Continuous production device for culturing Microalgae by closed piston flows and production method thereof

A production device and plug flow technology, which is applied in the field of continuous production devices for closed plug flow cultivation of microalgae, can solve the problems of pollution, biological pollution, and high energy consumption, achieve simple and convenient operation, uniform reaction distribution, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

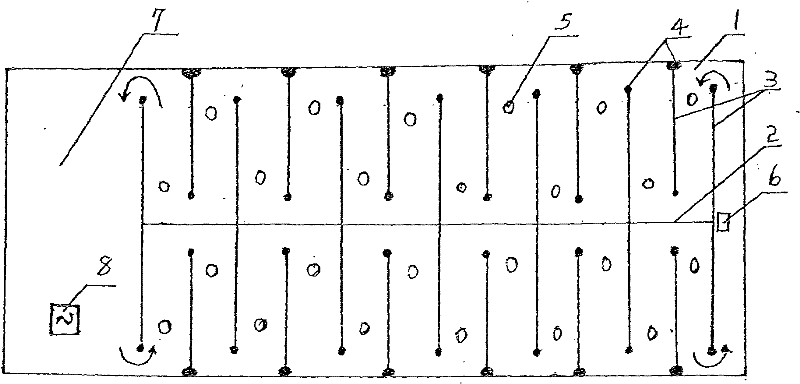

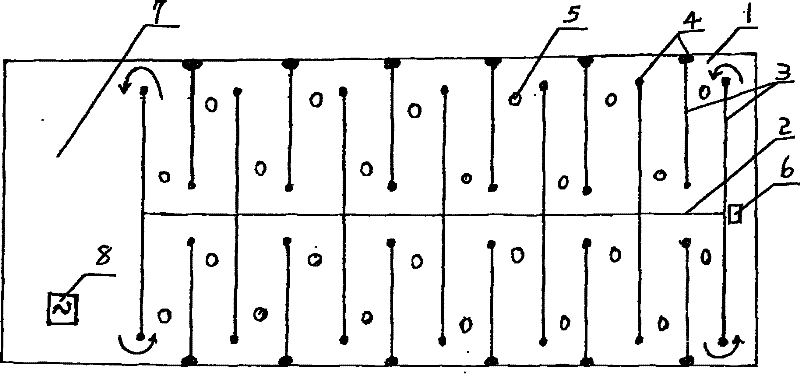

[0025]The continuous production device for the closed plug flow cultivation of microalgae provided by the present invention includes 500 transparent culture unit devices 1, which are arranged sequentially and stacked up and down in parallel with 5 layers of continuous production devices fixed on the ground frame base in parallel and spaced intervals. The height of the cultivation unit device is 2 meters, and the width is 3 meters. A horizontal centerline partition 2 is established in the length of 40 meters. The upright baffles 3 arranged longitudinally and intersecting at intervals, one upright side of each adjacent two baffles are respectively connected with the long outer side of the unit device or the centerline partition, and the other upright side is respectively connected with the centerline partition Or the long outer side of the unit device is spaced at a certain distance to form a baffle channel, and the microalgae culture solution is continuously pushed and flowed th...

Embodiment 2

[0028] The device and steps used in Example 2 are the same as in Example 1, except that the microalgae is Cyanococcus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com