Double-cylinder by-pass type magnetorheological vibration damper

A magnetorheological shock absorber, general technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc. The effect of large variation range, large stroke and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

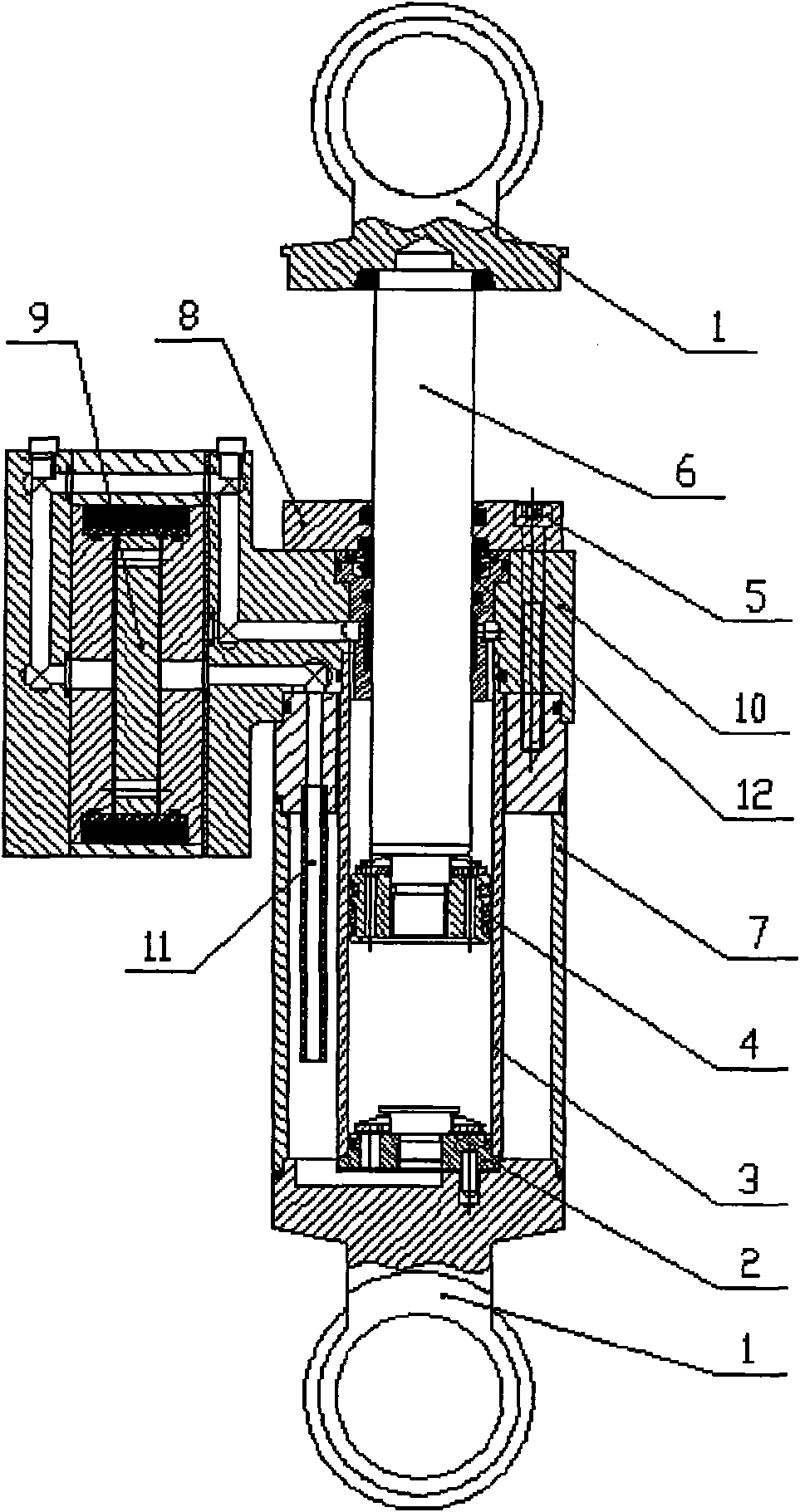

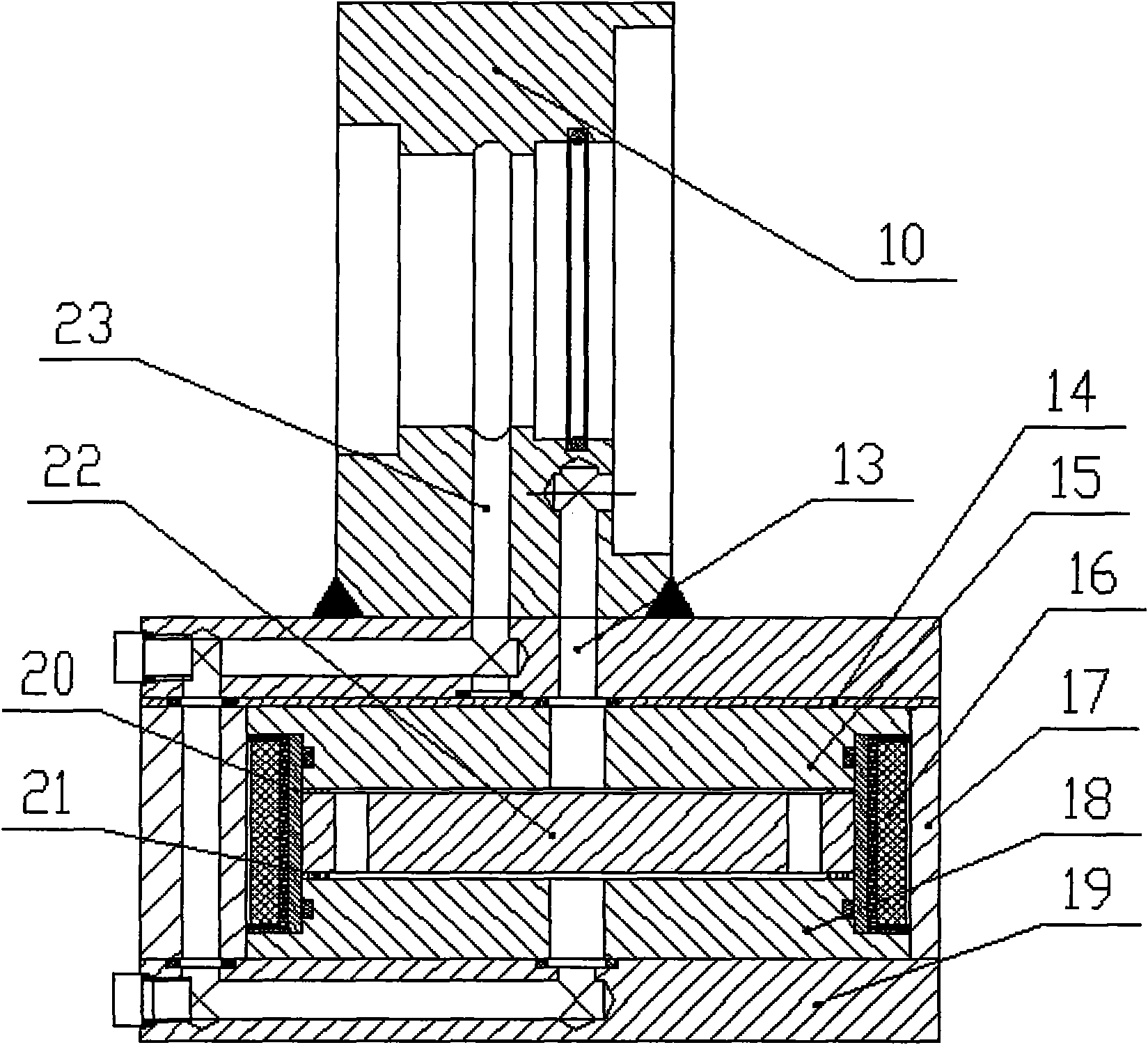

[0025] see figure 1 The double-barrel bypass magnetorheological shock absorber includes a working cylinder 3 and a liquid storage cylinder 7. A bottom valve 2 is installed on the lower part of the working cylinder 3. The inside of the working cylinder 3 is a working cylinder. The working cylinder 3 and the storage Between the liquid cylinders 7 is a liquid storage cylinder, which is used to compensate the volume change of the piston rod 6 during the movement of the shock absorber. In the channel, when the shock absorber is working, the working cylinder is filled with magnetorheological fluid, and a certain amount of air is left in the liquid storage cylinder. The piston 4 and the piston rod 6 move up and down in the working cylinder 3, and the piston 4 divides the working cylinder into the upper cavity of the working cylinder and the lower cavity of the working cylinder; a check valve is installed on the bottom valve 2 and the piston 4 to ensure that the liquid can only flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com