Weather resistance permeable material and application thereof

A water-permeable material and weather-resistant technology, which is applied in the direction of climate sustainability, pavement paved with prefabricated blocks, and condensed pavement paved on-site, etc., can solve the complex production process of ceramic permeable bricks and large one-time investment scale , short service life and other problems, to improve the ability of anti-oxidation and anti-ultraviolet rays, improve the urban water cycle, and promote the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

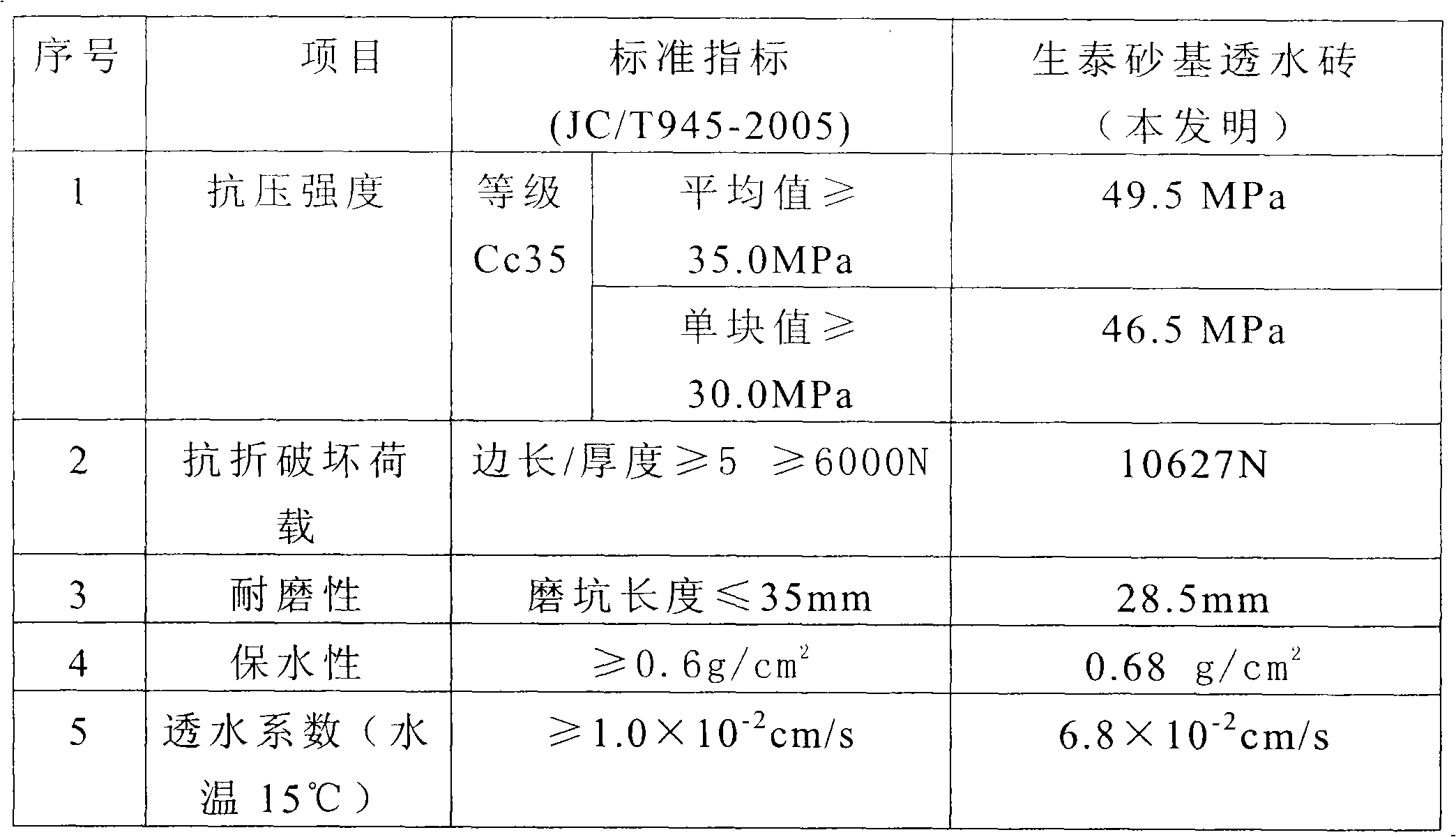

[0031] Take 100g of blue-colored 0.4-0.2mm mesh quartz sand, 4.6g of hydrogenated bisphenol A epoxy resin, 1.4g of aliphatic polyamine curing agent, and 5600.12g of glycidoxypropyltrimethoxysilane as the coupling agent , light stabilizer UV-320: 0.012g and antioxidant 1010: 0.006g; after mixing, it is molded into a permeable brick, and its performance index is compared with that of ordinary permeable bricks:

