Upper inlet wind type burner

A technology of burners and gas nozzles, which is applied in the directions of burners, gas fuel burners, combustion methods, etc., can solve the problems of large difference in heat load, inconsistent flame height, weak flame, etc., to prevent nozzle blockage and improve efficiency. , the effect of a short but powerful flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

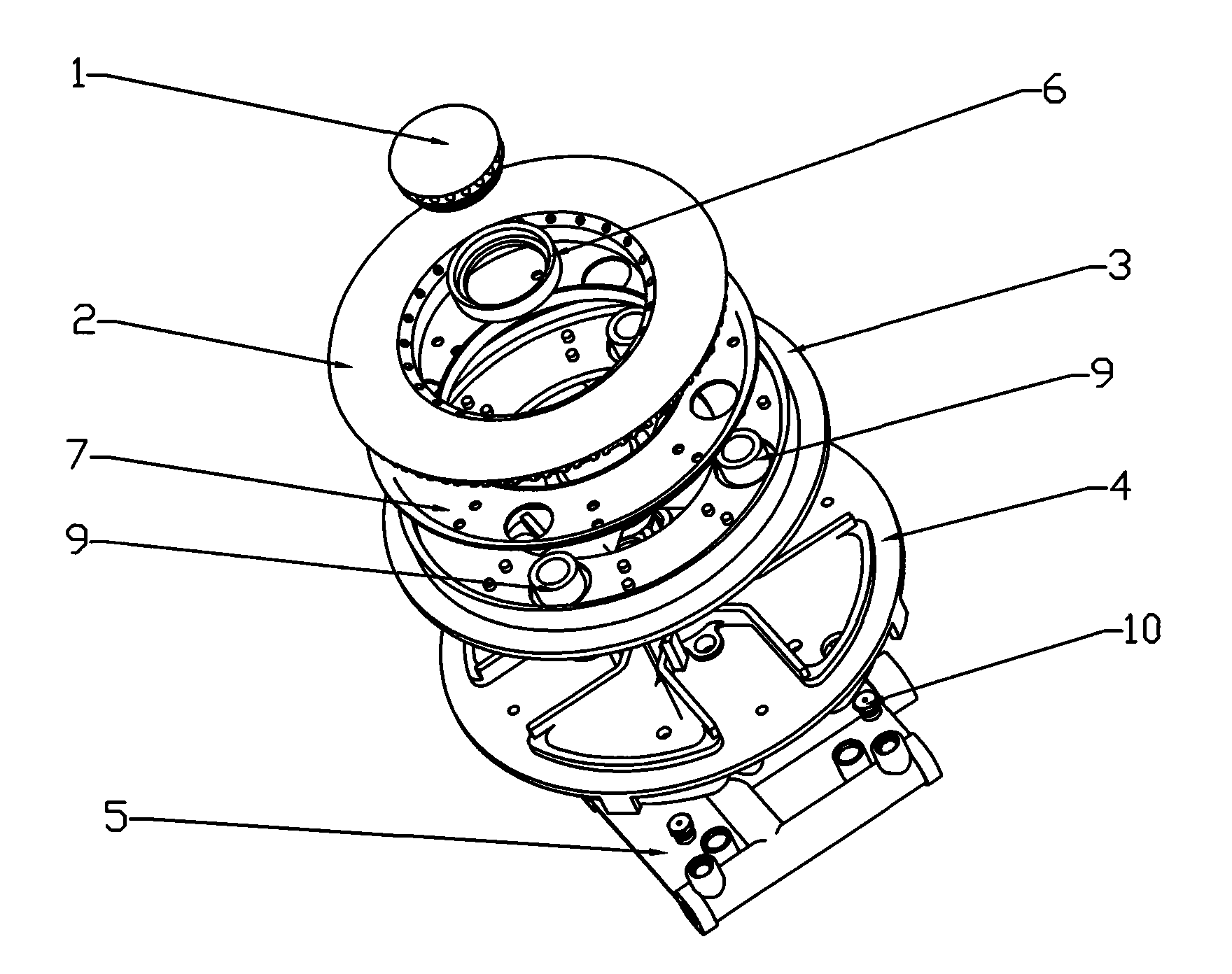

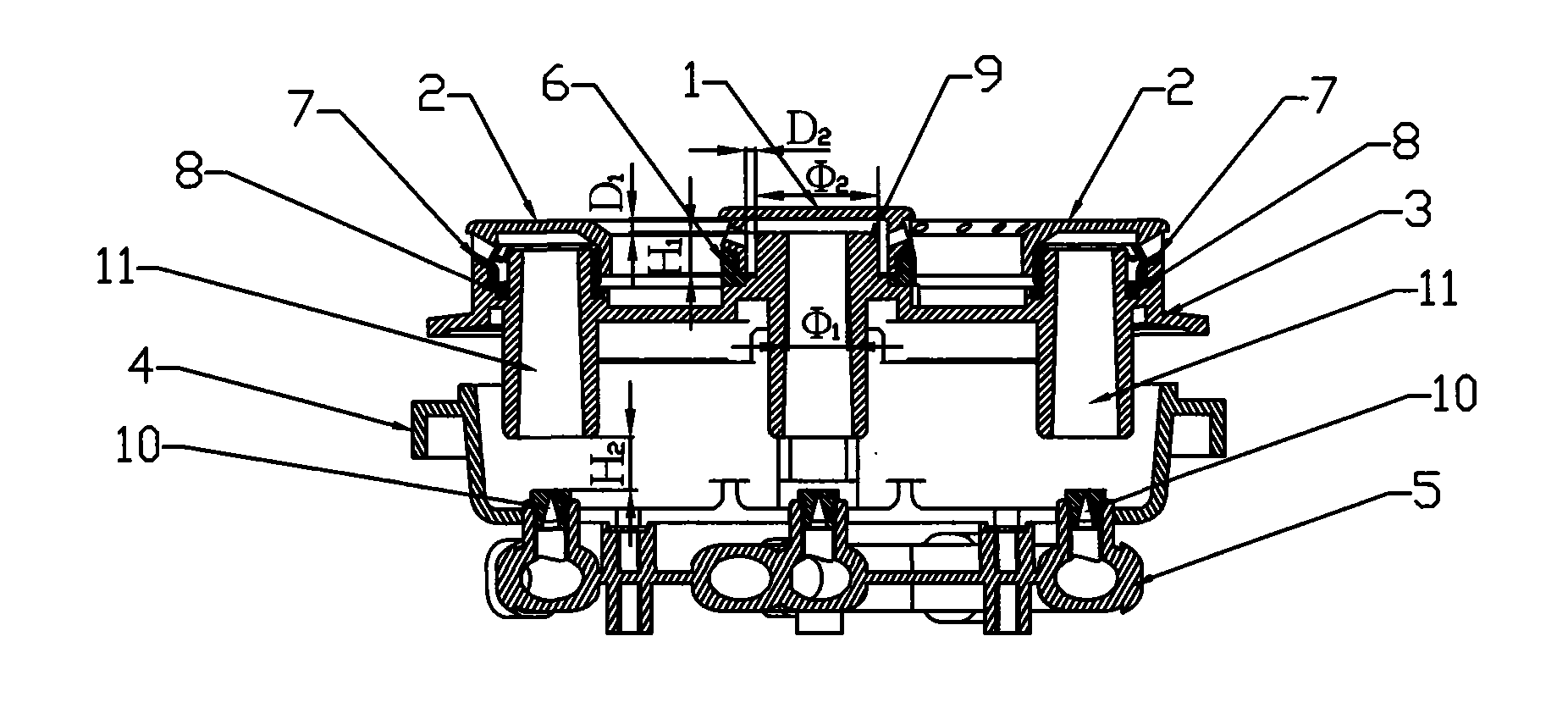

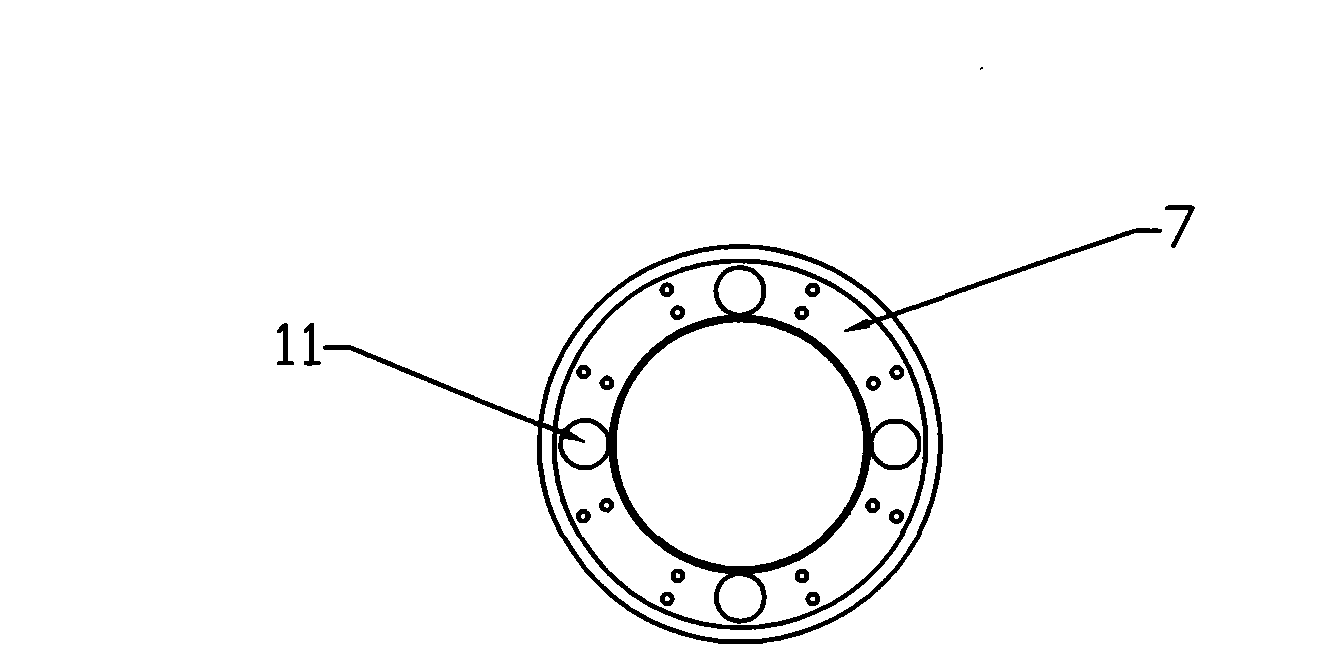

[0023] Such as Figure 1~5 As shown, the present invention discloses an upper air intake burner, which includes a central fire cover and an outer fire cover, a burner head, a base and a gas distribution pipe arranged sequentially from top to bottom, and the burner head is provided with five injection pipes, There is a gas mixing chamber on the base, five gas nozzles on the gas distribution pipe, and a gas distribution piece between the outer fire cover and the burner head. The gas distribution piece is in the shape of an annular groove. The positioning