Improved semiconductor water cooling module for computer display card

A semiconductor and computer technology, which is applied in the field of semiconductor water cooling modules for computer graphics cards, and can solve problems such as unsuitable application occasions and small application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

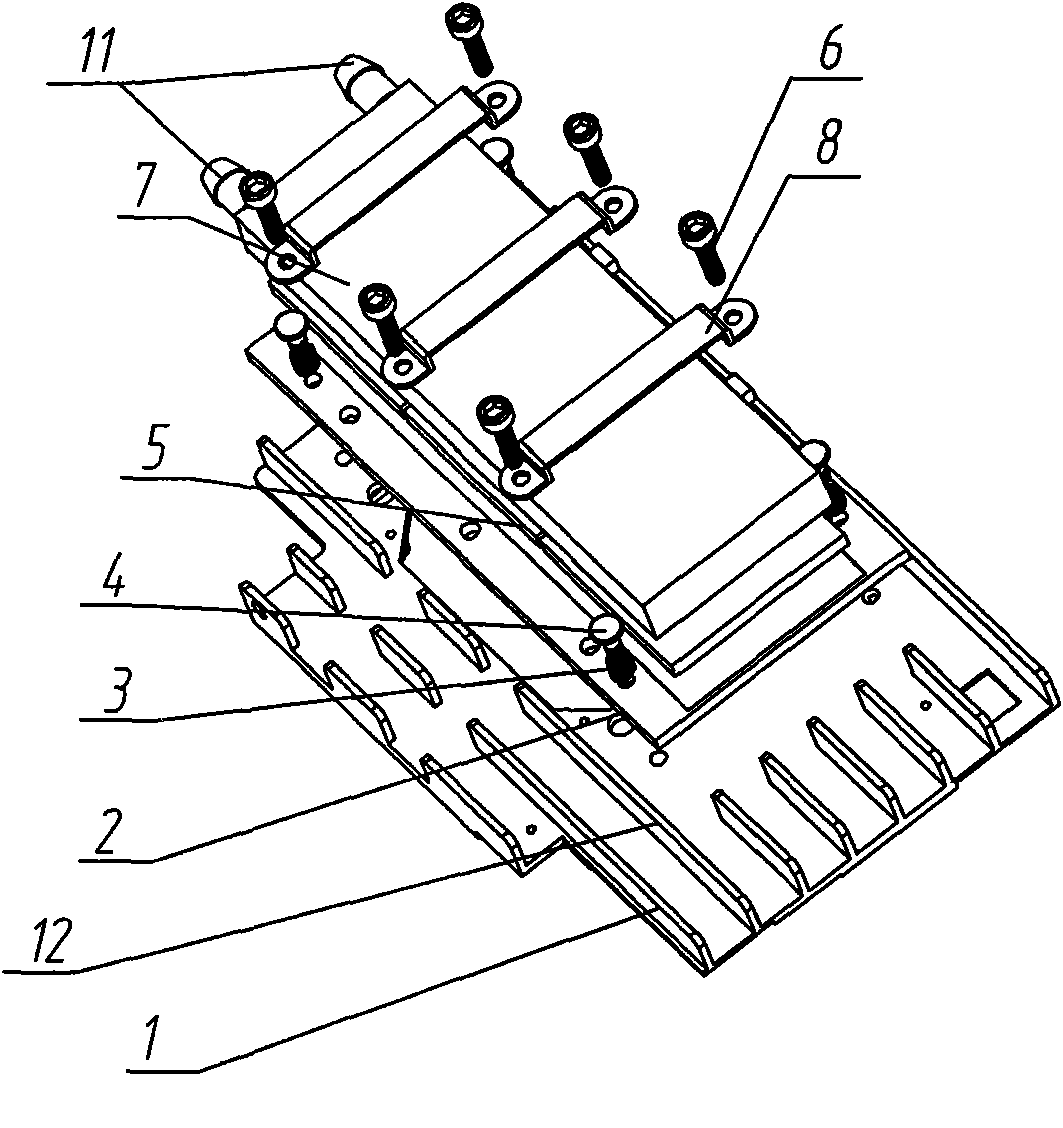

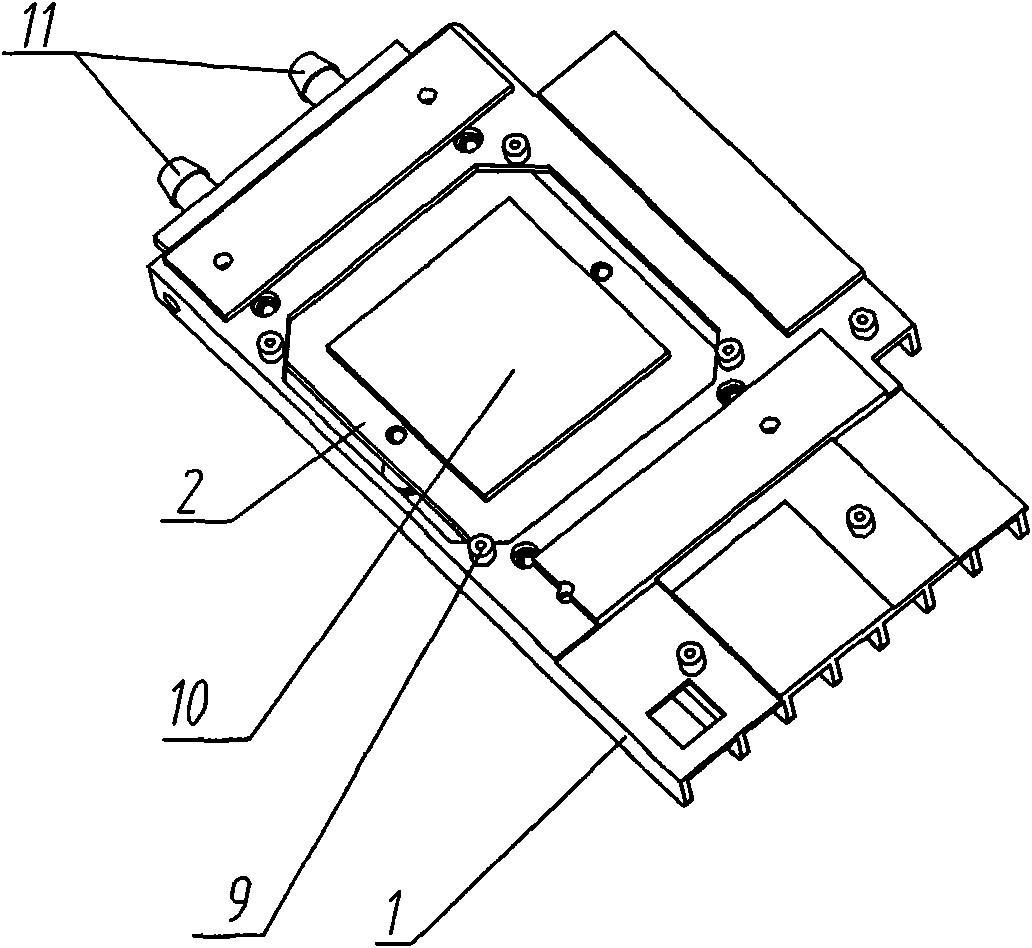

[0009] See figure 1 , figure 2 , which includes a connecting piece, a copper plate 2, a graphics card, and a graphics card chip. The connecting piece is specifically a lower inlay block 1, which is connected to a graphics card, and a red copper plate 2 is installed on the non-graphics card contact surface side of the hollow in the middle of the lower inlay block 1. One side of the copper plate 2 protrudes from the hollow part of the lower insert to contact the graphics card chip, and the other side of the copper plate 2 is mounted on the cooling surface of the semiconductor cooling plate 5, and the hot surface of the semiconductor cooling plate 5 is in plane contact with the exchanger 7. The exchanger 7 is equipped with an external pipeline connection 11 . The protruding part of one side of the copper plate 2 is coated with thermally conductive adhesive 10, and the other side of the thermally conductive adhesive 10 is in plane contact with the graphics card chip. The copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com