[0032]

example 2

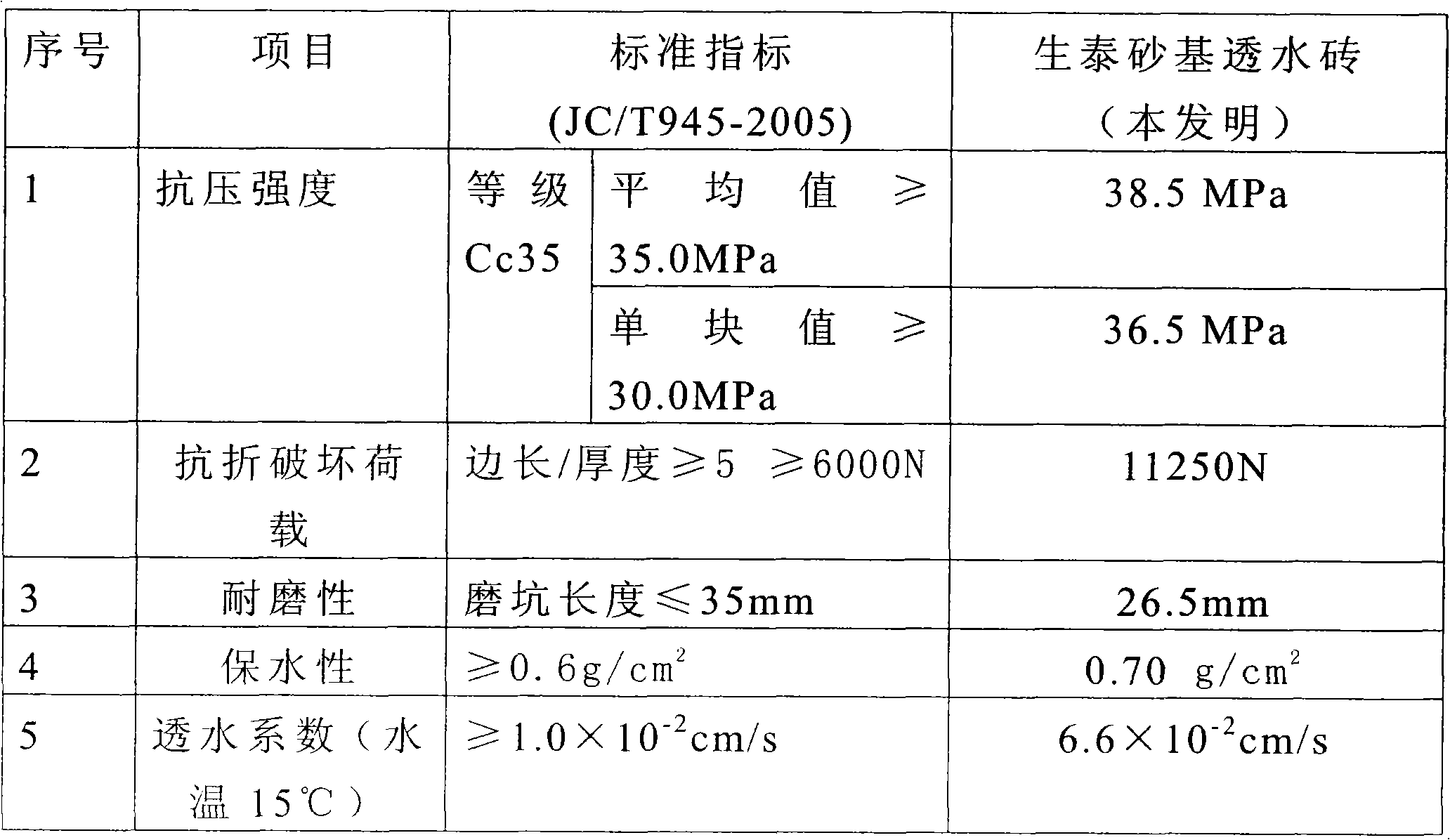

[0034] Take 10Kg of 0.07-0.2mm mesh quartz sand dyed green, 600g of hydroxyl-containing acrylic resin and 200g of 75% HDI biuret as binder, 550:3g of silane coupling agent, 0.6g of light stabilizer UV-326 and Antioxidant 10100.9g, curing reaction catalyst 0.5% lead naphthenate solution 0.5g, dibutyltin dilaurate 0.9g; after mixing, mold it into permeable bricks, and measure its compressive strength to 38MPa.

