Preparation process of antioxidant composite powder

A composite powder and antioxidant technology, applied in the field of refractory materials, can solve the problems of the segregation of uneven components of the mixture, reduce the overall application effect, etc., and achieve the effects of rapid response, promotion and application value improvement, and overall performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 60%Al+10%Si+30%C

[0036] (1) Ball milling and mixing for 16 hours, the balls are Al 2 o 3 Balls, the ratio of ball to material is 1:2;

[0037] (2) The mixture is extruded into a prefabricated block with a relative density of 40%;

[0038] (3) Dry the prefabricated blocks at 100°C for 8 hours;

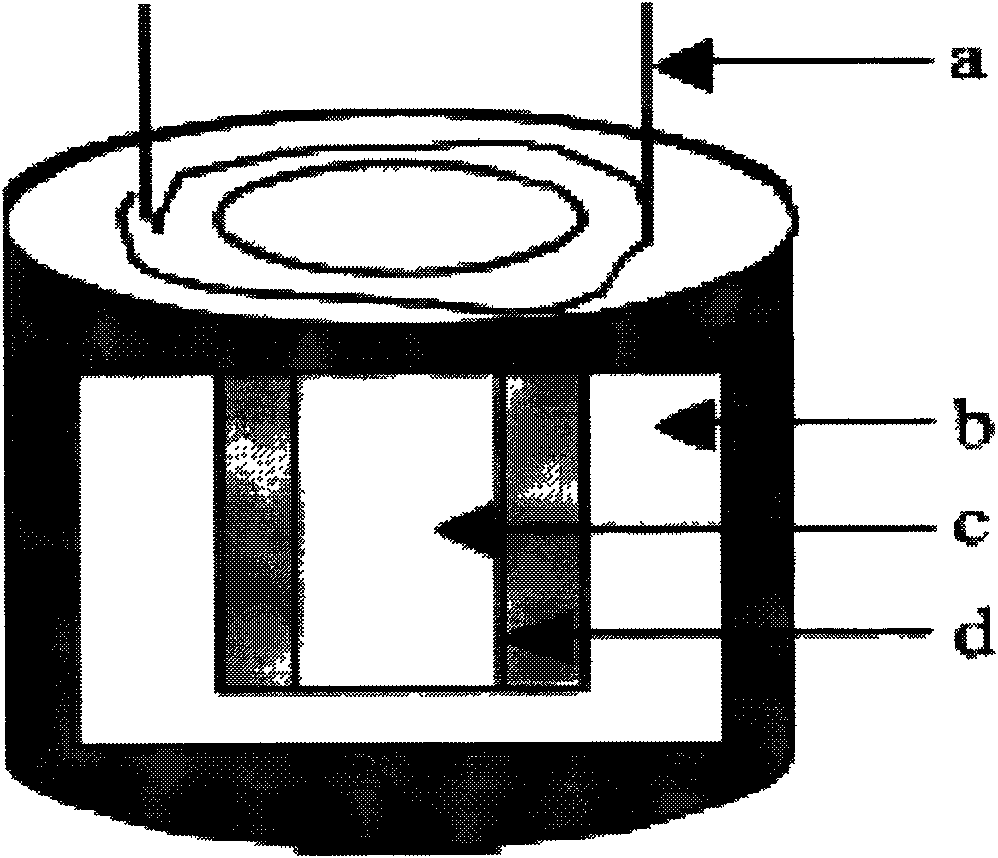

[0039] (4) the prefabricated block after drying is placed in the inner layer of the container made of carbon felt;

[0040] (5) Metal Al powder, diluent aluminum nitride and additive NH 4 Cl ball milling mixing 24 hours, this mixture is placed in the container outer layer of carbon felt as combustion-accelerating agent (diluent aluminum nitride in the accelerant is 20wt% of aluminum powder weight, additive NH 4 Cl is 1wt% of the total weight of the combustion aid)

[0041] (6) The ratio of the total weight of the combustion aid to the total weight of the reactants is: 3:1

[0042] (7) After the container is evacuated, it is filled with high-purity nitrogen to 8MPa, and t...

Embodiment 2

[0044] 58%Al+10%Si+32%C

[0045] (1) Ball milling and mixing for 24 hours, the balls are Al 2 o 3 Balls, the ratio of ball to material is 1:3;

[0046] (2) The mixture is extruded into a prefabricated block with a relative density of 40%;

[0047] (3) Dry the prefabricated blocks at 100°C for 8 hours;

[0048] (4) the prefabricated block after drying is placed in the inner layer of the container made of carbon felt;

[0049] (5) Metal Al powder, diluent aluminum nitride and additive NH 4 Cl ball milling mixing 24 hours, this mixture is placed in the container outer layer of carbon felt as combustion-accelerating agent (diluent aluminum nitride in the accelerant is 20wt% of aluminum powder weight, additive NH 4 Cl is 1wt% of the total weight of the combustion aid)

[0050] (6) The ratio of the total weight of the combustion aid to the total weight of the reactants is: 3.5:1

[0051] (7) After the container is evacuated, it is filled with high-purity nitrogen to 8MPa, and...

