Nuclear shell structure Pb-free solder ball for electronic packaging and preparation method thereof

A lead-free solder ball, core-shell structure technology, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of lack of core-shell structure, cooling speed reduction, small solder ball diameter, etc., to achieve high conductivity and high heat The effect of high conductivity and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

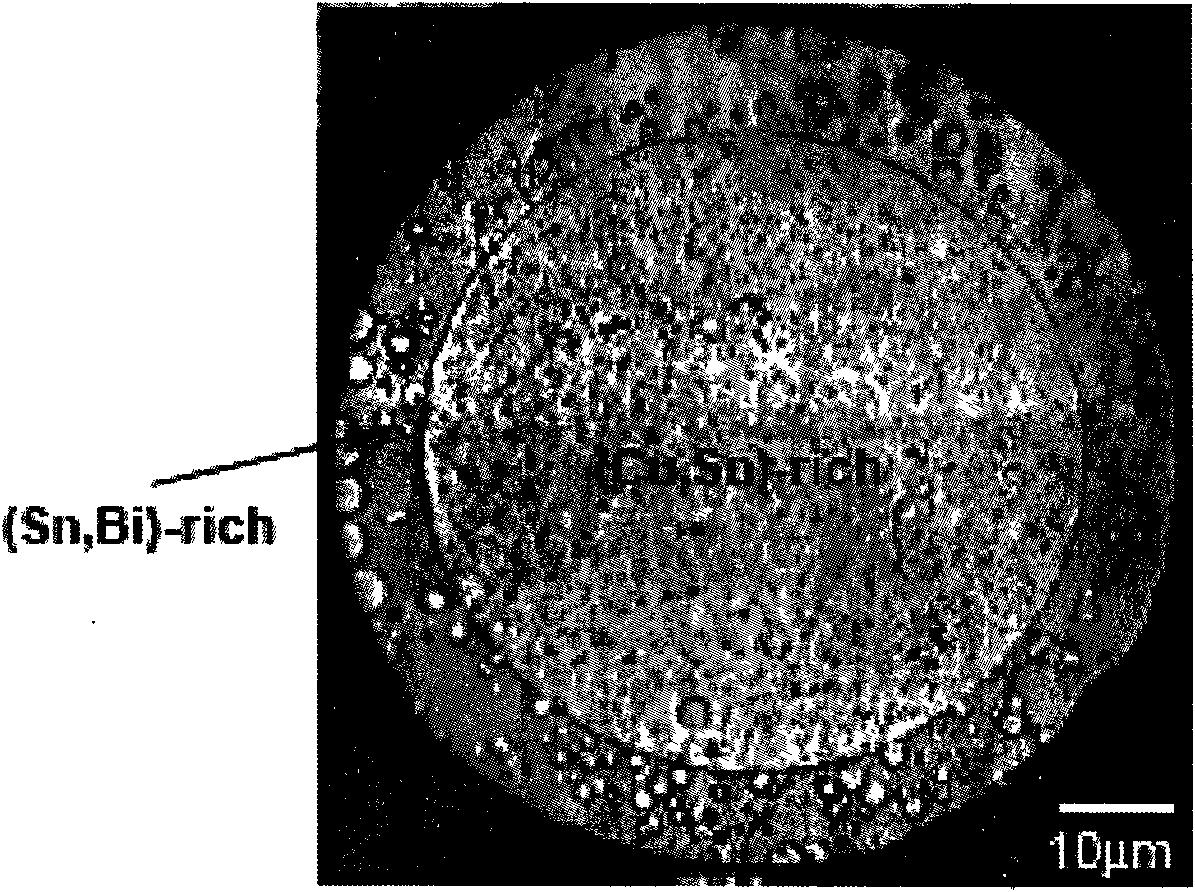

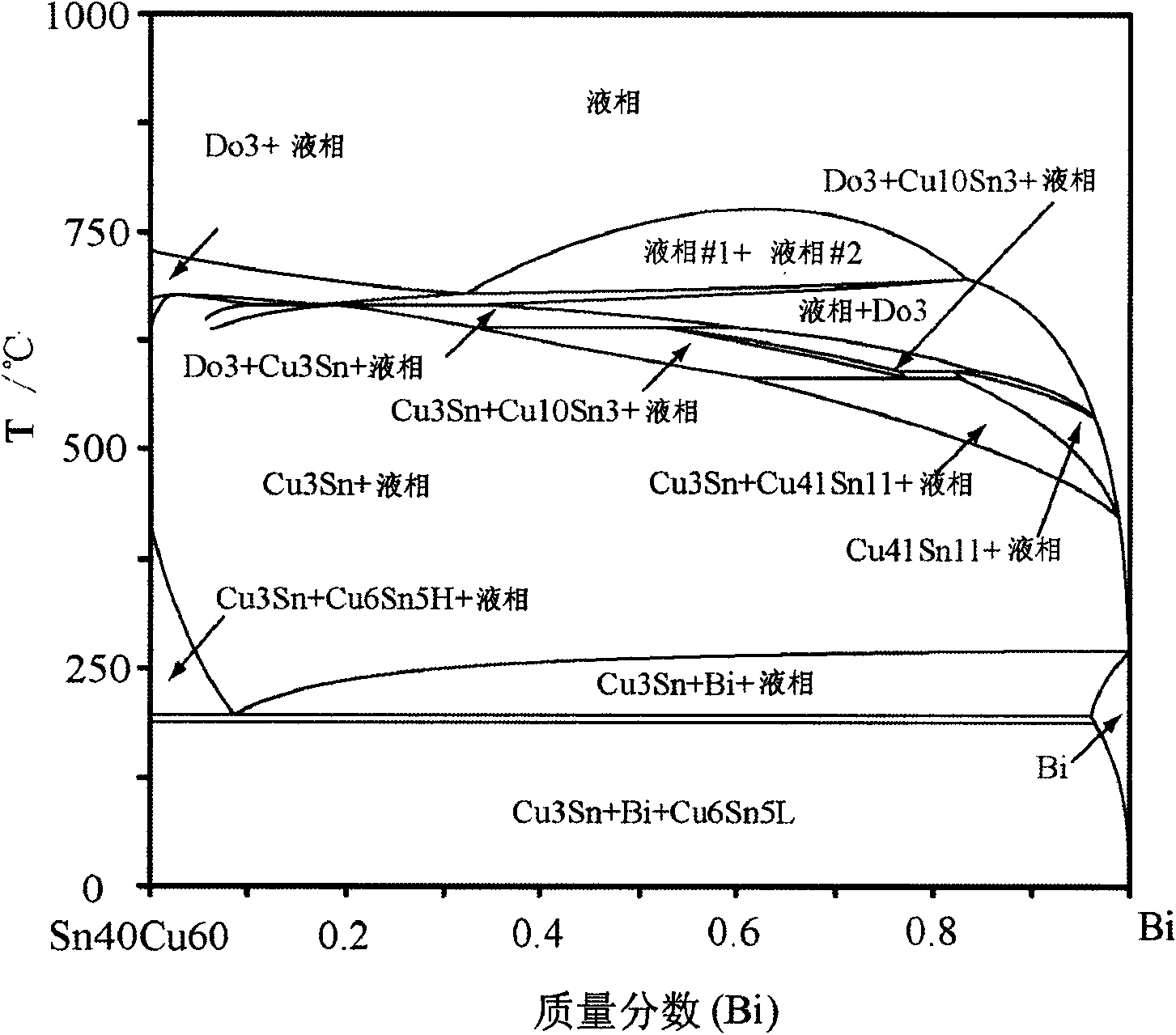

[0028] The alloy was melted in two steps. The first step is to weigh the metal Cu and Sn according to the weight ratio of 3:2, put them into the induction melting furnace, pass in argon gas, heat up to 1100°C to melt the alloy and then cool it down, repeat 3 times until the mixture is uniform; the second step , Weigh the Bi block according to the ratio of CuSn alloy 1:1.5. The rare earth metals that can effectively promote the formation of the core-shell structure include the pure metals and their mixtures listed in the table below, the addition of which is 0.05% (mass fraction), metal Bi, rare earth metals and pre-melted Cu-Sn alloy blocks are smelted again , the maximum temperature is 800°C.

