Low-shrinkage sprayable PP/PS blend alloy and preparation method thereof

A low-shrinkage, blended technology, applied in the direction of coating, etc., can solve the problem that the shrinkage rate of ABS cannot be achieved, and achieve good coating adhesion, easy access to raw materials, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

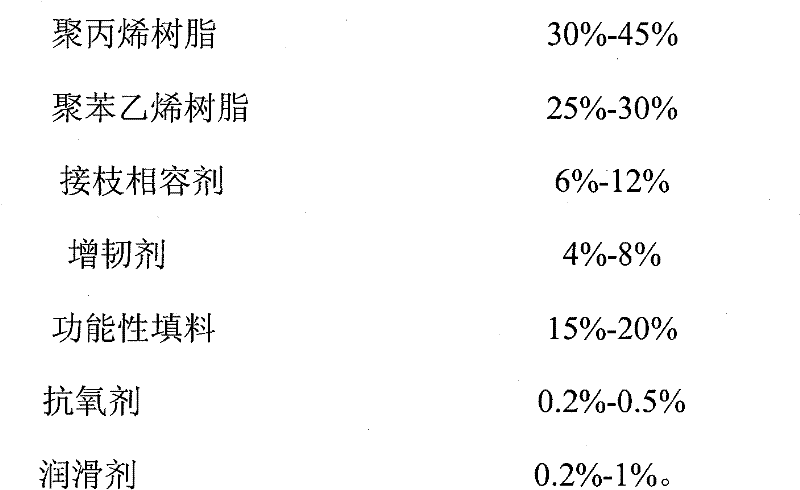

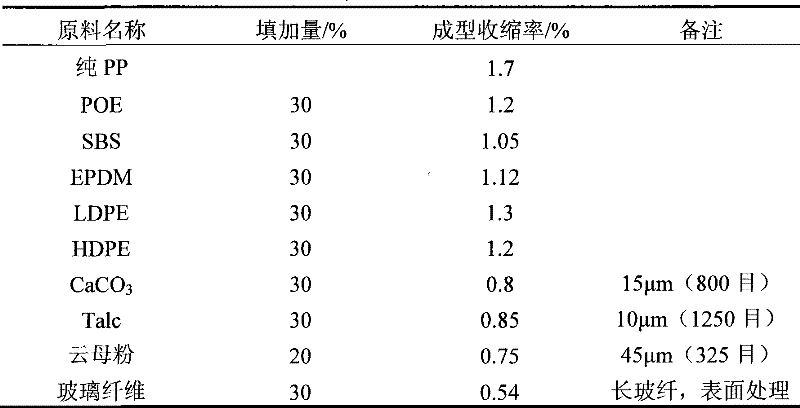

Method used

Image

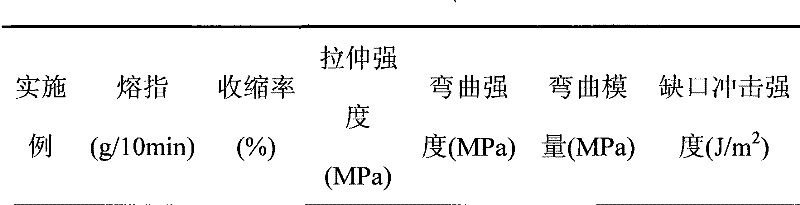

Examples

Embodiment 1

[0023] Homopolypropylene resin (MI=3) 45%

[0024] General-purpose polystyrene (GPPS) (MI=8) 28.6%

[0025] Polypropylene grafted polystyrene 10%

[0026] Polyolefin Elastomer 4%

[0027] Talc 12%

[0028] Antioxidant (1010 / 168=1:1 weight ratio) 0.2%

Embodiment 2

[0031] Copolymerized polypropylene resin (MI=6) 42%

[0032] General-purpose polystyrene (GPPS) (MI=8) 28.6%

[0033] Grafted product of styrene-butadiene-styrene block copolymer 8%

[0034] Polyolefin Elastomer 3%

[0035] Functional filler (talcum powder / barium sulfate=2:1) 18%

[0036] Antioxidant (DLTDP / TNPP=1:1 weight ratio) 0.2%

Embodiment 3

[0039] Homopolypropylene resin (MI=3) 35.5%

[0040] HIPS (MI=8) 29.3%

[0041] Grafted product of styrene-ethylene / propylene diblock copolymer 12%

[0042] Polyolefin Elastomer 4%

[0043] Talc 18.8%

[0044] Antioxidant (1010 / 168=1:1 weight ratio) 0.2%

[0045] EBS0.2%

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com