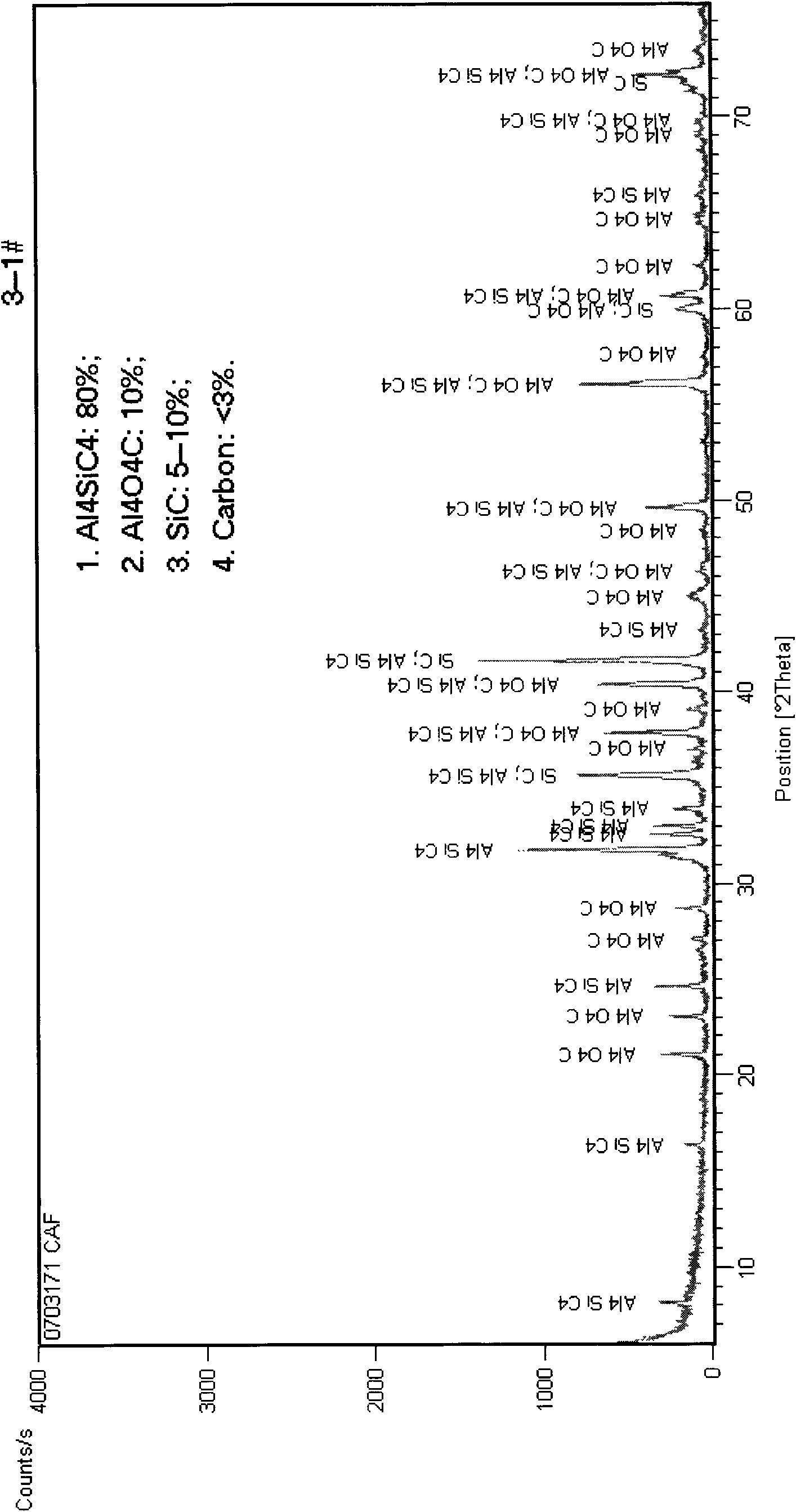

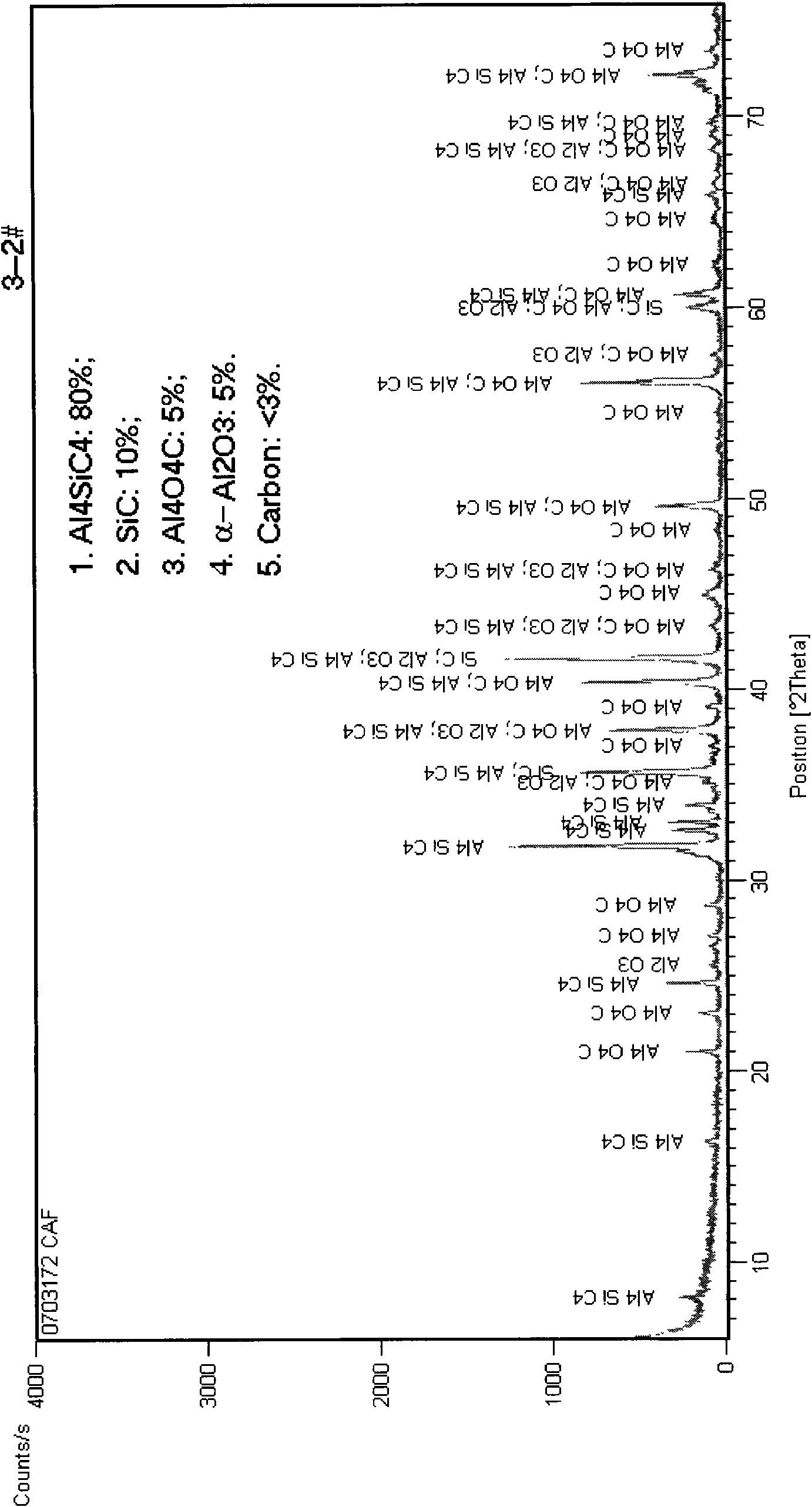

Embodiment 3

[0053] 56%Al+13%Si+31%C

[0054] (1) Ball milling and mixing for 30 hours, the balls are Al 2 o 3 Balls, the ratio of ball to material is 1:3;

[0055] (2) The mixture is extruded into a prefabricated block with a relative density of 60%;

[0056] (3) Dry the prefabricated blocks at 200°C for 6 hours;

[0057] (4) the prefabricated block after drying is placed in the inner layer of the container made of carbon felt;

[0058] (5) Metal Al powder, diluent aluminum nitride and additive NH 4 Cl ball milling mixing 24 hours, this mixture is placed in the container outer layer of carbon felt as combustion-accelerating agent (diluent aluminum nitride in the accelerant is 20wt% of aluminum powder weight, additive NH 4 Cl is 1wt% of the total weight of the combustion aid)

[0059] (6) The ratio of the total weight of the combustion aid to the total weight of the reactants is: 4:1

[0060] (7) After the container is evacuated, it is filled with high-purity nitrogen to 10MPa, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com