[0029]

[0030] (2) Gas atomization

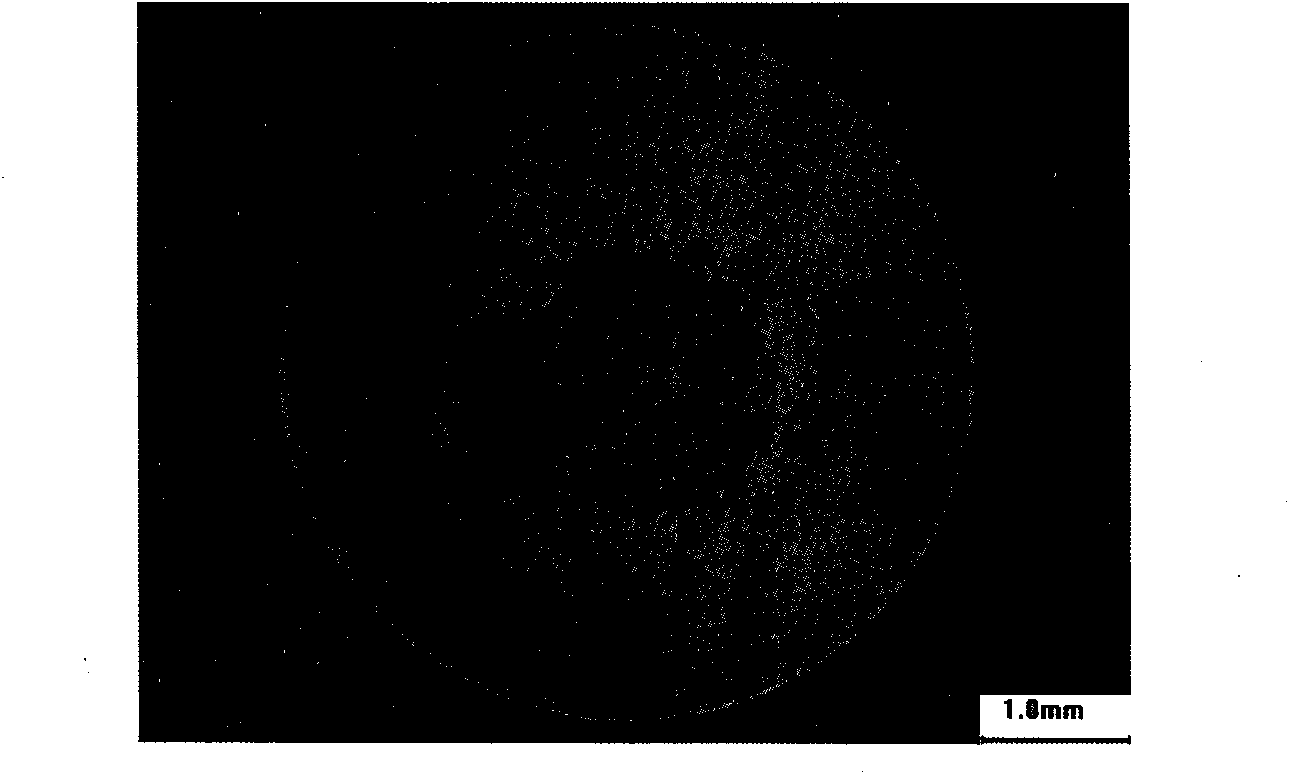

[0031] The uniformly melted alloy melt is atomized into liquid droplets by 0.2MPa high-pressure argon gas, cooled and solidified in the atomization tank to form a complete solder ball.

[0032] (3) Collect, wash, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com