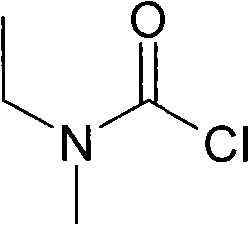

Method for preparing ethylmethylamino formyl chloride

A technology of ethyl methyl carbamoyl and ethyl formamide is applied in the field of preparation of ethyl methyl carbamoyl chloride, can solve problems such as excessive length, and achieve the effects of short route, reduction of reaction steps and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

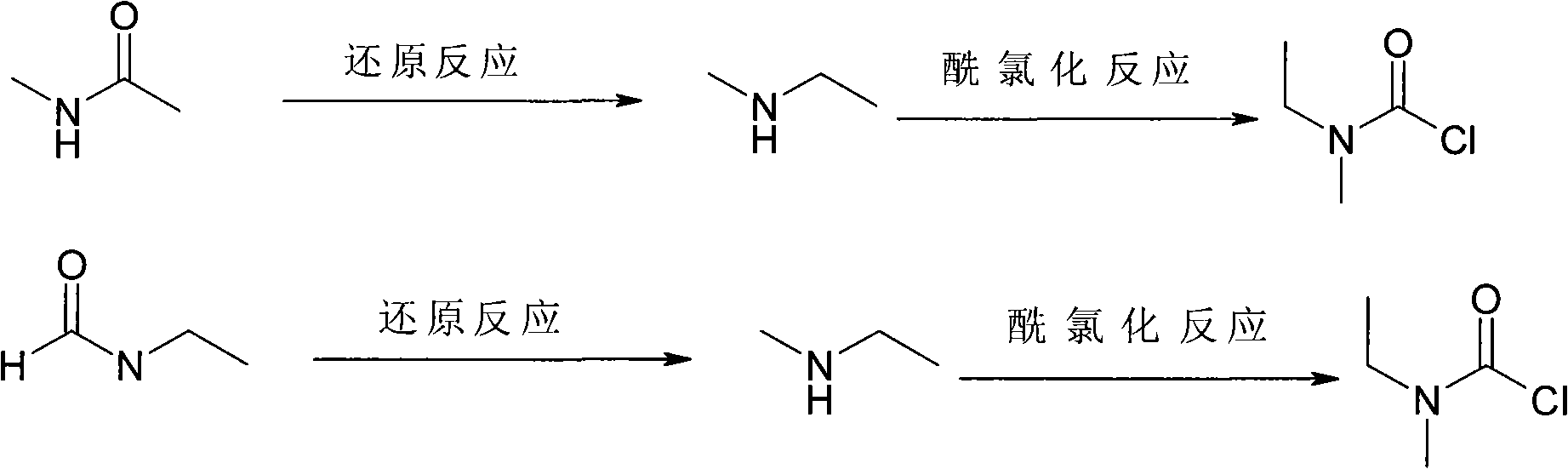

[0027] (1) the preparation of methylethylamine:

[0028] Put 120ml of tetrahydrofuran and 120ml of toluene into a clean and dry 1000ml four-necked flask, cool it to 0°C with ice water, slowly add 156g of zinc chloride in batches, the heat release is violent, and after feeding, add N-methyl Add 60g of acetamide, drop it in about 30 minutes, then add 57.6g of potassium borohydride, and then stir for 30 minutes near 0°C, then remove the ice bath, stir at room temperature and naturally raise the temperature for 1 hour, then heat to 40°C and keep it for 1.5 hours. After the heat preservation is completed, slowly raise the temperature to reflux for 3 hours (in the heat preservation process, the method of gradually raising the temperature is adopted to let itself release heat and then heat up, which can effectively prevent the occurrence of material flushing and ensure the safety of the operation), after the heat preservation is completed, steam it out under normal pressure The solve...

Embodiment 2

[0032] (1) the preparation of methylethylamine:

[0033] Put 120ml of tetrahydrofuran and 120ml of benzene into a clean and dry 1000ml four-necked flask, cool it to 0°C with ice water, slowly add 156g of zinc chloride in batches, the heat release is violent, and after feeding, add N-methyl chloride dropwise at this temperature Add 60g of acetamide, drop it in about 30 minutes, then add 80g of potassium borohydride, and then stir for 30 minutes near 0°C, then remove the ice bath, stir at room temperature and naturally heat up for 1 hour, then heat to 40°C for 1.5 hours, keep warm After finishing, slowly heat up to reflux and keep warm for 3 hours. After the heat preservation is completed, about 120ml of the solvent is evaporated under normal pressure. After the evaporation is completed, the pH is adjusted to 2~3 with hydrochloric acid. The sodium oxide solution was used to adjust the pH to 14. After the adjustment, the temperature was raised again, and the liquid at 50-80° C. ...

Embodiment 3

[0037] (1) the preparation of methylethylamine:

[0038] Put 240ml of toluene into a clean and dry 1000ml four-necked flask, cool it to 0°C with ice water, slowly add 156g of zinc chloride in batches, the heat release is violent, after feeding, add 60g of N-ethylformamide dropwise at this temperature After dripping in about 30 minutes, add 46.8g of sodium borohydride, and then stir for 30 minutes near 0°C, then remove the ice bath, stir at room temperature and naturally raise the temperature for 1 hour, then heat to 40°C and keep it for 1.5 hours. Slowly heat up to reflux for 3 hours. After the heat preservation is completed, about 120ml of the solvent is evaporated under normal pressure. After the evaporation is completed, the pH is adjusted to 2~3 with hydrochloric acid. The potassium oxide solution was adjusted to pH=14. After the adjustment, the temperature was raised again, and the liquid at 50-80° C. was collected, which was methylethylamine, and 38 g of methylethylamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com