Synthesis method of luminescent material for insect-killing trapping lamp

A technology of luminescent materials and synthesis methods, applied in the direction of luminescent materials, devices for catching or killing insects, chemical instruments and methods, etc., can solve problems such as threats to health and life safety, increased cost, inconvenient, etc., and achieve reduction The effect of the number of eggs and population base in the field, the reduction of pesticide use, and the avoidance of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Components: 114.125g ammonium hydrogen phosphate, 18.780g strontium carbonate, 0.43g barium carbonate, 0.113g calcium carbonate, 4.404g cerium oxide, 3.810g boric acid, 3.445g lithium fluoride.

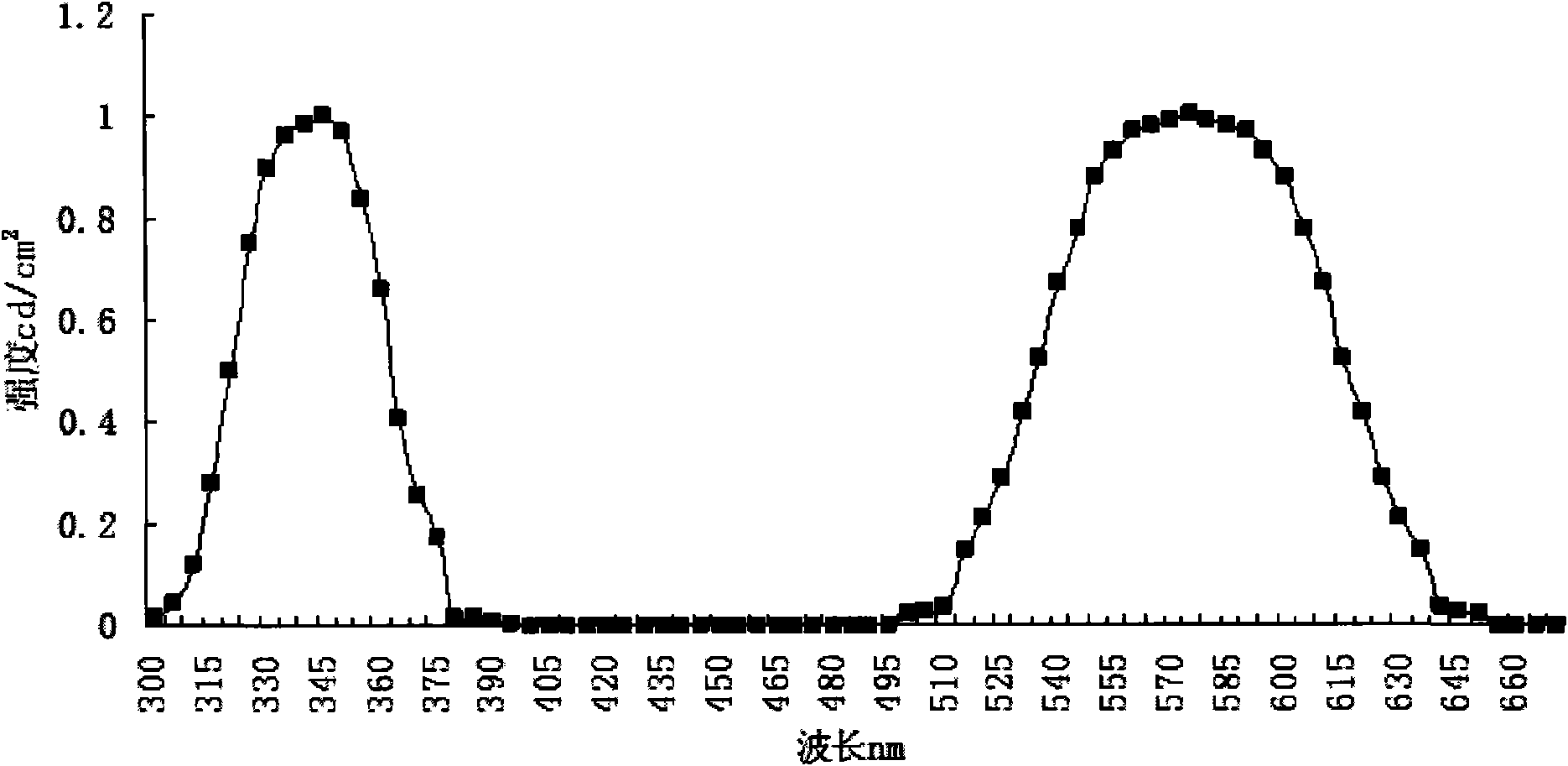

[0026] Thoroughly mix the above components evenly, among them, boric acid and lithium fluoride are used as flux, and they are mixed and ground for 30 hours in a corundum ball mill jar equipped with agate balls with a diameter of 10mm, and the mixed and ground oxides are put into a corundum crucible Burn for 3 hours in a high-temperature oxidizing atmosphere, and the temperature is controlled at 1400°C. The burnt product is crushed and passed through a 250-mesh sieve, followed by pickling treatment, and a 0.1% nitric acid solution is used to clean and sieve the product Suction filtration until neutral, drying at 100°C and passing through a 150-mesh sieve, again put the sieved product into a corundum crucible, and burn in a nitrogen-hydrogen (5% volume hydrogen nitrogen) mixed atm...