[0035]

example 3

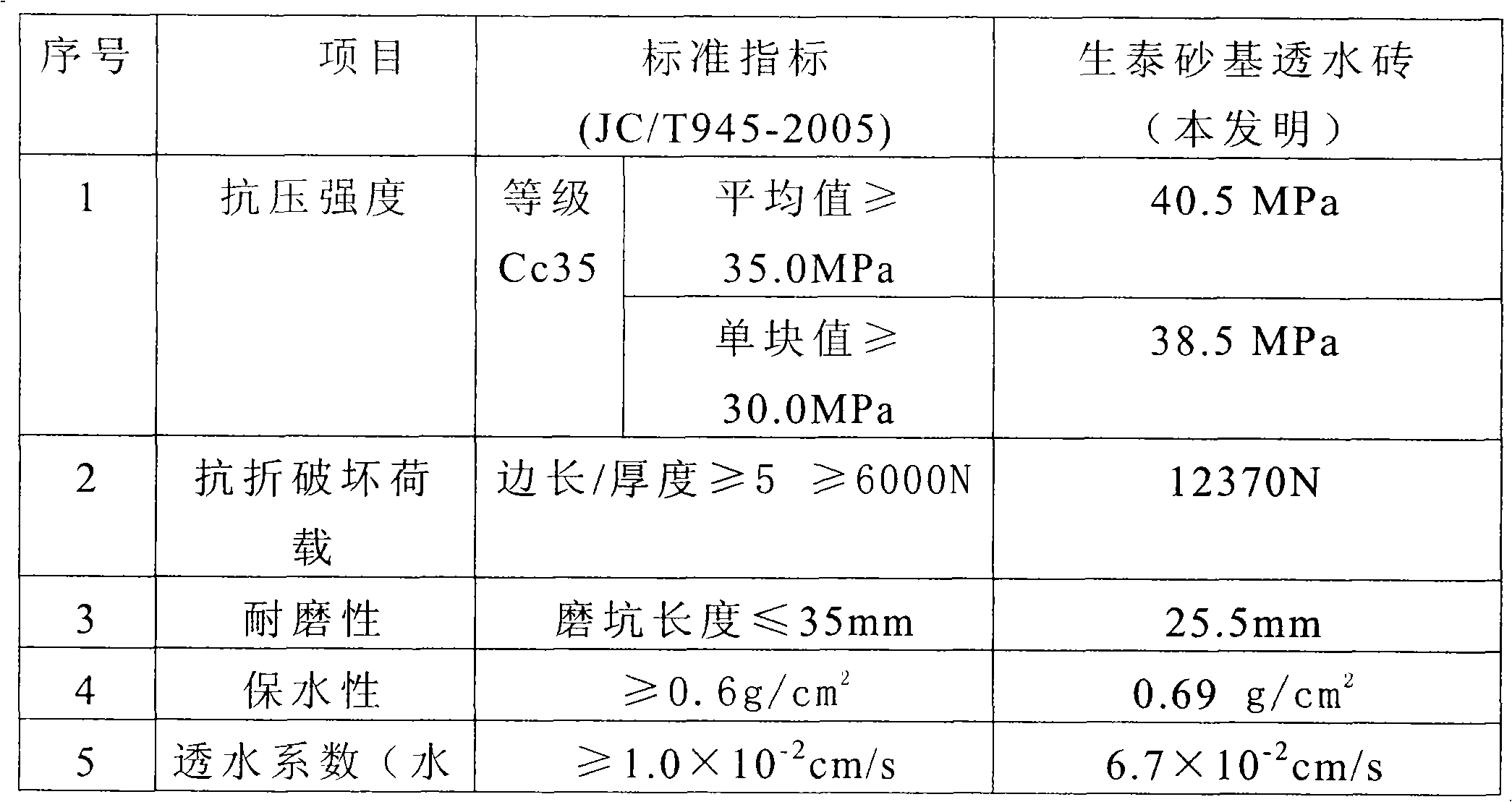

[0037] Take 10Kg of 0.2-0.4mm quartz sand dyed black, 600g of 70% 650 polyester solution and 560g of 75% HDI biuret solution as binder, add 550:5g of silane coupling agent, UV light stabilizer -327: 0.6g; antioxidant 1222: 0.9g, zinc naphthenate 1.8g; chain extender and crosslinking agent is trimethylolpropane 20g; methyl ethyl ketone 15g is used as urethane grade solvent; made after mixing The sample block is measured to have a compressive strength of 40.3MPa.

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com