Sponge-forming liquid silicone-rubber composition and silicone rubber sponge made therefrom

A technology of liquid silicone rubber and composition, which is applied in the field of silicone rubber sponge, can solve the problems of insufficient uniformity of distribution, high shrinkage rate of molded sponge body, poor mold cavity shape reproducibility, and insufficient fineness of sponge body pores, etc., to achieve the goal of reducing shrinkage rate Effect

Active Publication Date: 2010-03-03

DOW CORNING TORAY CO LTD

View PDF6 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this composition is characterized by high shrinkage of the molded sponge and poor mold cavity shape reproducibility

In addition, the pores of the obtained sponge are not fine enough and the distribution is not uniform enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0043]

preparation example 2

preparation example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

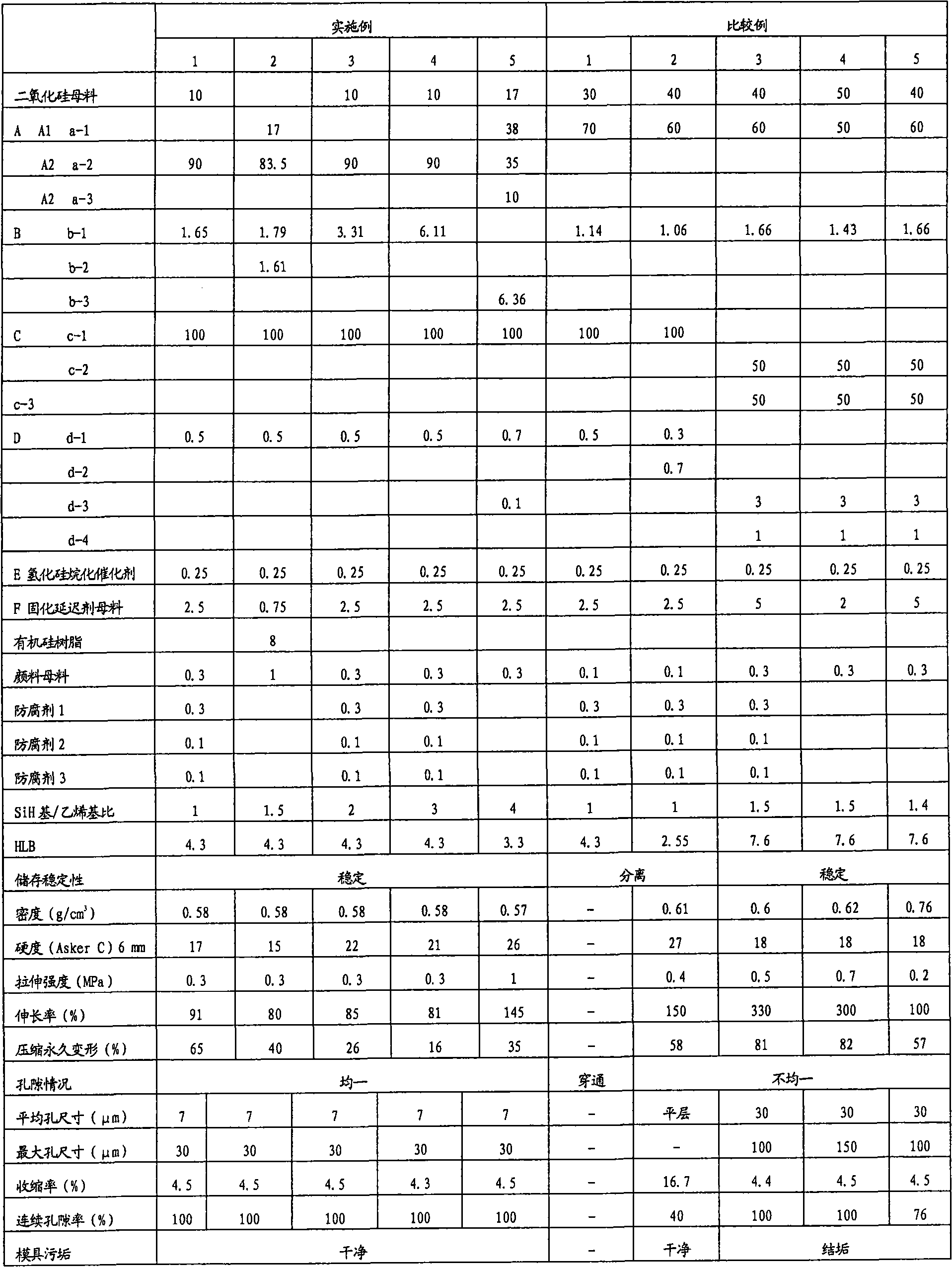

A sponge-forming liquid silicone-rubber composition comprising: a diorganopolysiloxane (A) comprising a diorganopolysiloxane (A1) that has alkenyl groups on both molecular terminals and does not haveany alkenyl groups in molecular side chains; and a diorganopolysiloxane (A2) that has two or more alkenyl groups in molecular side chains; an organohydrogenpolysiloxane (B) that has in one molecule atleast two silicon-bonded hydrogen atoms; a mixture (C) composed of water and inorganic thickener; an emulsifier (D); a hydrosilylation-reaction catalyst (E); and a curing retarder (F). The aforementioned sponge-forming liquid silicone-rubber composition provide a silicone-rubber sponge that has a reduced coefficient of shrinkage upon molding, does not bleed out non-cross-linked components, and has a fine, uniform, and continuous porosity.

Description

technical field [0001] The present invention relates to a sponge-forming liquid silicone rubber composition and a silicone rubber sponge formed from the composition. Background technique [0002] Since silicone rubber sponge is a material that is excellent in heat resistance, has weather resistance, is lightweight, and has low thermal conductivity, it is used in automobile parts, image forming equipment such as copiers, rollers and belts of printers, various sealing parts, etc. get applied. Hitherto, silicone rubber sponges have been manufactured by blending various thermally decomposable organic blowing agents or various volatile components. However, the use of such compositions is accompanied by difficulties in molding and poor mold cavity shape reproducibility. [0003] Japanese Unexamined Patent Application Publication (hereinafter referred to as "Kokai") No. 2005-62534 discloses a silicone rubber sponge-forming composition for manufacturing a fixing roller, which is o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L83/04C08J9/00C08J3/03

CPCC08K3/36C08J2201/024C08J2383/04C08J9/0014C08J9/0066C08K5/0025C08G77/20C08G77/12C08L83/04C08J9/28C08J2201/0504C08L83/00C08J3/03C08J9/00

Inventor 佐久间厚辻裕一

Owner DOW CORNING TORAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com