Preparation method of direct crosslinking proton exchange membrane

A proton exchange membrane and cross-linking technology, applied in chemical instruments and methods, membrane technology, organic membranes, etc., can solve problems such as poor controllability of sulfonation degree, complicated process, and polymer main chain breakage, etc., to avoid Molecular chain breaks, simple synthesis process, and good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Synthesis of SDFDPS / DFDPS-THB (5 / 5-5%) polymer, crosslinking agent THB content is 5%, IEC=2.11mmol / g

[0065] Add 2.051g (4.475mmol) SDFDPS, 1.138g (4.475mmol) DFDPS, 1.542g (8.278mmol) BP and 0.056g (0.448mmol) THB into a constant pressure Add 24ml of DMSO to the dropping funnel and the four-necked flask with nitrogen inlet and outlet, and after it is completely dissolved, add 1.422g of anhydrous potassium carbonate and 12ml of anhydrous toluene. The temperature was raised to 140° C. for 4 hours, and the water produced in the reaction was removed by constant boiling with toluene. Then the temperature was raised to 165° C., and 12 ml of anhydrous toluene was added dropwise through a constant pressure dropping funnel. React for 8 hours. After the reaction, add about 20ml of DMAc to dilute, lower the temperature, pour into about 500ml of pure water, precipitate fibrous products, wash thoroughly with water, and vacuum dry at 100°C for 24 hours to obtain a directly cross-...

Embodiment 2

[0068] Preparation of SFDFDPS / DFDPS-THB (5 / 5-5%) proton-type membrane (M1).

[0069] Weigh 2.0 g of SFDFDPS / DFDPS-THB (5 / 5-5%) polymer, add 50 ml of DMSO, and heat to dissolve. After filtration, it was poured on a glass plate. Dry at 80°C, 100°C, and 120°C for 2 hours respectively, and then rise to 140°C for 20 hours. Take it out, soak it in water and peel it off, soak it in water for 24 hours, then exchange it with 2M hydrochloric acid solution for 72 hours, take it out, and wash it with water for 48 hours. It was taken out and dried at 150° C. for 2 hours to obtain a proton type sulfonated polymer membrane.

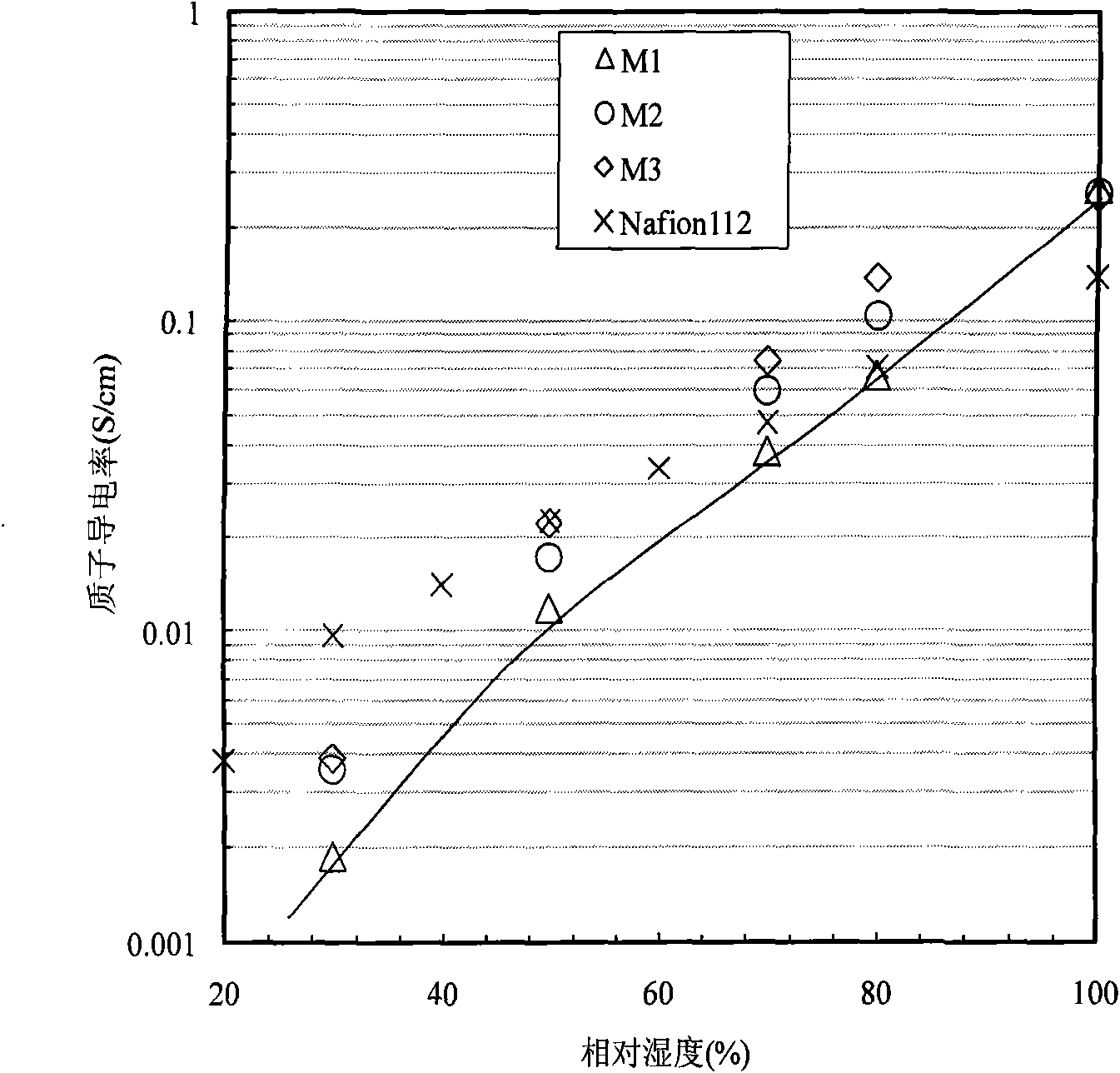

[0070] Its performance data is shown in Table 1, and the conductivity under different relative humidity is shown in figure 2 .

Embodiment 3

[0072] Synthesis of SDFDPS / DFDPS-THB (6 / 4-5%) polymer, crosslinking agent THB content 5%, IEC=2.43mmol / g

[0073] Add 1.902g (4.149mmol) of SDFDPS, 0.703g (2.766mmol) of DFDPS, 1.192g (6.397mmol) of BP and 0.044g (0.346mmol) of THB into a tank equipped with a stirring device, an oil-water separator, a reflux condenser, and a constant pressure drop Add 19ml of DMSO to the liquid funnel and the four-neck flask with nitrogen inlet and outlet, and after it is completely dissolved, add 1.099g of anhydrous potassium carbonate and 10ml of anhydrous toluene. The temperature was raised to 140° C. for 4 hours, and the water produced in the reaction was removed by constant boiling with toluene. Then the temperature was raised to 165° C., and 10 ml of anhydrous toluene was added dropwise through a constant pressure dropping funnel. React for 8 hours. After the reaction, add about 15ml of DMAc to dilute, lower the temperature, pour into about 500ml of pure water, precipitate fibrous prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com