Embodiment 2

[0028] Components: 120.295g ammonium hydrogen phosphate, 19.562g strontium carbonate, 0.110g barium carbonate, 0.220g calcium carbonate, 4.585g cerium oxide, 6.045g boric acid, 4.596g lithium fluoride.

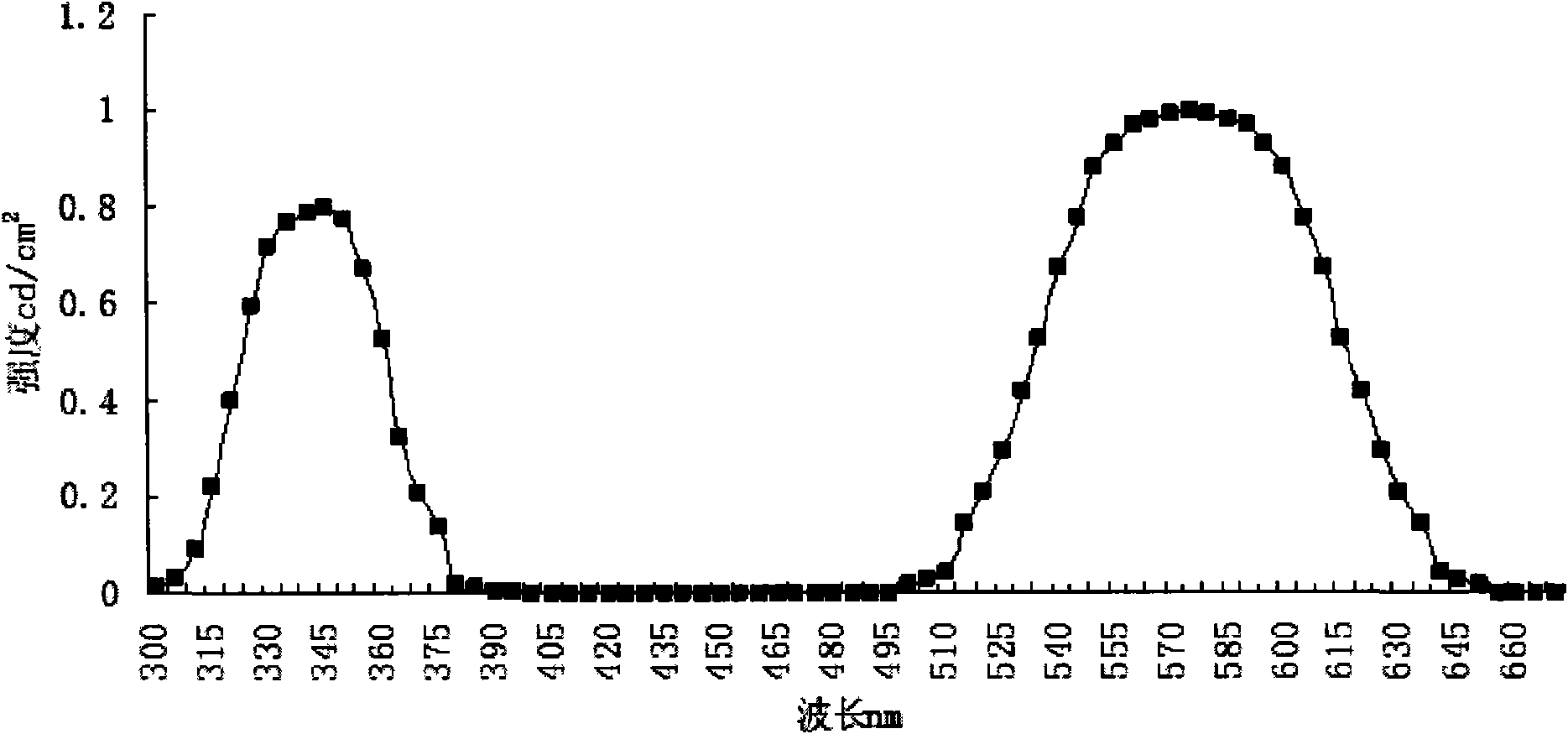

[0029] Thoroughly mix the above components evenly, in which boric acid and lithium fluoride are used as flux, and are mixed and ground for 40 hours in a corundum ball mill jar equipped with agate balls with a diameter of 10mm, and the mixed and ground oxides are put into a corundum crucible Burn for 3 hours in a high-temperature oxidizing atmosphere, and the temperature is controlled at 1300°C. The burnt product is crushed and passed through a 250-mesh sieve, followed by pickling treatment, and a 0.5% nitric acid solution is used to clean and sieve the product Suction filtration until neutral, drying at 120°C and passing through a 150-mesh sieve, again put the sieved product into a corundum crucible, and burn it in a nitrogen-hydrogen (5% volume hydrogen nitrogen) mixed atmosph...

