Combined type electric mower

A pruning machine and a combined technology, which are applied to hedge trimming equipment, harvesters, lawn mowers, etc., can solve the problems of unsatisfactory pruning quality, labor-intensive operators, and heavy manual labor, etc., and are easy to popularize and use. , The effect of good pruning quality and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] figure 1 The power of the pruning machine shown is a 48V, 40AH power battery 2 and a 12V, 20AH vehicle power battery 3 developed by our country; the four-wheeled trolley 4 is an electric vehicle with a steering wheel 5. The solar cell 1 is placed on top of the carrying mechanism as auxiliary power for the trimmer.

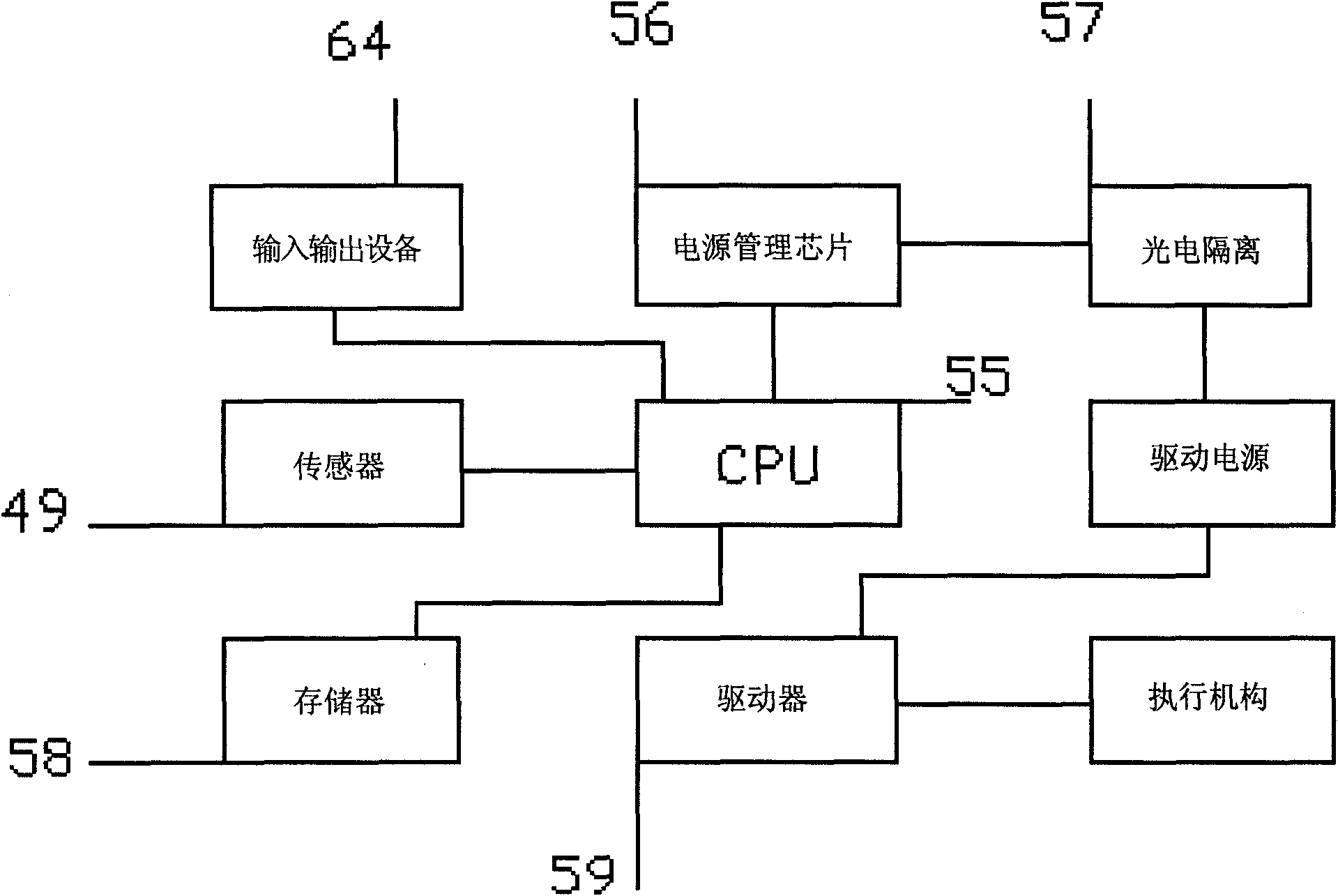

[0035] figure 2 The control system shown includes a CPU 55, a power management chip 56, a photoelectric isolation component 57, a memory 58, a drive module 59, and a position sensor 49. The CPU is an ARM9 series microprocessor. The control principle is: the control system captures the trim type and related parameters from the keyboard and console buttons, then generates the corresponding control algorithm according to the parameters, then calculates the number of pulses and pulse sending frequency of each control motor, calls the driving routine, and then Each motor sends pulses. In the process of sending pulses, it is judged whether the pulse sending is finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com