Insulating tube type busbar and manufacturing method thereof

A processing method and technology of insulating tubes, applied in the direction of insulated cables, insulated conductors, non-insulated conductors, etc., can solve the problems of reduced current-carrying capacity and cracking of ribs, achieve the reduction of outer diameter, facilitate bending and other processing, and improve current-carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

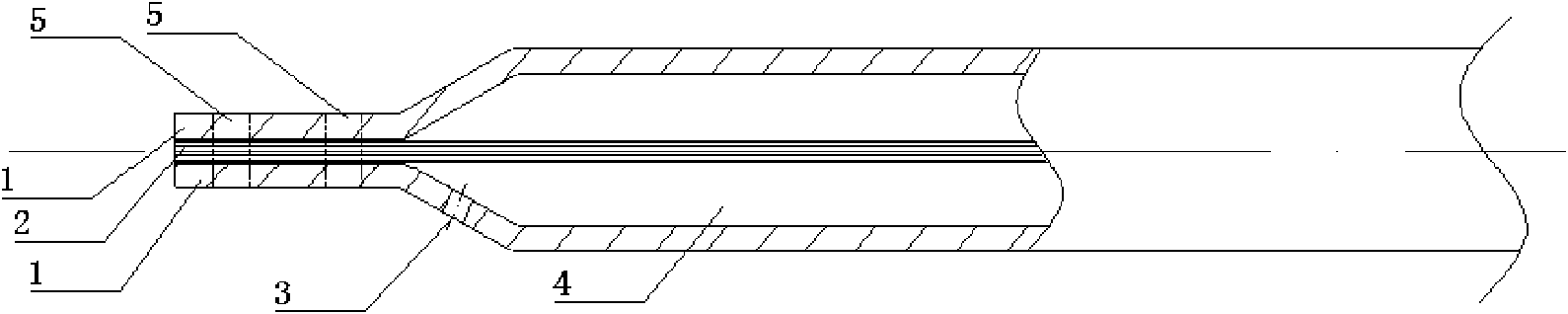

[0028] As shown in Figure 1, the insulating tubular busbar with a current of 4000A and the processing method for inserting wires inside it

[0029] The insulated tubular busbar with a current of 4000A includes: insulated tubular busbar conductor 1, wire 2, heat dissipation hole 3, heat dissipation space in the tube 4 and end plate opening 5, wherein: the insulated tubular busbar conductor 1 is located on the outermost layer, and the insulation A plurality of wires 2 are arranged inside the tube-shaped bus conductor 1 , and cooling holes 3 are provided at the end of the insulated tube-shaped bus conductor 1 .

[0030] The insulated tubular busbar conductor 1 is specifically a copper tube with an outer diameter of 80 mm and an inner diameter of 60 mm, and the copper content of the copper tube is >99.4%;

[0031] The wire 2 consists of 300 pieces of 2mm 2 Composed of tinned red copper wire, the end flat pressing effect is shown in Figure 1 side view;

[0032] The cooling hole 3...

Embodiment 2

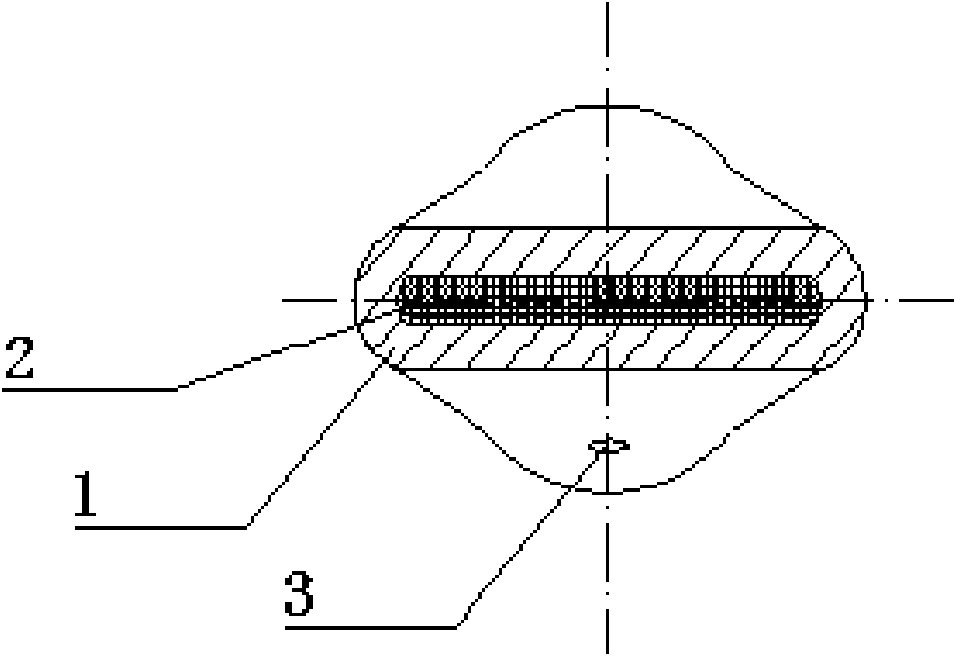

[0045] As shown in Figure 2, the insulating tubular busbar with a current of 4000A and the processing method of the hollow conductive tube inserted therein,

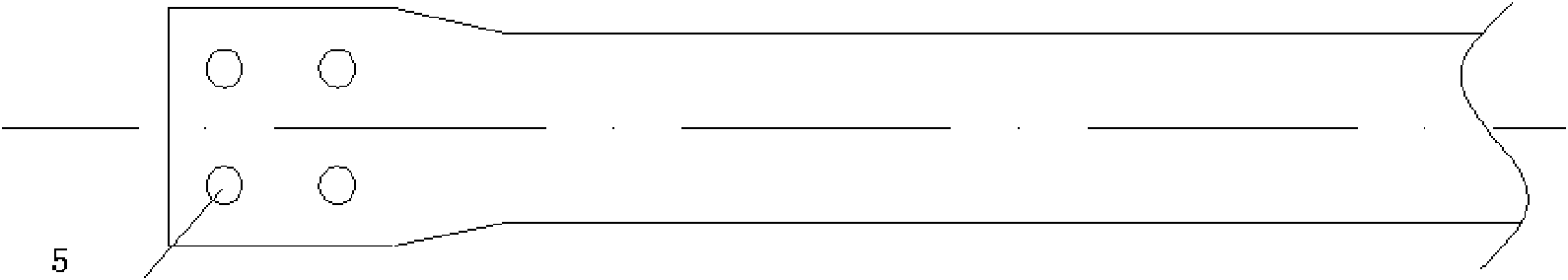

[0046] The insulating tubular busbar with a current of 4000A includes: insulating tubular busbar conductor 1, inner conductive tube 2, cooling holes 3, heat dissipation space in the tube 4 and end plate opening 5, wherein: insulating tubular busbar conductor 1 is located on the outermost layer, An inner conductive tube 2 is provided inside the insulating tubular bus conductor 1 , and a cooling hole 3 is provided at the end of the insulating tubular bus conductor 1 .

[0047] The insulated tubular busbar conductor 1 is specifically a copper tube with an outer diameter of 80 mm and an inner diameter of 60 mm, and the copper content of the copper tube is >99.4%;

[0048] The inner conductive tube 2 is specifically a copper tube with an outer diameter of 50mm and an inner diameter of 40mm, and the copper content of the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com