Embodiment 3

[0031] Components: 125.115g ammonium hydrogen phosphate, 22.156g strontium carbonate, 0.730g barium carbonate, 0.050g calcium carbonate, 4.890g cerium oxide, 10.451g boric acid, 3.502g lithium fluoride

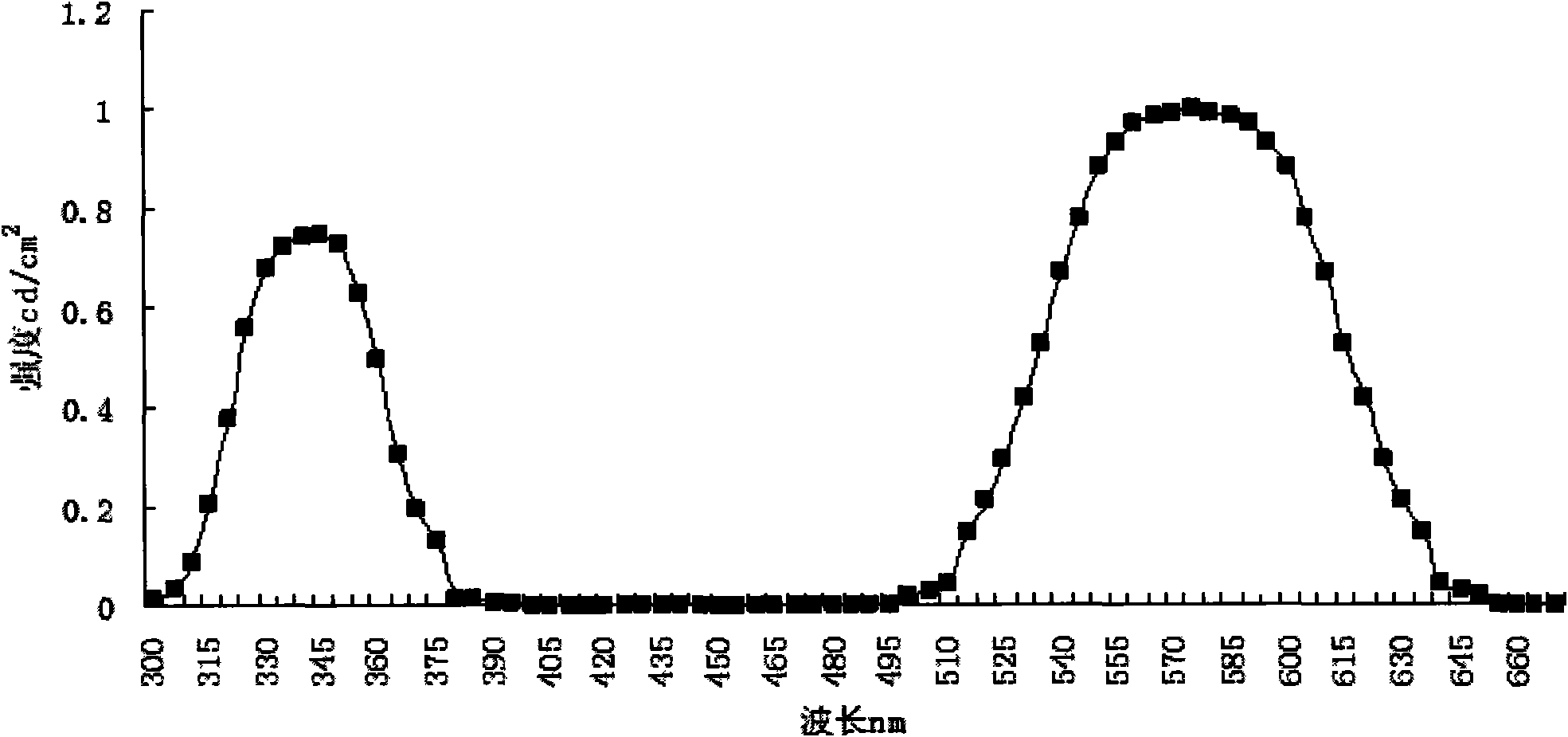

[0032] Thoroughly mix the above components evenly, among which boric acid and lithium fluoride are used as flux, and are mixed and ground for 35 hours in a corundum ball mill jar equipped with agate balls with a diameter of 10mm, and the mixed and ground oxides are put into a corundum crucible Carry out burning for 4 hours in a high-temperature oxidizing atmosphere, and the temperature is controlled at 1200 ° C. The burned product is crushed and passed through a 250-mesh sieve, followed by pickling treatment, and a 1% nitric acid solution is used to clean and sieve the product , until neutral, then suction filtered, dried at 120°C and passed through a 150 mesh sieve, again the sieved product was put into a corundum crucible, and burned in a nitrogen-hydrogen (5% volume hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com