Large-scale self-aligning roller bearing ring quenching and cooling method

A technology for spherical roller bearings and bearing rings, which is applied in the direction of furnace types, furnaces, heat treatment equipment, etc., can solve the problems of hard quenching of bearing rings and uneven distribution of quenching stress, and achieve the reduction of quenching stress and cooling Homogeneous, deformation-cracking-reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

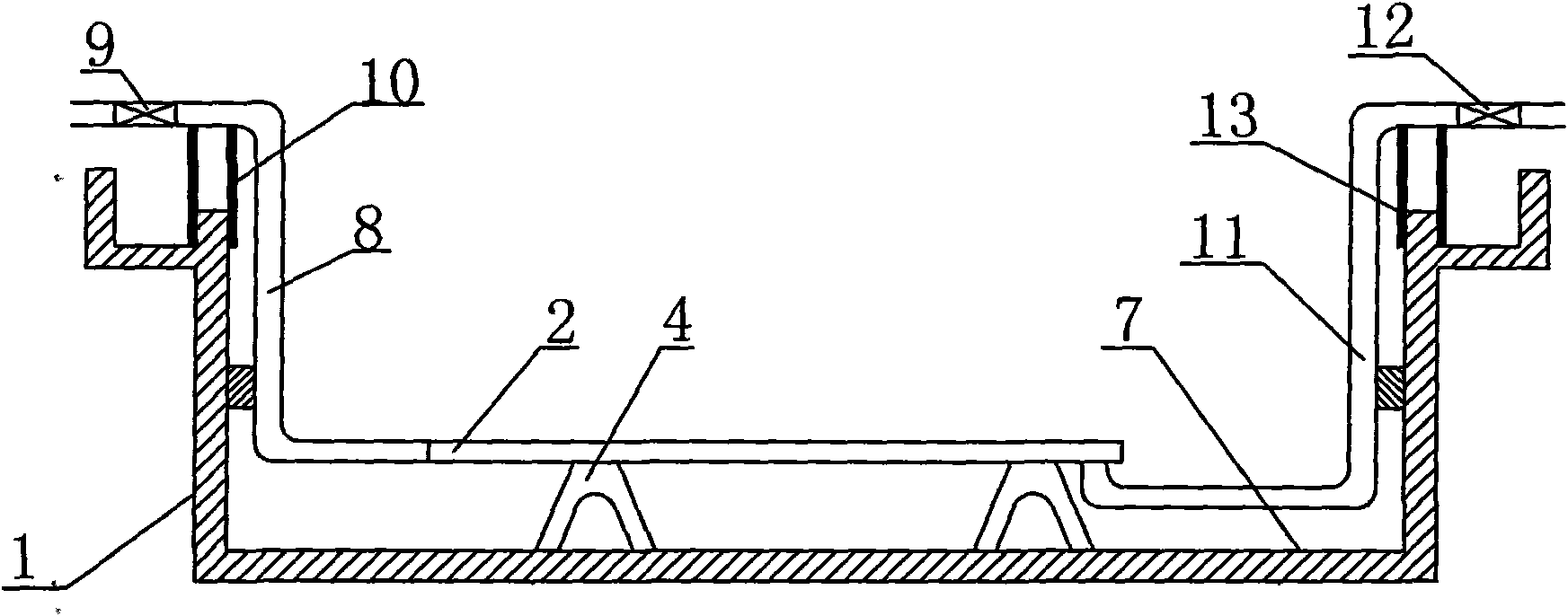

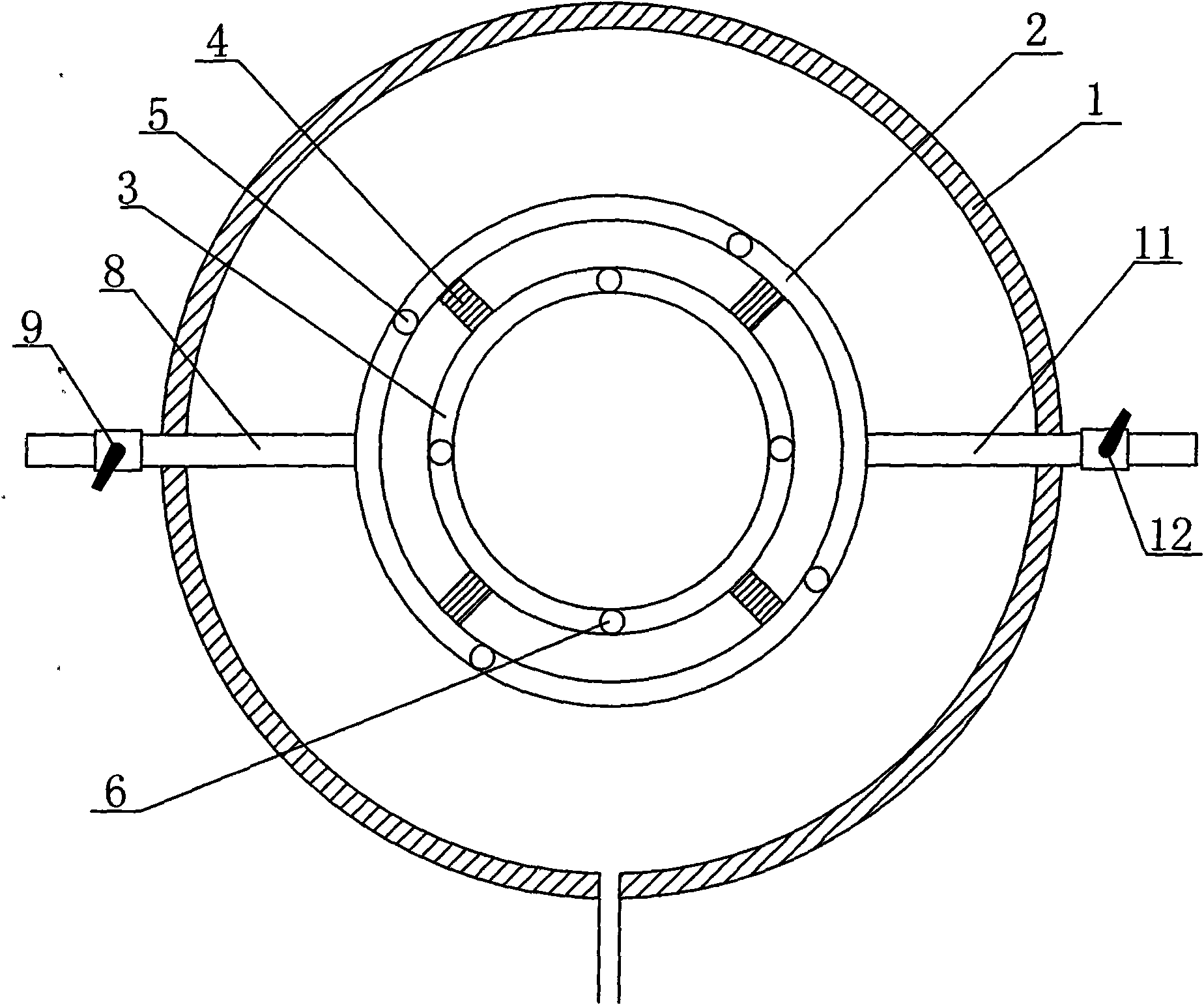

[0013] The quenching and cooling method for large spherical roller bearing rings, the technical key point is that the bearing rings use an air-cooling quenching device during the quenching process. The air-cooled quenching device includes an oil cylinder 1 and a cooling mechanism arranged at the bottom of the oil cylinder 1 . The cooling mechanism includes an outer annular blast pipe 2 , an inner annular blast pipe 3 and four supports 4 with the same structure. 32 air outlets 5 are evenly distributed on the circumference of the outer annular blast pipe 2, and 16 air outlets 6 are evenly distributed on the circumference of the inner annular blast pipe 3. The four brackets 4 are evenly distributed on the circumference, and the upper ends of the four brackets 4 are respectively inserted between the outer annular blast pipe 2 and the inner annular blast pipe 3, and are welded to the outer annular blast pipe 2 and the inner annular blast pipe 3 respectively. connect. The lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com