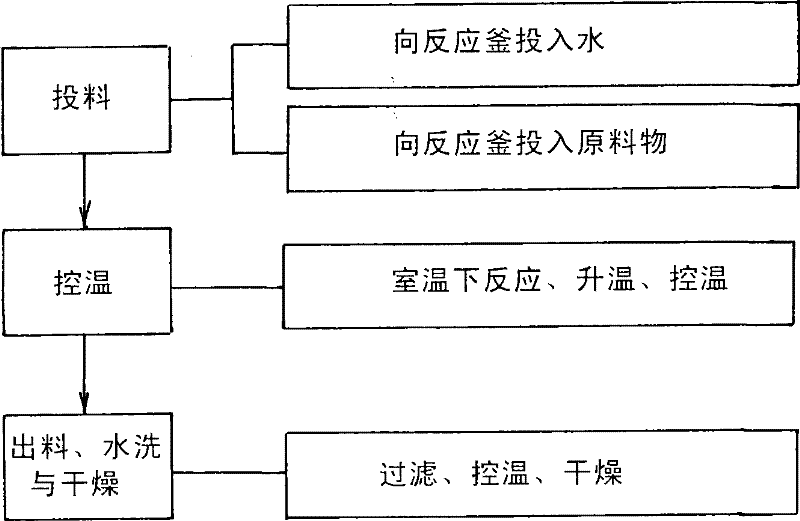

Image

Examples

Embodiment 1

[0022] (1) Feeding intake: 300 kilograms of water are dropped into 500 liters of reactors earlier, start agitator, then throw 36 kilograms of potassium carbonate, 45 kilograms of 3-chloro-4-methyl-7 hydroxycoumarin, phase transfer catalyst 1, 2 kg of 4-dimethylaminopyridine, add 40-45 kg of ethyl chloride.

[0023] (2) Temperature control: After feeding, time the reaction at room temperature for 1 hour. When the temperature was raised to 60° C., the reaction was carried out for 30 minutes, and the material was discharged.

[0024] (3) Discharging, washing and drying: put the material into the vacuum filter, filter out the waste water, wash the muscarinic acid with water until it is neutral, and then send it to the drying room to control the temperature at 75-80°C for drying.

Embodiment 2

[0026] (1) Feeding: Pour 300 kg of water into the reactor, start the agitator and add 36 kg of potassium carbonate, and then add 3-chloro-4-methyl-7 hydroxyarcohol after the potassium carbonate is dissolved (about 5 to 10 minutes). 45 kg of bean element, open the heating valve of the reaction kettle, add 3 kg of triethylamine when the temperature of the liquid in the kettle rises to 40~45°C, and then put 40~45 kg of ethyl chloride that has been weighed in advance and put into the metering tank. into the reactor.

[0027] (2) Temperature control: After the addition of chloride, when the temperature of the liquid in the tank rises to 70°C, start timing and control the temperature at 70-73°C for 2 hours, then open the cooling water valve to cool down, and wait for the liquid temperature in the tank to drop When the temperature reaches about 55°C, the reaction ends and the material is discharged.

[0028] (3) Discharging, washing and drying: put the material into the vacuum filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com