hole matched with the shooting tube, the upper end of the annular groove of the gas distributor is provided with an outward fold, the gas distributor is installed on the burner through the positioning hole, the outer fire cover is covered on the gas distributor; the center fire cover There is a fire cover seat between the furnace head and the fire cover seat. The fire cover seat is a cylindrical structure with a stepped inner ho...

Embodiment 2

[0025] In this embodiment, the values of each parameter are limit values: H 1 = 2mm, D 2 =D 1 = 2.6mm, k 2 =3.9,k 1 =2.08, Φ 1 =10mm, Φ 2 =20.8mm, H 2=6mm, except that, all the other structures and functions are consistent with Embodiment 1. Although the value in this embodiment is the minimum limit value, the performance of the burner is still significantly improved compared with similar products, and it can still ensure that the injection tube has a strong injection force, the gas and air are fully mixed, and the flame is short and powerful. There are no defects such as yellow flame and tempering. If the value is further reduced, minor defects will develop into major defects.

Embodiment 3

[0027] In this embodiment, the values of each parameter are the maximum limit value: H 1 =7mm,D 2 =D 1 = 2.4mm, k 2 =4.1,k 1 =2.29, Φ 1 =10mm, Φ 2 =22.9mm,H 2 =10mm, except that, all the other structures and functions are consistent with Embodiment 1. This embodiment can also ensure strong ejection force of the ejector tube, sufficient mixing of gas and air, short and powerful flame, and no defects such as yellow flame and tempering. If the value is further increased, defects will start to appear.

[0028] The above embodiments are burners designed using the functional relationship and value range provided by the present invention, and their working conditions and work efficiency can reach a relatively good state. The following table shows that the functional relationship and value range provided by the present invention are not adopted. Burners designed for the value range, they have more or less defects, as shown in the following table:

[0029] parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com