A kind of high temperature acidifying corrosion inhibitor and preparation method thereof

A technology of acidizing corrosion inhibitor and corrosion inhibitor, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of operator's health damage, unsafe production process, increase of unit consumption of benzyl chloride, etc. Reduce production costs, reduce usage, and avoid the effect of self-condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

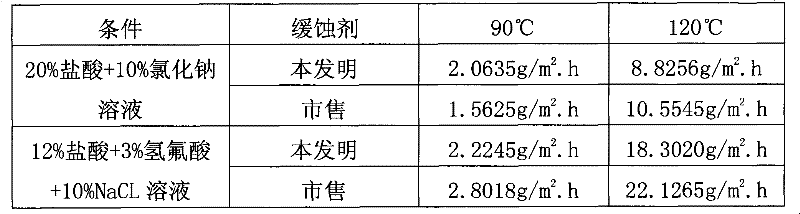

Examples

Embodiment 1

[0028] Example 1, take the following raw materials in parts by weight to produce a high-temperature acidification corrosion inhibitor, 79.33 parts of ethanol, 19 parts of formic acid, 22.33 parts of aniline, 31.11 parts of acetophenone, 26.13 parts of formaldehyde, 31.54 parts of benzyl chloride and 8.55 parts of propynyl alcohol share.

[0029] Produce according to the following process steps:

[0030] 1) The raw materials are prepared in parts by weight, and the formaldehyde is prepared into an aqueous solution with a concentration of 30%;

[0031] 2) Place ethanol, formic acid and aniline in the reaction kettle and stir for 8 minutes;

[0032] 3) Add acetophenone into the reaction kettle, raise the temperature of the reaction kettle to 80° C., then add formaldehyde solution to the reaction kettle dropwise, and the dropping time is 20 minutes;

[0033] 4) After adding the formaldehyde solution dropwise, control the temperature of the reactor at 80±0.5°C for 3 hours;

[00...

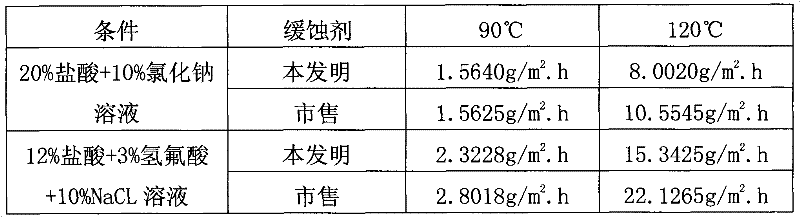

Embodiment 2

[0039] Embodiment 2, get the raw material production high temperature acidification corrosion inhibitor of following parts by weight, ethanol 83.5 parts, formic acid 20 parts, aniline 23.5 parts, acetophenone 32.75 parts, formaldehyde 27.5 parts, benzyl chloride 33.2 parts and propynyl alcohol 9 share.

[0040] Produce according to the following process steps:

[0041] 1) The raw materials are prepared in parts by weight, and the formaldehyde is prepared into an aqueous solution with a concentration of 30%;

[0042] 2) Place ethanol, formic acid and aniline in the reaction kettle and stir for 12 minutes;

[0043] 3) Add acetophenone into the reaction kettle, raise the temperature of the reaction kettle to 81° C., and then add formaldehyde dropwise to the reaction kettle for 30 minutes;

[0044] 4) After adding formaldehyde dropwise, control the temperature of the reactor at 78±0.5°C for 4 hours;

[0045] 5) Add benzyl chloride into the reactor, and control the temperature o...

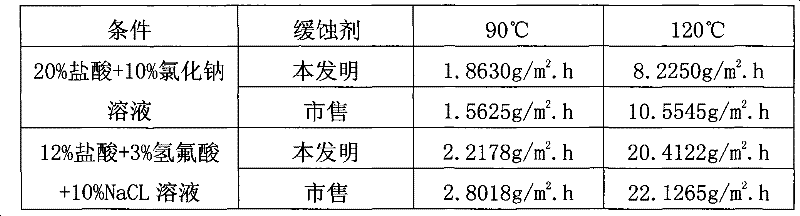

Embodiment 3

[0050] Embodiment 3, take the raw material of following parts by weight to produce high-temperature acidification corrosion inhibitor: 87.68 parts of ethanol, 21 parts of formic acid, 24.68 parts of aniline, 34.39 parts of acetophenone, 28.88 parts of formaldehyde, 34.86 parts of benzyl chloride and 9.45 parts of propynyl alcohol share.

[0051] Produce according to the following process steps:

[0052] 1) The raw materials are prepared in parts by weight, and the formaldehyde is prepared into an aqueous solution with a concentration of 30%;

[0053] 2) Place ethanol, formic acid and aniline in the reaction kettle and stir for 18 minutes;

[0054] 3) Add acetophenone into the reaction kettle, raise the temperature of the reaction kettle to 82° C., then add formaldehyde solution dropwise to the reaction kettle, and the dropping time is 40 minutes;

[0055] 4) After adding the formaldehyde solution dropwise, control the temperature of the reactor at 77±0.5°C for 5 hours;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com