Cyanoacrylate compositions incorporating graphite platelets

A technology of cyanoacrylate and graphite flakes, applied in the direction of adhesive types, adhesive additives, ester copolymer adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

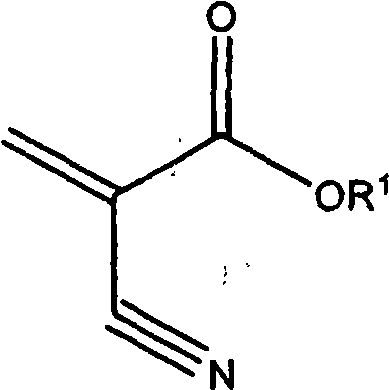

Image

Examples

Embodiment 1

[0052] Cyanoacrylate compositions labeled Samples 1-13, as listed in Table 1, were prepared by incorporating varying amounts of graphite platelet material into the cyanoacrylate compositions.

[0053] Prepare the composition by adding the indicated amount of graphite exfoliate material to the defined cyanoacrylate component and, if necessary, using gentle heat, stirring the composition until the graphite exfoliate material is uniformly dispersed within the composition .

Table 1

1. A stabilized ethyl cyanoacrylate-based one-part adhesive composition commercially available as LOCTITE 401 from Henkel Corporation, Rocky Hill, CT.

2. A toughened ethyl cyanoacrylate-based one-part adhesive composition incorporating a rubber modifier, commercially available as LOCTITE 435 from Henkel Corporation, Rocky Hill, CT.

3. Standard purity graphite flakes (-97% carbon content), available as TG-679 from Graftech Industries, Ltd., Cleveland, OH.

4. High purity graphite flakes (-99% ...

Embodiment 2

[0058] The shear strength of the cyanoacrylate composition in which the graphite sheet material was incorporated was measured. Specifically, by bonding 0.1 and 1% high-purity graphite flakes (~99% carbon content, available as TG-684HP from Graftech Industries, Ltd., Cleveland, OH), respectively, to a cyanoacrylate adhesive combination The cyanoacrylate compositions of samples 14 and 15 were prepared from LOCTITE 435 (commercially available from Henkel Corporation, Rocky Hill, CT). Compositions of Samples 14 and 15 were prepared by adding the indicated amount of graphite platelet material to the cyanoacrylate component and stirring under mild heating conditions until the graphite platelet material was uniformly dispersed within the composition.

[0059] The compositions thus prepared were tested for tensile shear strength according to ASTM No. D-1002, which test method is incorporated herein by reference. Tensile shear strength was determined using grit blasted mild steel lap ...

Embodiment 3

[0061] The bulk shear strength of certain polymeric materials was tested as follows. The cyanoacrylate adhesive composition LOCTITE 435 (available from Henkel Corporation, Rocky Hill, CT) prepared as sample 16 cyanoacrylate composition. The composition of Sample 16 was prepared by adding the indicated amount of graphite platelet material to the cyanoacrylate component, using gentle heat if necessary, stirring under mild heat until the graphite platelet material was uniformly dispersed in the within the composition. The composition of Sample 16 was applied between various substrates, including polycarbonate and polyvinyl chloride, and tested for bulk shear strength according to ASTM No. D-4501, which test method is incorporated herein by reference.

[0062] The bulk shear strength measurements of Sample 16 between various substrates were compared to those of a comparative cyanoacrylate composition of LOCTITE 435 without the graphite platelet component. When compared to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com