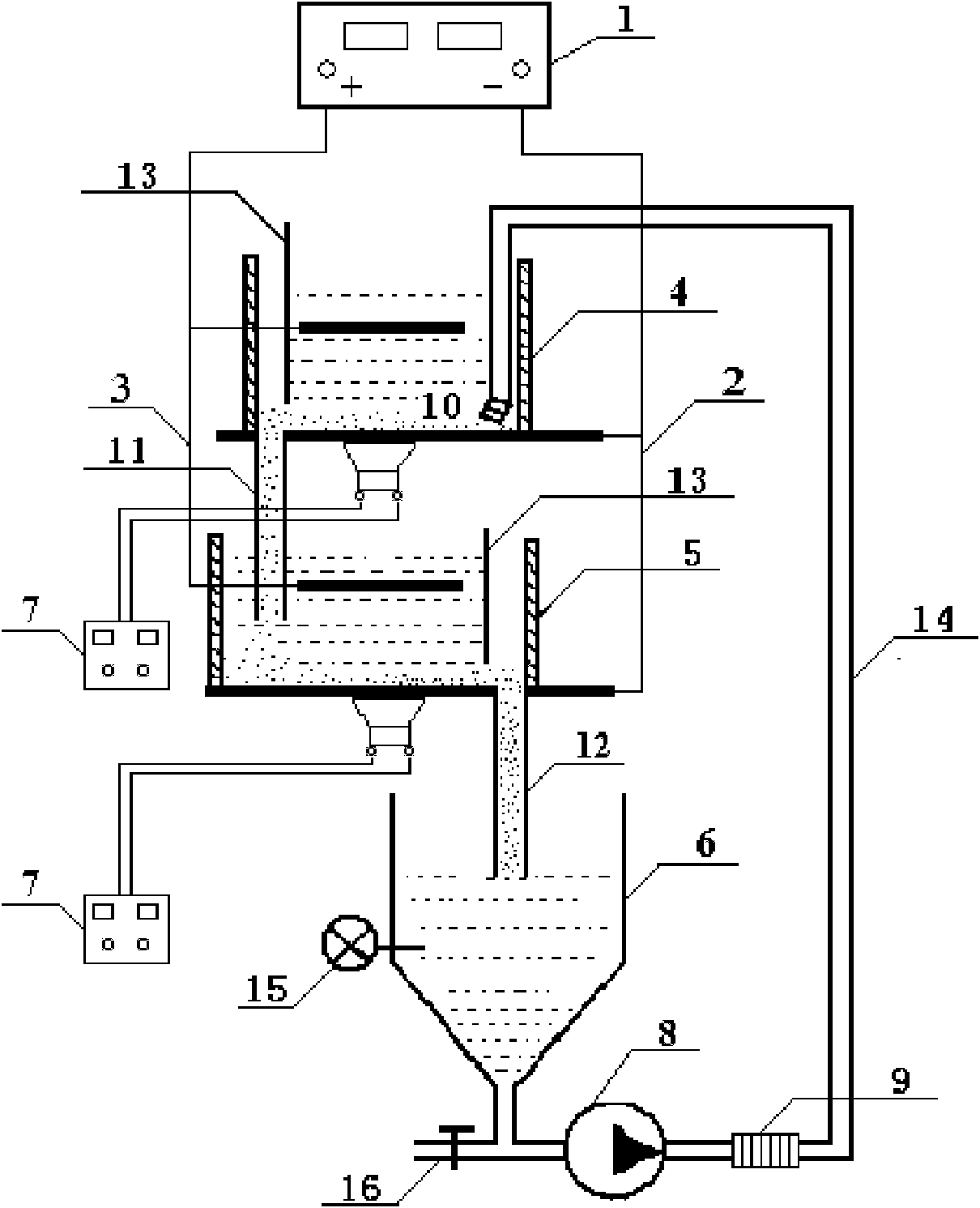

Electroplating device of copper plating of graphite powder and technique

An electroplating device and electroplating process technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of unfavorable copper deposition, low deposition rate, low limit current, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The base material is 200 mesh flake graphite, and the specific operation steps are as follows:

[0042] Graphite pretreatment

[0043] A: Use muffle furnace for degreasing at high temperature to degrease, temperature: 600°C, time: 30min;

[0044] B: Ultrasonic roughening with concentrated nitric acid ultrasonic roughening, temperature: room temperature, time: 20min;

[0045] C: Wash with distilled water until neutral;

[0046] flow copper plating

[0047] Plating solution preparation and operating conditions: copper sulfate 10g dm -3 , graphite powder 15g·dm -3 , concentrated sulfuric acid 5cm 3 · dm -3 , Glacial acetic acid 0.2cm 3 · dm -3 , formamide 0.3cm 3 · dm -3 , the number of plating tank combinations is 2; the temperature is 60°C; the flow rate of the plating solution is 12dm -3 min -1 ;Ultrasonic frequency 20kHz current density 30A·dm -2 ,; time 20min.

[0048] (3) Post-treatment of graphite powder copper plating

[0049] A: Copper-clad graphite...

Embodiment 2

[0053] Base-material is 200 order graphite flakes, and difference from embodiment 1 is:

[0054] flow copper plating

[0055] Plating solution preparation and operating conditions: copper sulfate 10g dm -3 , graphite powder 15g·dm -3 , sodium hypophosphite 5g·dm -3 , concentrated sulfuric acid 5cm 3 · dm -3 , Glacial acetic acid 0.2cm 3 · dm -3 , formamide 0.3cm 3 · dm -3 ; The number of plating tank combinations is 2; the temperature is 60°C; the flow rate of the plating solution is 12dm -3 min -1 ; Ultrasonic frequency 20kHz; Current density 30A·dm -2 ; Time 20min.

[0056] All the other steps are the same as in Example 1.

[0057] The copper clad graphite powder composite material prepared in this example has a mass fraction of copper of 60%, and the coating is dense and uniform.

Embodiment 3

[0059] Base-material is 200 order graphite flakes, and difference from embodiment 1 is:

[0060] flow copper plating

[0061] Plating solution preparation and operating conditions: copper sulfate 8g dm -3 , graphite powder 15g·dm -3 , sodium hypophosphite 10g·dm -3 , concentrated sulfuric acid 5cm 3 · dm -3 , Glacial acetic acid 0.2cm 3 · dm -3 , formamide 0.3cm 3 · dm -3 ; The number of plating tank combinations is 2; the temperature is 60°C; the flow rate of the plating solution is 12dm -3 min -1 ; Ultrasonic frequency 20kHz; Current density 30A·dm -2 ; Time 20min.

[0062] All the other steps are the same as in Example 1.

[0063] The copper-clad graphite powder composite material prepared in this example has a mass fraction of copper of 65%, and the coating is dense and uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com